Axial movement control method for continuously variable crown (CVC) working roll

A technology of axial movement and control method, applied in contour control, electrical program control, program control in sequence/logic controller, etc., can solve the problem that the axial movement position of the work roll cannot smoothly transition to the next strip target work roll Axial moving position, large changes in production strip material, etc., to achieve the effect of high target control accuracy, easy operation and strong productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

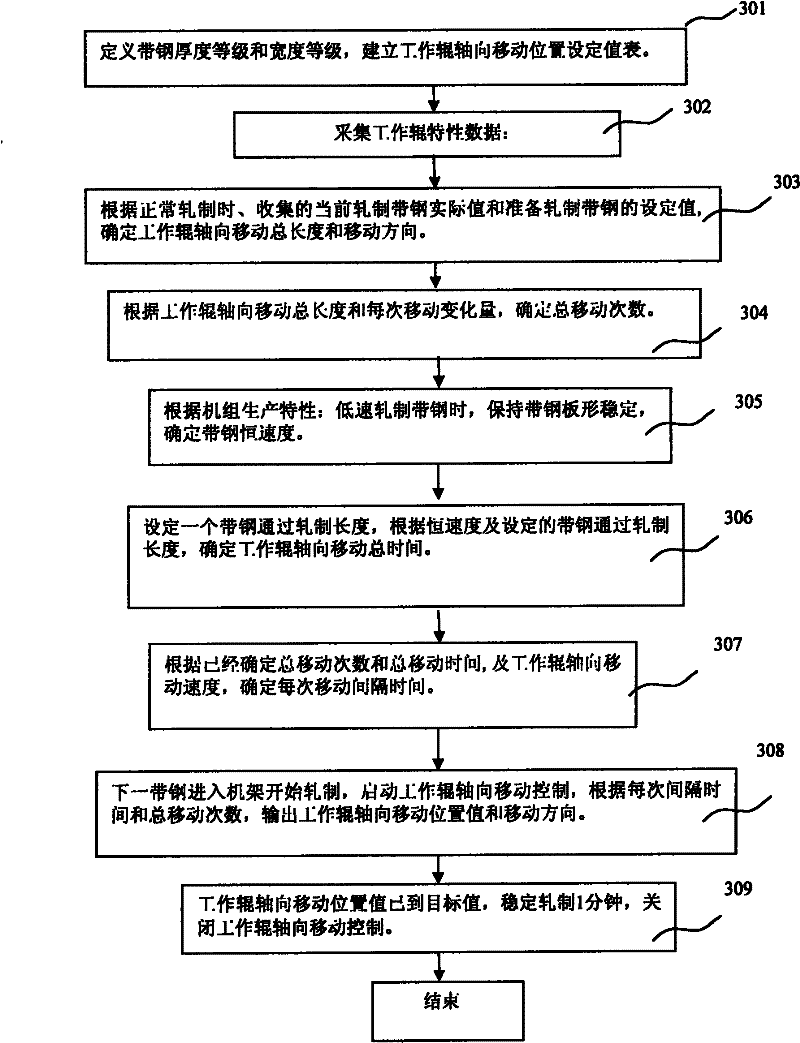

[0044] Step 301, define (divide) strip thickness grades and strip width grades, and establish a work roll axial movement position setting value table. Table 2 is an embodiment of the work roll axial movement position set value table.

[0045] Table 2: Table of setting value of work roll axial movement position

[0046]

[0047] In this embodiment, the strip steel thickness grade and width grade are divided, the strip steel width is divided into 5 grades, and the strip steel thickness is divided into 5 grades, and the setting value of the axial movement position of the work roll is determined through the corresponding relationship between the thickness grade and the width grade Relational tables.

[0048] Step 302, collecting work roll characteristic data, including the actual value of the currently rolled strip and the set value of the ready-to-roll strip, wherein: the current actual value of the rolled strip includes: steel coil number, product type, finished strip Steel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com