Preparation method and application of a material supplemented active carbon containing natural extract

A technology of activated carbon and plants, applied in the fields of application, food science, tobacco, etc., can solve the problems affecting the smoking quality of cigarettes, achieve the effects of improving smoking quality, wide distribution, and compensating the taste of tobacco

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

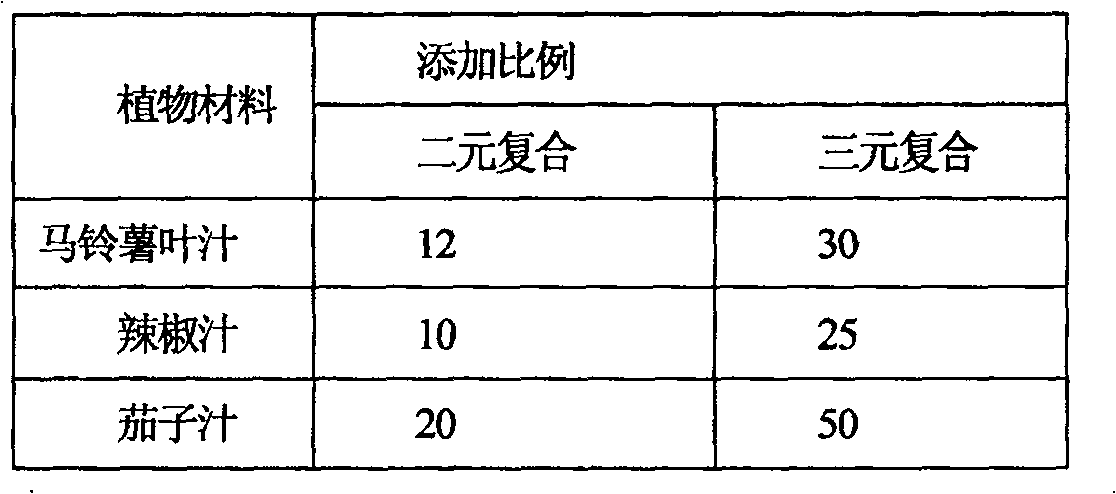

Method used

Image

Examples

Example Embodiment

[0012] Embodiment 1: select the plant fruit that tobacco has kinship relationship---tomato as raw material, select tomato, remove the tomatoes that do not meet the requirements such as spoilage, damage, etc., clean the selected material, remove the dirt on the selected material , to make the selected material purer. Use natural drying or directly use an oven to dry the surface moisture of tomatoes at room temperature 40 ℃, so as to avoid the influence of moisture on the quality of the selected materials. Use a juicer to make the tomatoes into juice, and then filter to remove impurities. After accurate weighing, add activated carbon in a ratio of 1:1, seal and refrigerate for 12 hours, so that the activated carbon can fully absorb the active ingredients of the tomato liquid. Dry in an oven at room temperature of 30-40°C, control the moisture content at 10-12%, grind and sieve with a 40-60 mesh sieve to ensure the particle size of the activated carbon, and finally obtain the act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com