Method for manufacturing driveway module, and driveway module

A technology of rails and trains, applied in the field of steel driving rail modules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

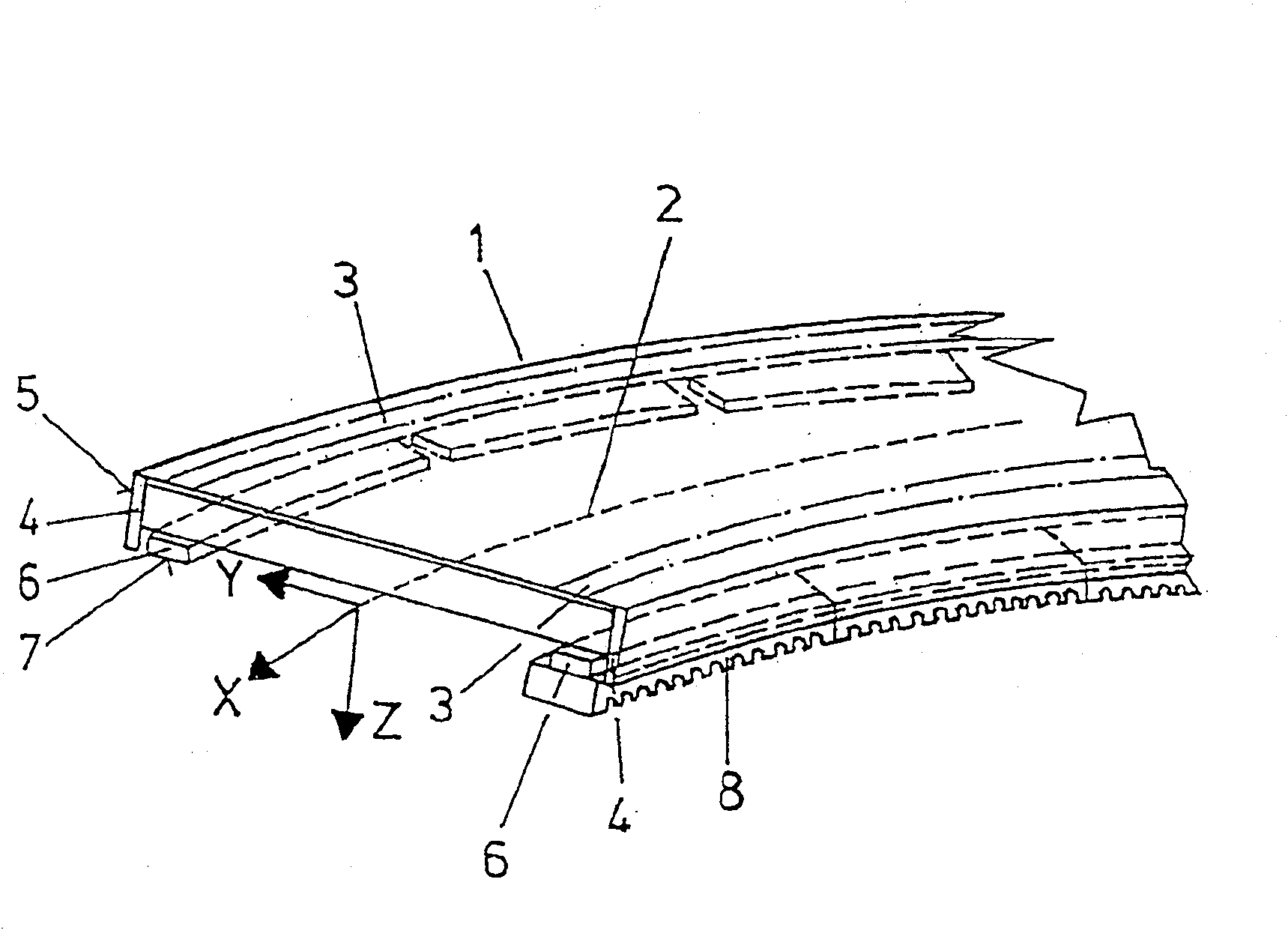

[0035] figure 1 An idealized representation of a steel track module 1 is shown, which is suitable for building the track of a maglev railway with a long stator linear field motor. This exemplary embodiment is a module 1 which is curved completely along a predetermined railway line, as indicated by a spatial curve 2 which is shown in the plane. Furthermore, a rectangular coordinate system with mutually perpendicular axes x, y and z is shown schematically. where curvature around the x-axis means a lateral inclination in the sense of a curve superelevation, curvature around the y-axis means a section of roadway passing through a rounded crest or a valley and curvature around the z-axis means a curve drive.

[0036] The module 1 has on its upper side two parallel, substantially horizontally arranged and serves as part of the sliding surface 3 and on its longitudinal sides two substantially vertical side rails 4 which are provided with side guide surfaces 5 on their outer sides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com