Process of depositiong TiN film on glass substrate

A glass substrate and thin film technology, applied in the field of depositing TiN thin films, can solve the problems of cumbersome operation process and achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

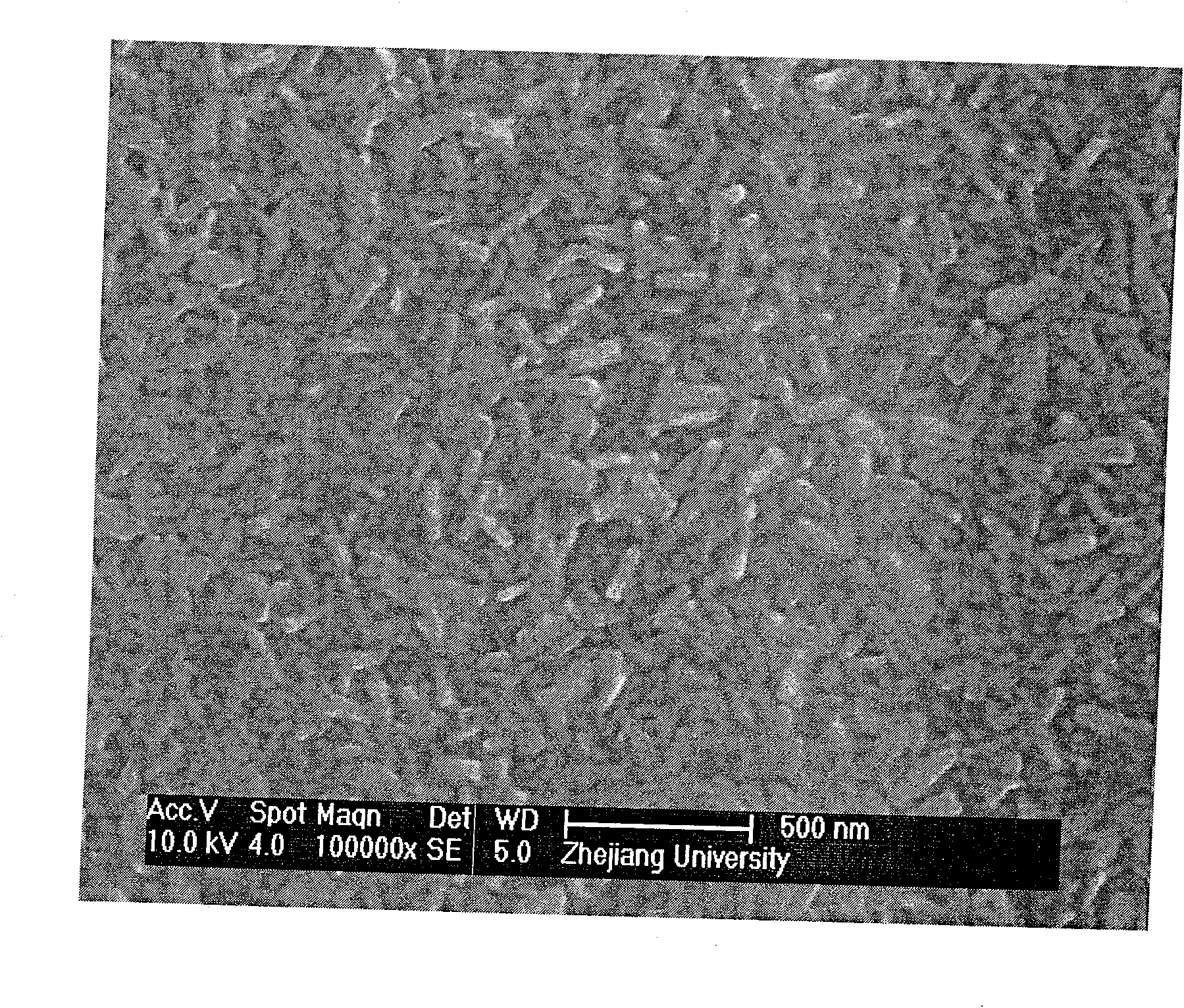

Image

Examples

Embodiment 1

[0016] 1) Clean the glass substrate with 10% hydrofluoric acid;

[0017] 2) Put the glass substrate on the graphite support of the reaction chamber of the chemical vapor deposition device, and the reaction chamber is evacuated to -0.02Mpa, and N 2 Clean the reaction chamber;

[0018] 3) Adjust the distance between the nozzle and the glass substrate to be 5cm;

[0019] 4) Heating the reaction chamber to 600°C;

[0020] 5) TiCl 4 , NH 3 and N 2 The reaction gas is passed into the reaction chamber, where TiCl 4 The flow rate is 300sccm, NH 3 The flow rate is 150sccm, N 2 The flow rate is 900sccm, the pressure of the reaction chamber is -0.02MPa, the deposition is carried out at a temperature of 600°C, and the reaction time is 90s. After the reaction is completed, stop feeding the gas and cool it down.

[0021] The resistivity of the prepared TiN film is 1.5×10 4 μΩ.cm, the reflectivity in the infrared region is 45%, and with the increase of wavelength, the reflectivity o...

Embodiment 2

[0023] 1) Clean the glass substrate with 10% hydrofluoric acid;

[0024] 2) Put the glass substrate on the graphite support of the reaction chamber of the chemical vapor deposition device, and the reaction chamber is evacuated to -0.02Mpa, and N 2 Clean the reaction chamber;

[0025] 3) Adjust the distance between the nozzle and the glass substrate to be 25cm;

[0026] 4) Heating the reaction chamber to 600°C;

[0027] 5) TiCl 4 , NH 3 and N 2 The reaction gas is passed into the reaction chamber, where TiCl 4 The flow rate is 300sccm, NH 3 The flow rate is 150sccm, N 2 The flow rate is 900sccm, the pressure of the reaction chamber is -0.02MPa, the deposition is carried out at a temperature of 600°C, and the reaction time is 90s. After the reaction is completed, stop feeding the gas and cool it down.

[0028] The prepared TiN thin film is non-conductive and has a reflectivity of 35% in the infrared region, and the emissivity of the thin film tends to decrease as the wav...

Embodiment 3

[0030] 1) Clean the glass substrate with 10% hydrofluoric acid;

[0031] 2) Put the glass substrate on the graphite support of the reaction chamber of the chemical vapor deposition device, and the reaction chamber is evacuated to -0.02Mpa, and N 2 Clean the reaction chamber;

[0032] 3) Adjust the distance between the nozzle and the glass substrate to be 13cm;

[0033] 4) Heating the reaction chamber to 600°C;

[0034] 5) TiCl 4 , NH 3 and N 2 The reaction gas is passed into the reaction chamber, where TiCl 4 The flow rate is 300sccm, NH 3 The flow rate is 150sccm, N 2 The flow rate is 900sccm, the pressure of the reaction chamber is -0.02MPa, the deposition is carried out at a temperature of 600°C, and the reaction time is 90s. After the reaction is completed, stop feeding the gas and cool it down.

[0035] The resistivity of the prepared TiN film is 7.5×10 3 μΩ.cm, the reflectivity in the infrared region can reach more than 50%, and it shows an upward trend with the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com