Gas meter movement embedded transmission mechanism

A transmission mechanism, gas meter technology, applied in measuring devices, instruments, liquid/fluid solids measurement, etc., can solve problems such as increased valve cover operating resistance, data errors, failures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

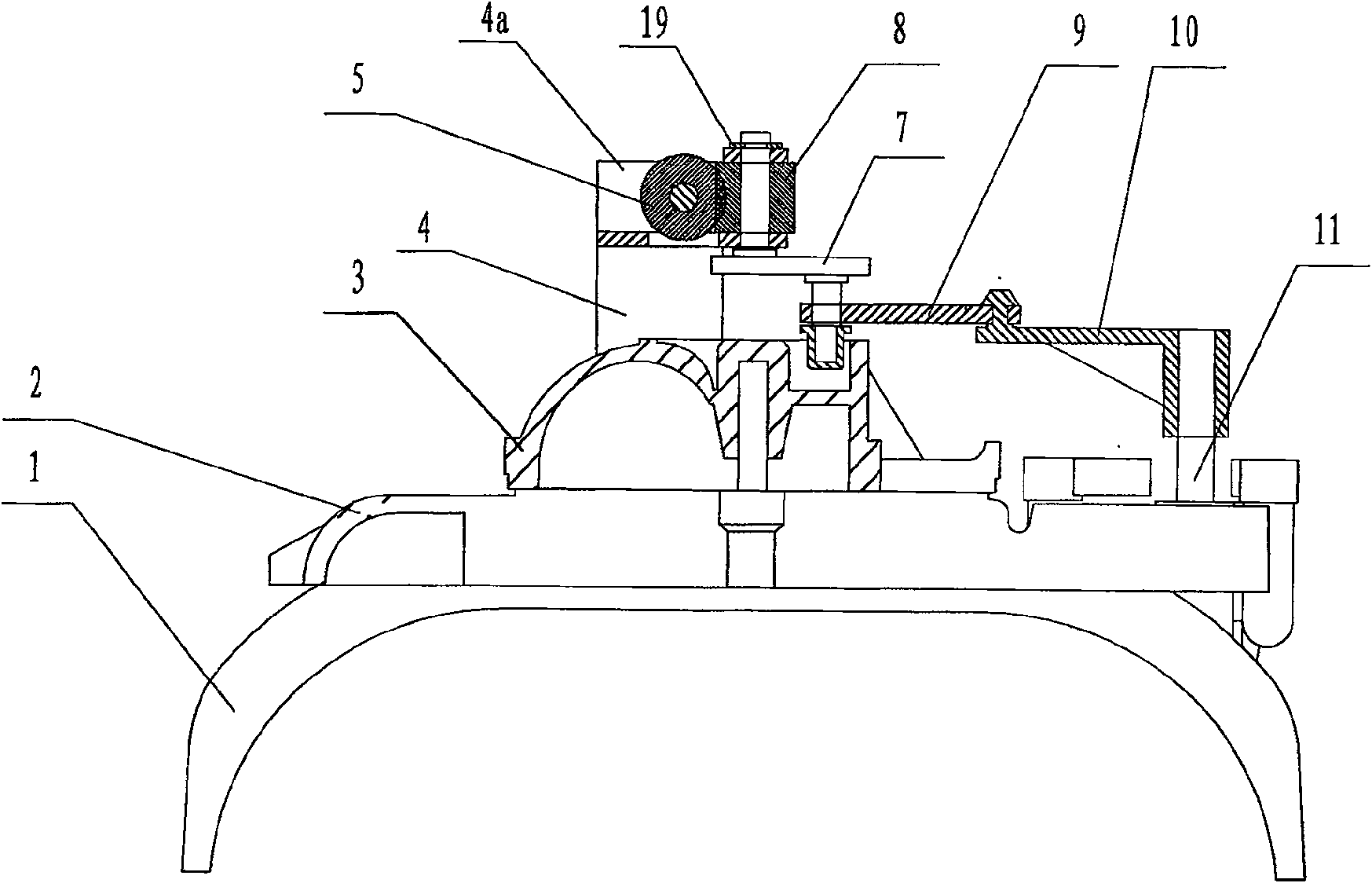

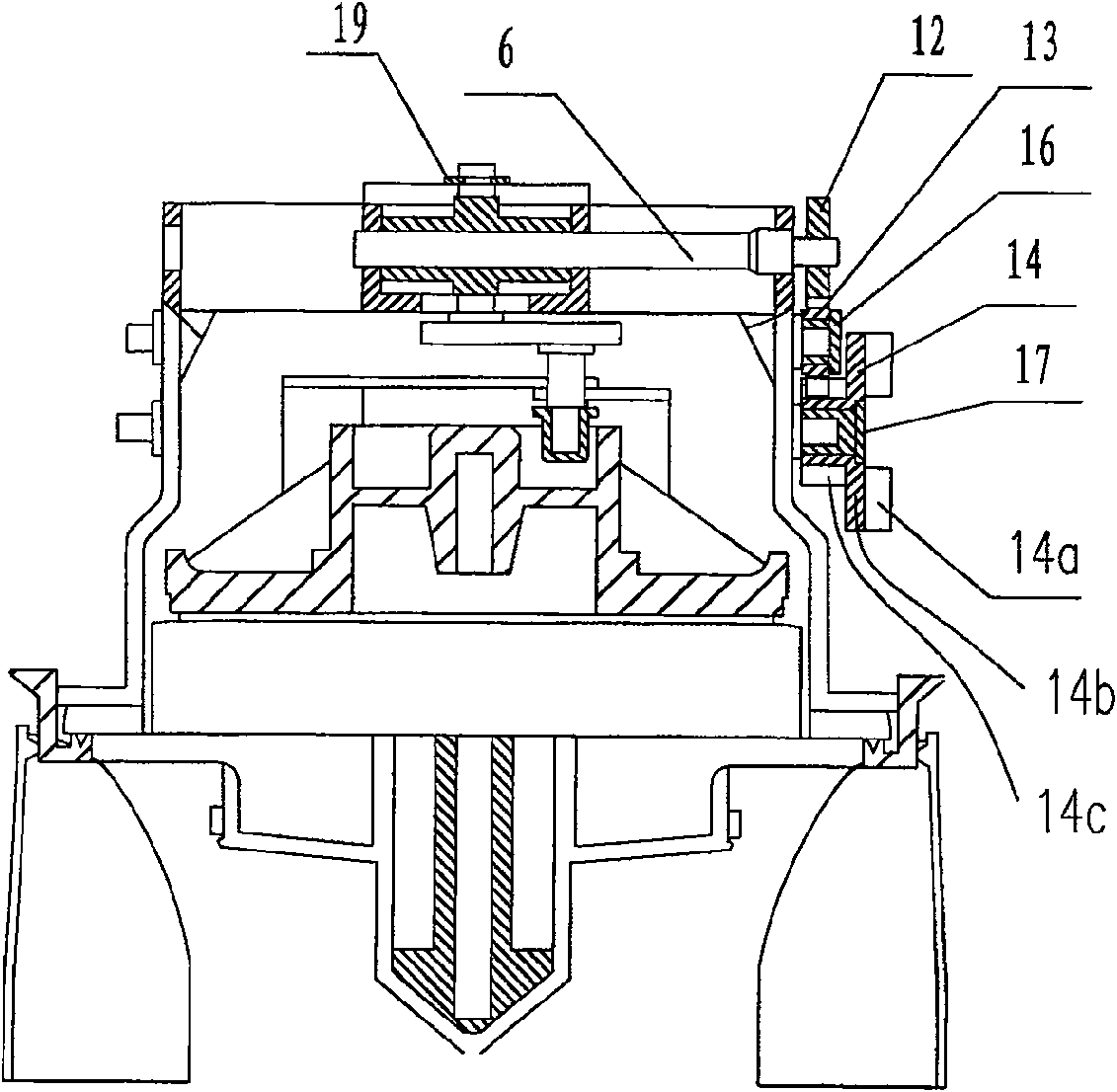

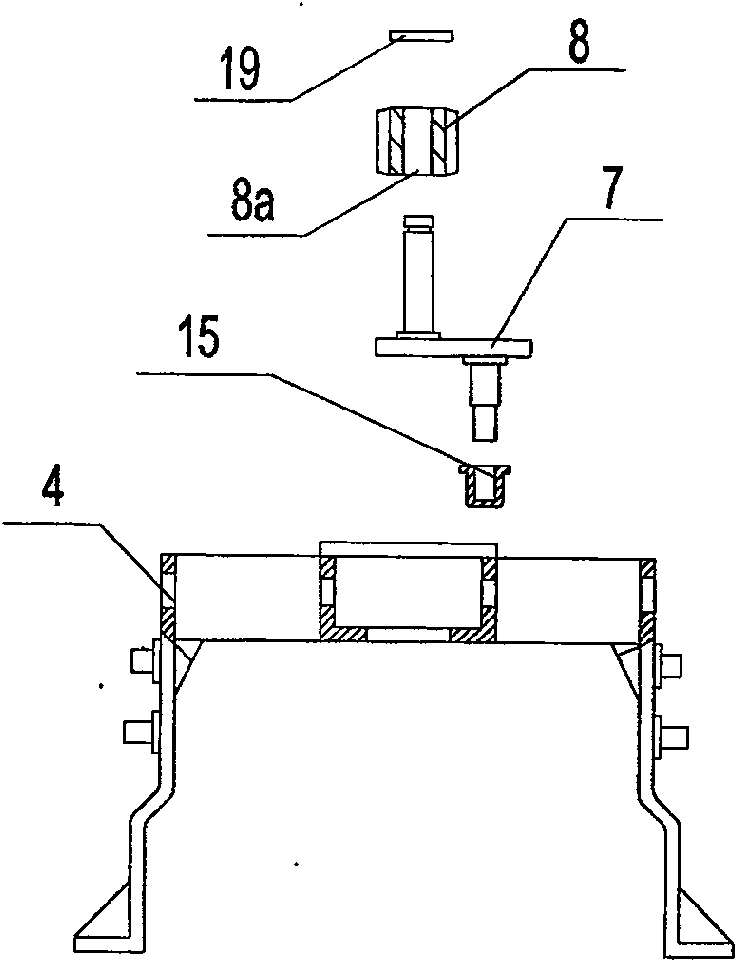

[0019] Example: refer to Figure 1 to Figure 6 , the built-in transmission mechanism of the gas meter core, including the core 1, the valve seat 2 connected to the core 1 and the valve cover 3 cooperating with the valve seat 2, wherein: the core 1 is equipped with a bracket 4; the bracket 4 A worm gear shaft 6 runs through the top; a groove 4a is formed in the middle of the upper end of the bracket 4, and a worm gear 5 with meshing teeth is installed in the groove 4a, and the worm gear 5 is set on the worm gear shaft 6; a semicircular hole 8a is formed on the bracket 4 The worm 8 is engaged with the worm wheel 5; the bottom end of the worm 8 is formed with a rocker 7 protruding to one side; the outer end of the rocker 7 has a shaft structure, and the shaft structure is successively connected with at least two connecting rods 9 The center of rotation of the rocker 7 and the center of rotation of the valve cover 3 are on the same axis; the lower end of the shaft structure of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com