Packaged technology for in situ automatically monitoring underwater groundsill

An automatic monitoring and foundation technology, applied to underwater structures, open-air water source surveys, measuring instruments, etc., can solve problems such as damage to ships or construction machinery, can only be placed on the ground under the water, and difficulty in setting reference points, etc., to achieve The effect of saving monitoring personnel, eliminating the need for round-trip ship machines, and eliminating human-made reading errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0090] (1) Surface subsidence monitoring method for multiple fixed inclinometer sections

[0091] 1. Structure and working principle

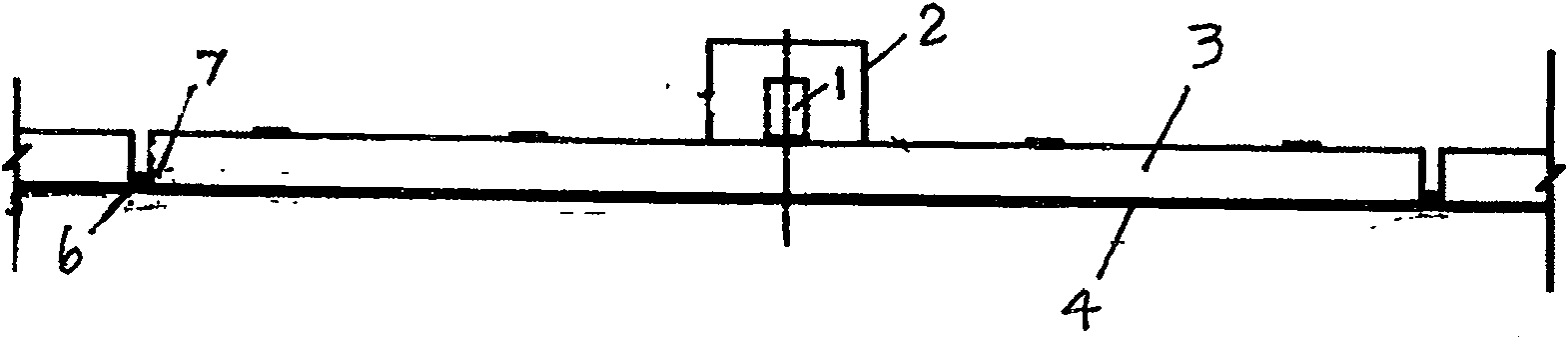

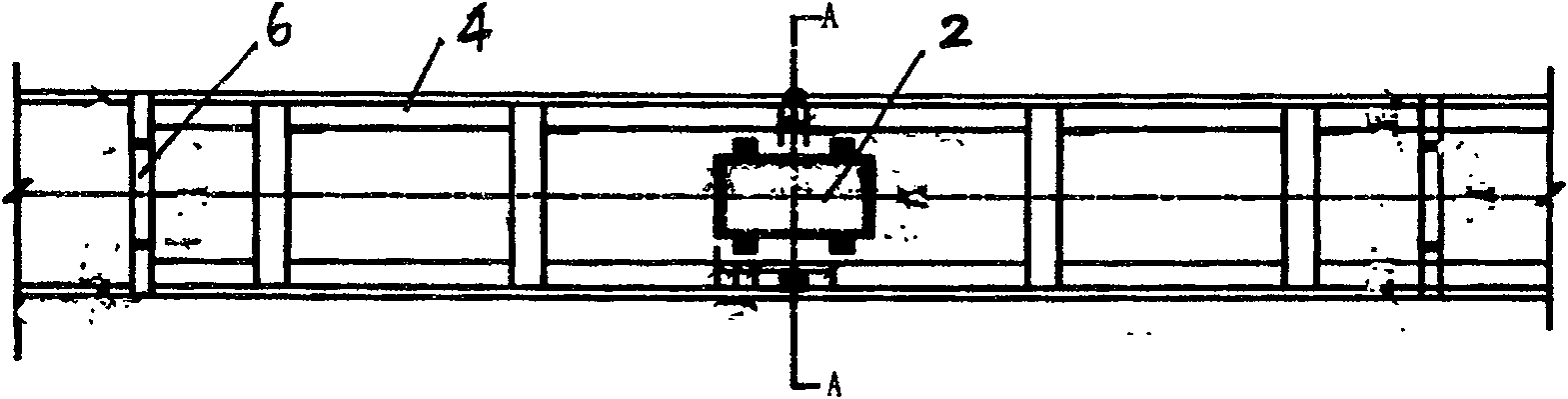

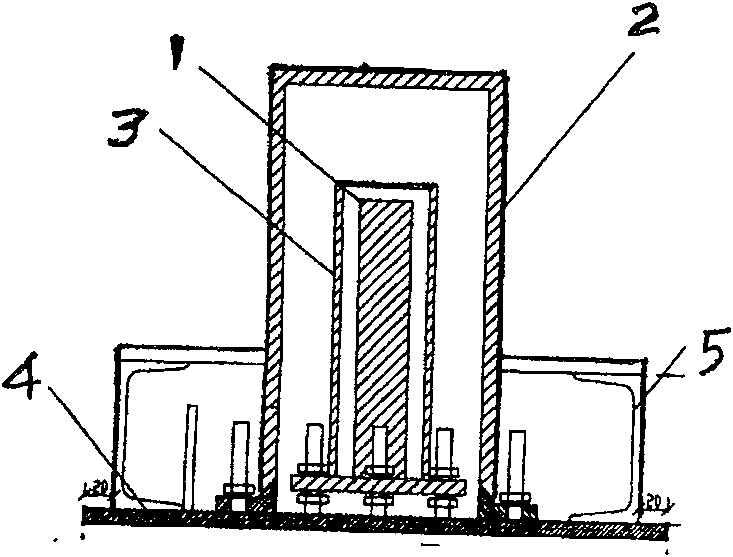

[0092] I propose a method of monitoring cross-section settlement with multiple fixed inclinometers. There are 16 base units, with a length of 2000mm and a width of 400mm. The channel steel is 100mm, as shown in Figure 1(a), and each inclinometer is rigidly connected to a horizontal strip steel plate with sufficient rigidity (referred to as the base). Each of the inclinometers is protected by two layers, as shown in Figure 1(b). between each base unit The hinged tubes are connected by hinges, and multiple bases are connected into a whole base, also known as a continuous settling plate, as shown in Figure 1(c). Starting from the place where no settlement occurs outside the dike, the entire foundation is buried between the dike and the seabed. When the dike causes the foundation to settle, as shown in Figure 2(a), the inclination angle θ meas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com