Aerial engine lean premixed preevaporated low contamination combustion chamber

A technology for aero-engines and combustion chambers, applied in combustion chambers, continuous combustion chambers, combustion methods, etc., can solve problems such as difficulty in achieving low-pollution combustion, uneven local equivalent ratio, etc., and achieve improved wall-beating effect, wide stability and low pollution The effect of reducing emissions and pollution emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

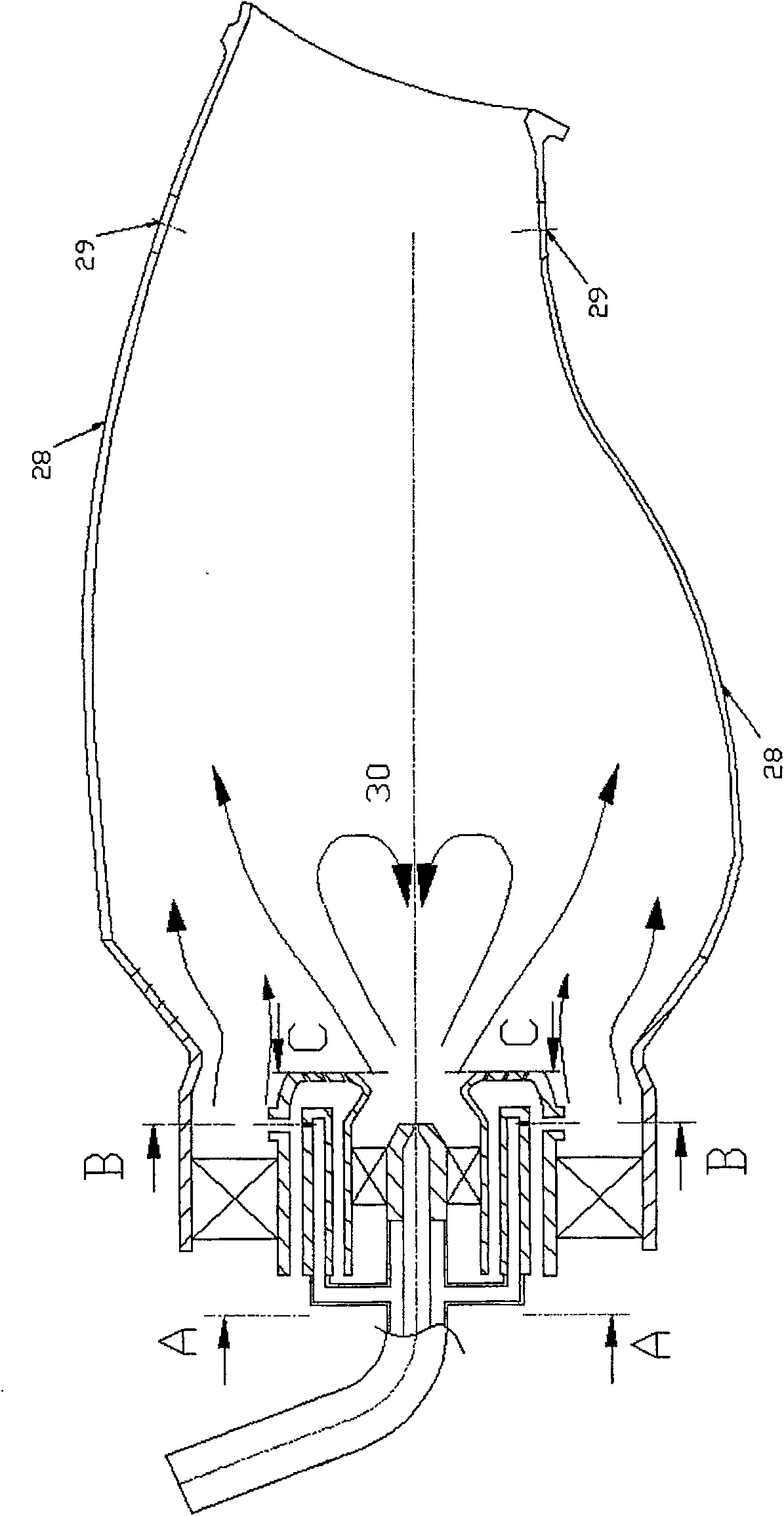

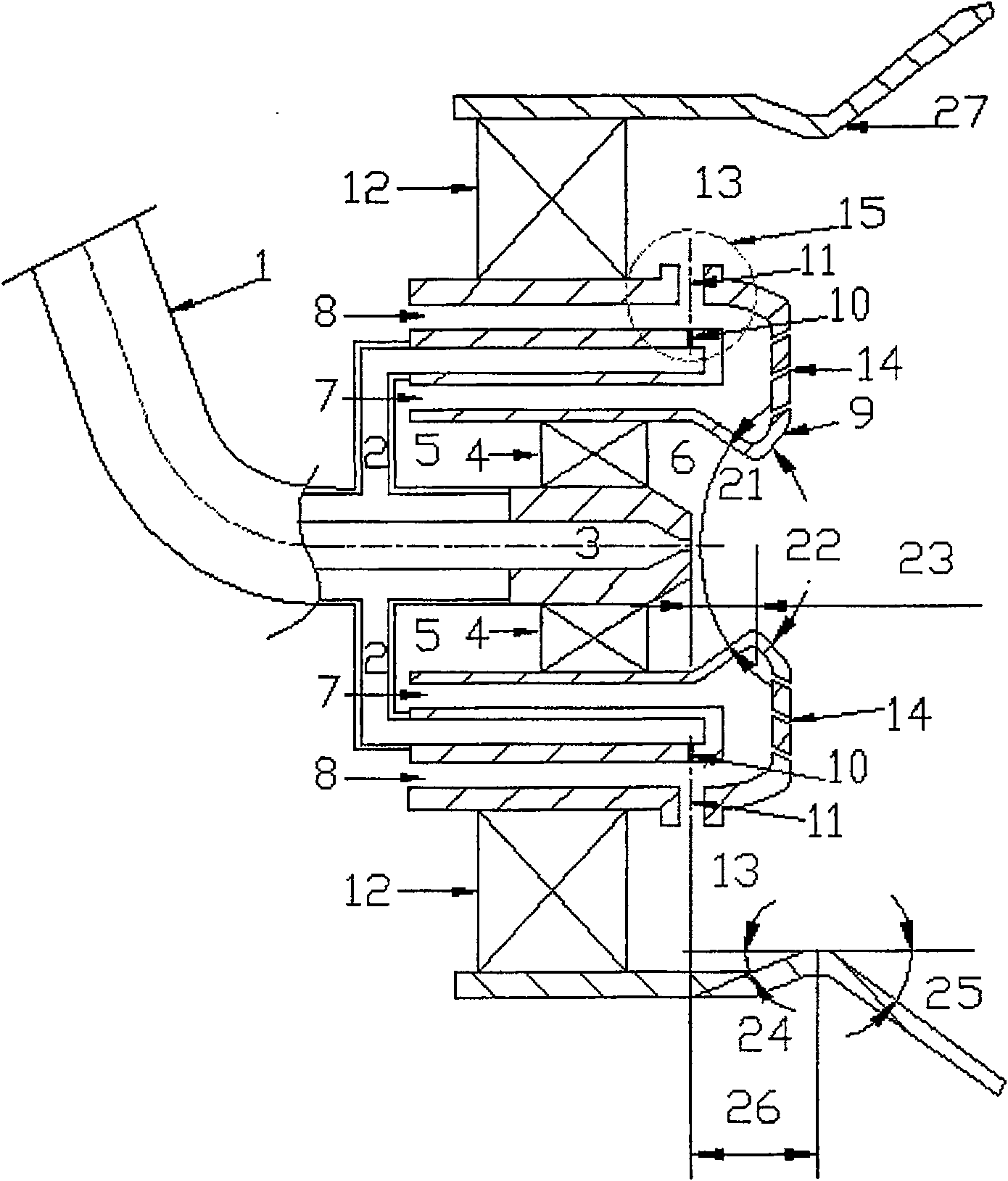

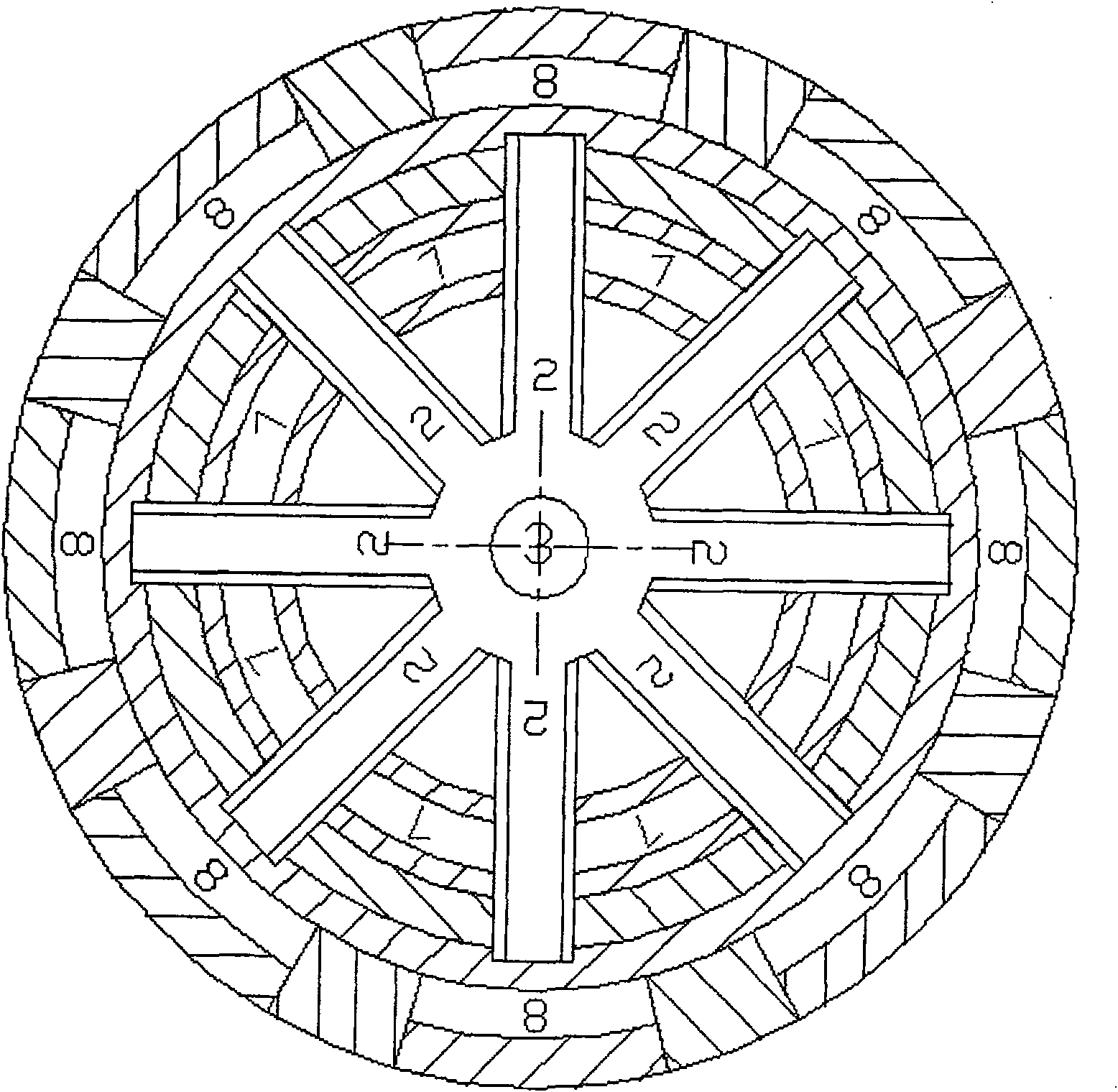

[0024] Such as figure 1 , 2, shown in 3, the combustor of the present invention design is made up of head and flame tube, combustion gas is all supplied from head, other gas is all supplied from flame tube, and mixing hole 29 is set at flame tube rear end To adjust the outlet temperature distribution of the combustion chamber. The main structure of the head is a circular annular cavity structure, which is divided into a pre-combustion stage and a main combustion stage. The pre-combustion stage includes a centrifugal nozzle 3 and a swirler 4 surrounding the centrifugal nozzle; the main combustion stage surrounds the pre-combustion stage, including Direct air atomizing nozzle 15, main swirler 12 and pre-mixing ring chamber 13. The oil circuit 2 and the oil nozzle 10 of the pre-combustion stage centrifugal nozzle 3 and the main combustion stage air atomizing nozzle 15 can be processed into a whole oil supply, including the mixing nozzle 11 of the direct-injection air atomizing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com