Electric desalting/dewatering device with efficient combined electrode

A combined electrode and electric desalination technology, applied in the direction of electric/magnetic dehydration/emulsification, etc., can solve the problems of electric dehydration desalters that are not suitable for large diameters, excessive water content after dehydration, and uneven electric field, etc., to achieve increased space , Reduce the back-mixing effect and improve the effect of floating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

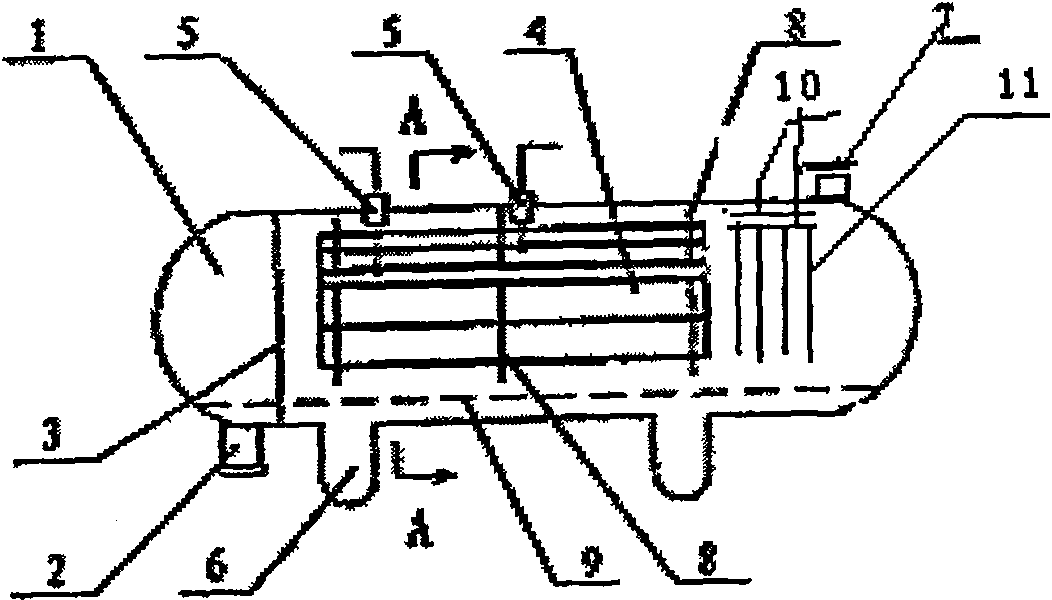

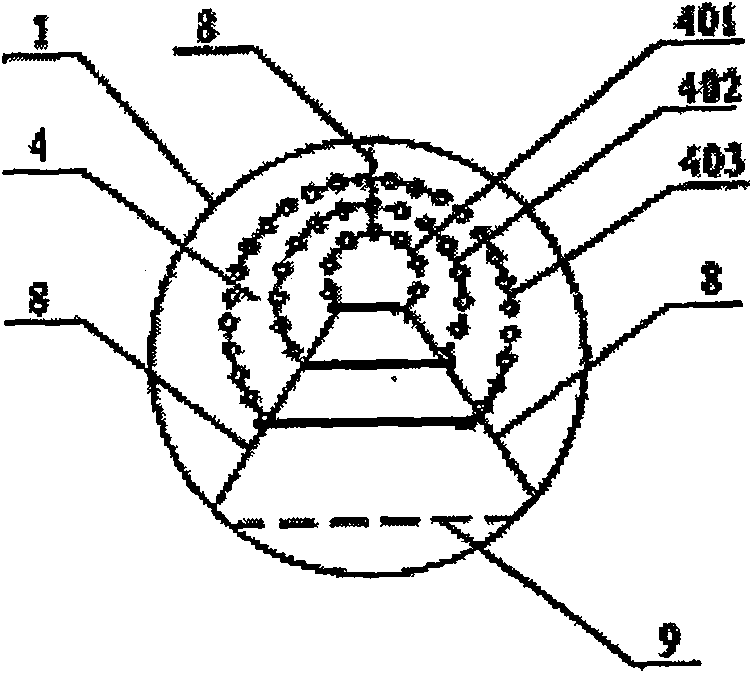

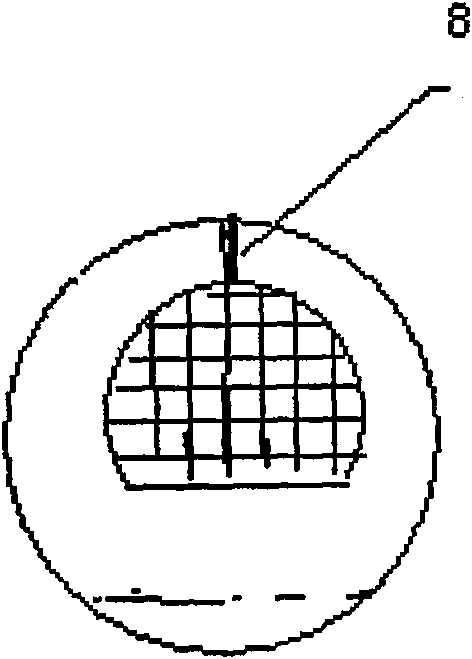

[0015] The operation of this embodiment is as follows: the oil-water mixture enters the tank body 1 from the inlet pipe 2, enters the electrode assembly 4 through the distributor 3, dehydrates and desalts in the annular electric field of the electrode assembly 4, and passes through the electrode assembly at the outlet end. The arcuate mesh of piece 11 is perpendicular to the strong electric field between the cross-section plates for further dehydration. In the electric field, the oil-water mixture material flows horizontally from the inlet end to the outlet end; the falling water droplets descend along the oil flow direction in a horizontal parabolic trajectory, pass through the gaps of electrodes of each layer, and deposit on the bottom of the tank body 1 and in the water bag 6, and then It is discharged from the water bag 6. The dehydrated and desalted oil is extracted through the outlet pipe 7. Since the oil may contain solid impurities, a water flushing device can be inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com