Circular disc shear blade space control method

A control method and technology of scissors, which are applied in the direction of electrical program control, program control in sequence/logic controller, shearing device, etc., can solve irregular blade spacing, inaccurate precision control, and strip yield Low-level problems, to achieve the effect of reducing strip burrs, high control precision, and improving the comprehensive yield of strip steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

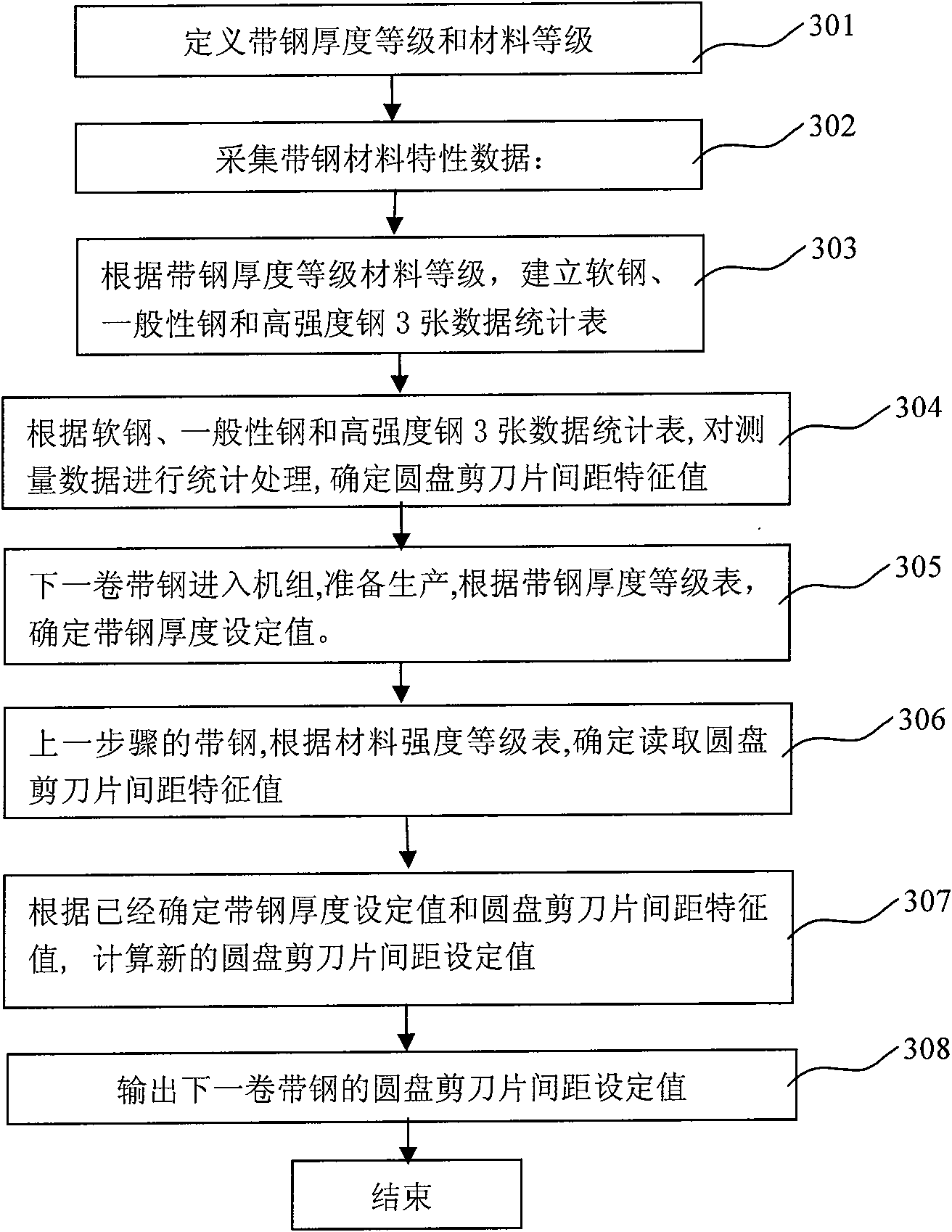

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0034] image 3 It is the flow chart of the disc scissors blade spacing control method of the present invention, as shown in the figure, step 301 is to divide the steel strip thickness grade and the material strength grade; The strip steel produced is divided into 9 strip steel thickness grades according to the thickness, and the Strip steel is divided into mild steel (tensile strength 200-300 MPa), general steel (tensile strength 300-340 MPa) and high-strength steel (tensile strength 340-450 MPa) according to material strength. 3 material strength levels. The strip thickness grade table and material strength grade table shown in Table 2 and Table 3.

[0035] Table 2: Strip Thickness Grade Table

[0036]

[0037]

[0038] Table 3: Material strength grade table

[0039] Material strength (MPa)

Material strength grade

200≤P<300

mild s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com