Method of operating an internal combustion engine

A technology of internal combustion engine and operating mode, applied in the direction of internal combustion piston engine, combustion engine, mechanical equipment, etc., can solve the problems of increasing cost and complexity, difficulty in installing the limited space of engine combustion chamber, etc., and achieve the effect of cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

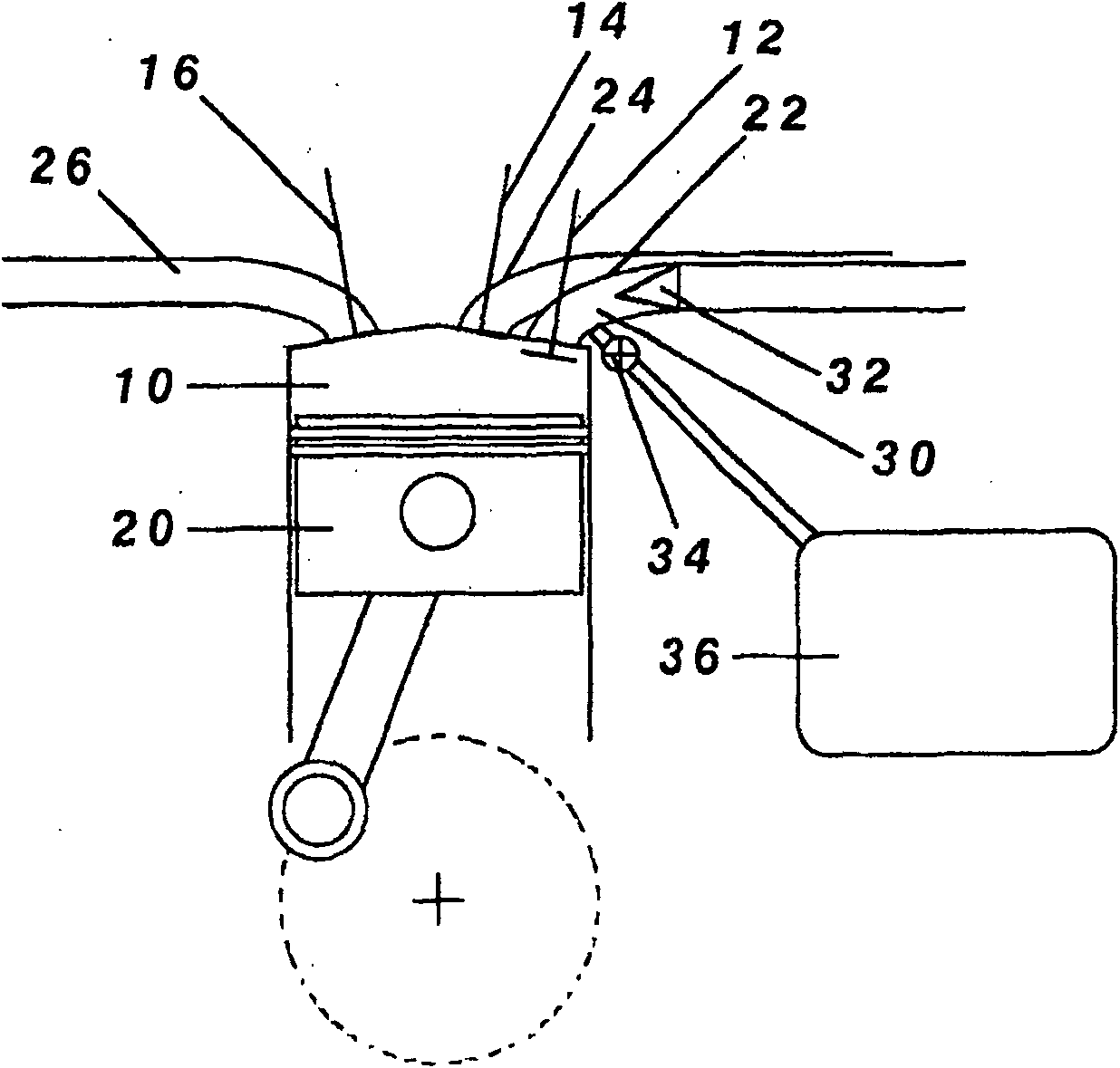

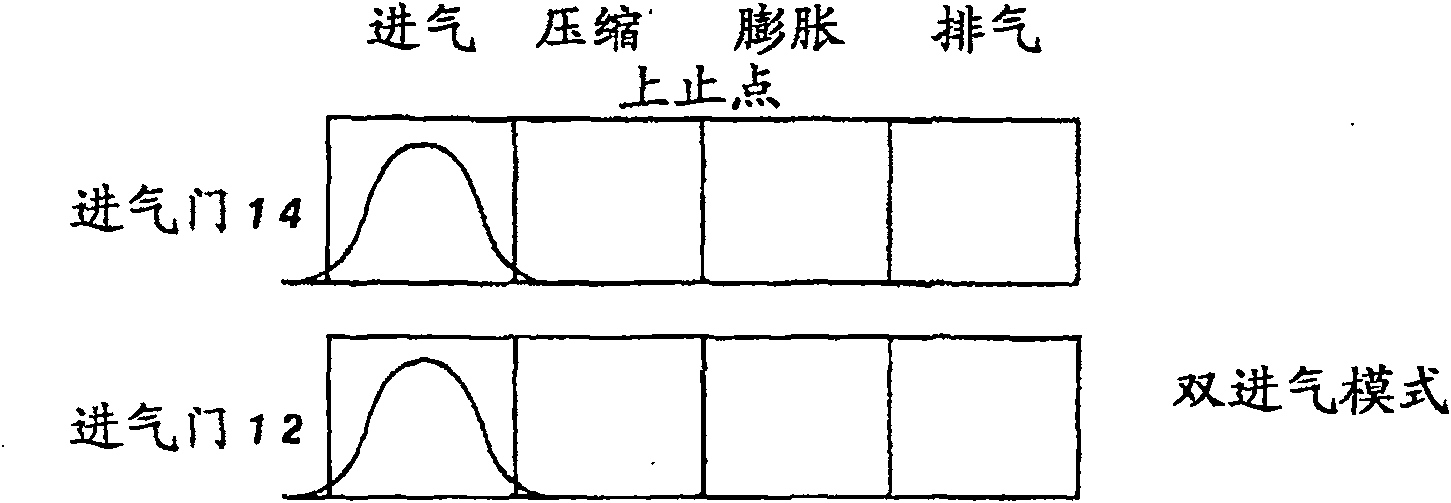

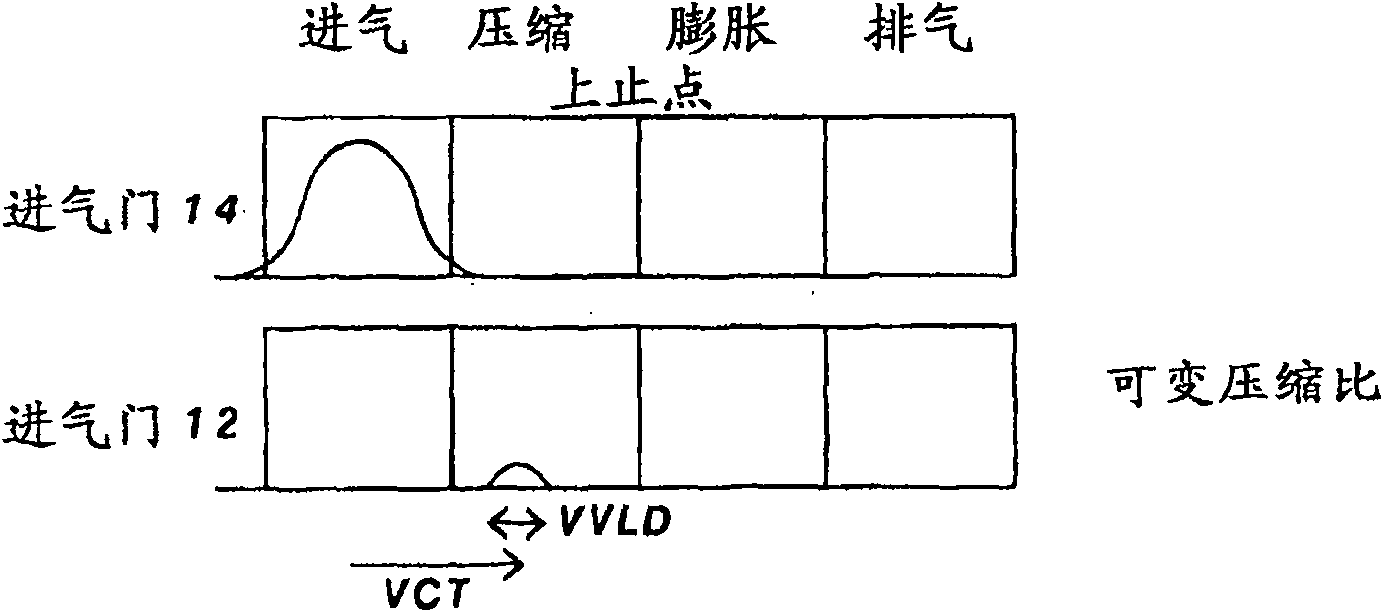

[0025] figure 1 An internal combustion engine is shown having first and second intake ports 24, 22 in each cylinder working together with an exhaust port 26, where each port is controlled by an associated valve 14, 12, 16 , these valves are timed to open and close during the intake or exhaust phases of the engine cycle to control the intake and exhaust of the engine. In the second air inlet 22 there is additionally a one-way reed valve 32 positioned in such a way that when the air inlet 22 and the one-way valve 32 are controlled by the arm from the local area where the delivery pressure from the ambient air is high Pressure, the valve 32 automatically closes in a direction away from the engine cylinder 10 . The engine also includes a fuel system and an ignition system, not shown.

[0026] In the above engine, a variable valve actuation system (not shown) is provided for the intake valves 12 , 14 . This is completely flexible and variable as in an electronically controlled c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com