Bearing fault self-diagnosis method and apparatus

A self-diagnosis and bearing technology, applied in signal transmission systems, instruments, etc., can solve problems such as misdiagnosis or missed diagnosis, low signal-to-noise ratio of fault characteristic signals, and unsatisfactory diagnosis results, so as to reduce human dependence and improve autonomy. performance, and the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

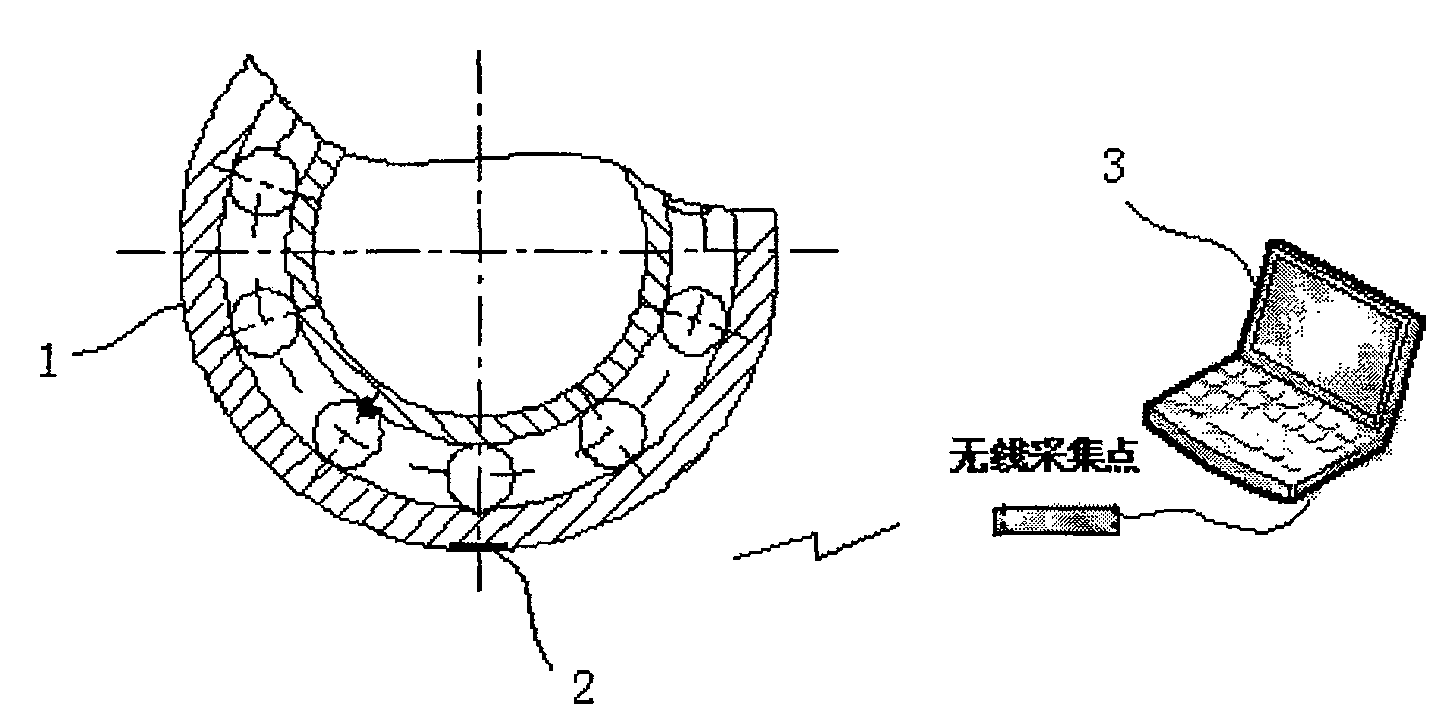

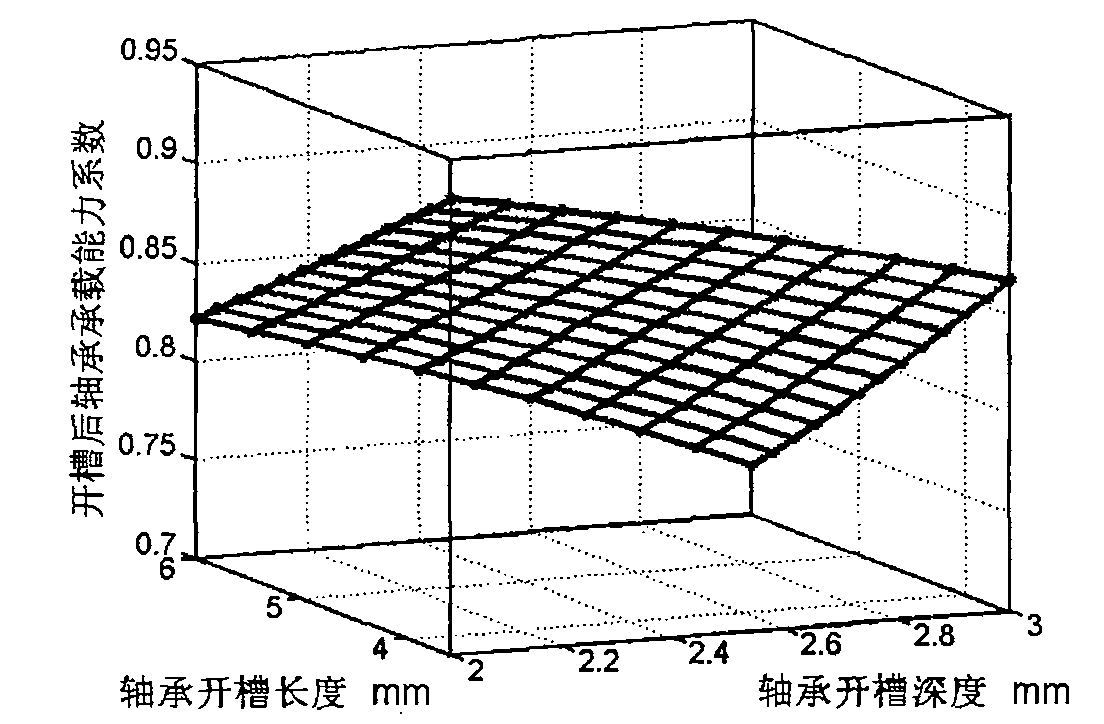

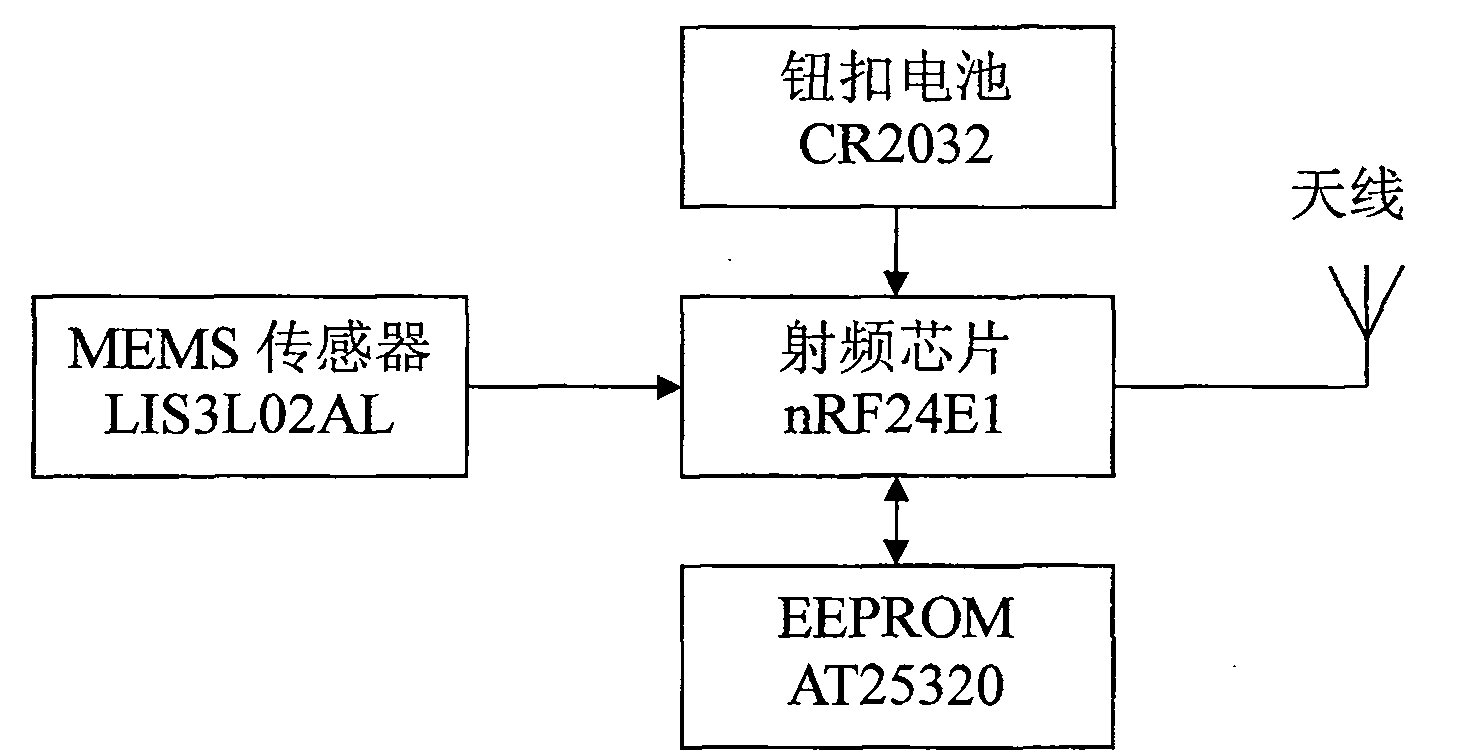

[0092] Taking deep groove ball bearing 6220 as an example, the slotting position is selected on the outer ring of the bearing. Take the external load as F r =50kN, at this time the bearing works in the elastic range. Calculate the maximum load Q on the raceway of the outer ring according to formula (2) max = 25kN; according to the formula (3), the size of the elliptical area carried by the outer ring raceway is a = 5.525mm, b = 0.7482mm; when the bearing capacity coefficient is 0.8, the width of the small groove is 6mm and the length is 34mm ( Equal to the thickness of the bearing), the depth is 3mm. Then, the wireless vibration microsensor integrated with self-diagnosis algorithm is embedded in the small groove, and the remote monitoring PC is used to monitor the wireless vibration microsensor to diagnose the running state of the bearing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com