Driving control apparatus

A technology for driving transmission and control signals, applied in printing devices, control using feedback, printing, etc., can solve problems such as slow response speed and large speed control error, and achieve the goal of reducing speed error, increasing stability, and speeding up response speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

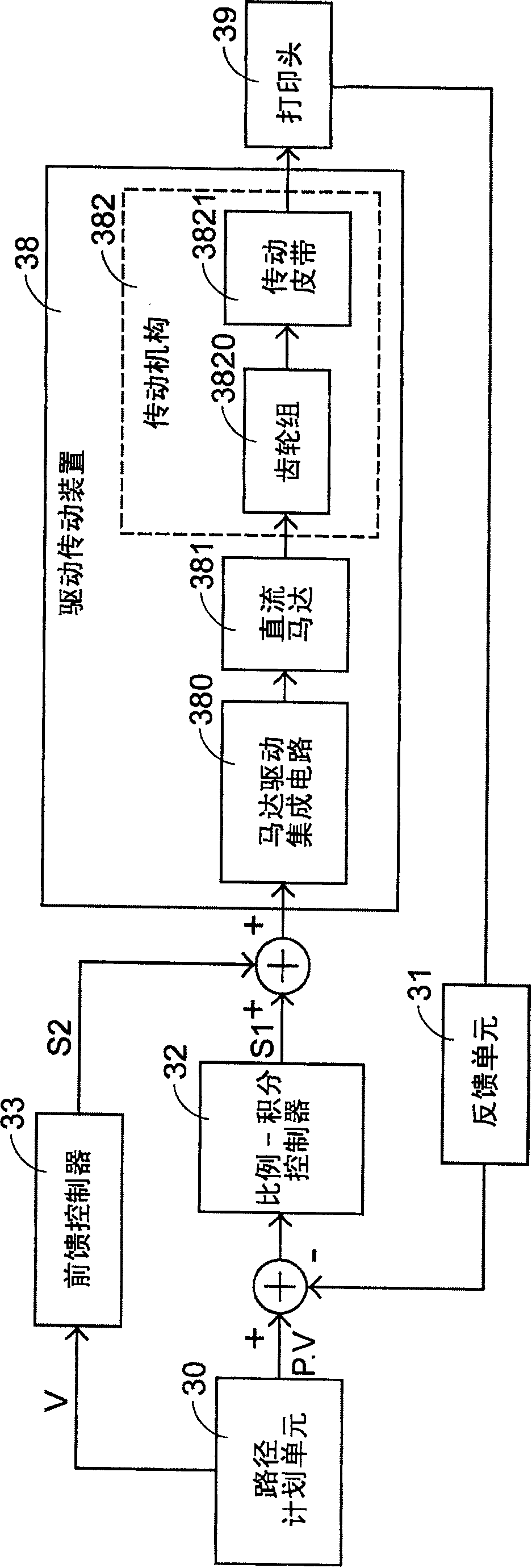

[0026] See image 3 , which is a functional block diagram of a preferred embodiment of an inkjet head driving control device that can improve the defects of the present invention and can be applied to an inkjet printer or an inkjet multifunction machine, which mainly includes a path planning unit 30 , a feedback unit 31, a proportional-integral controller 32 and a feedforward controller 33, wherein the path planning unit 30 is the same as the prior art, and it is used to output a position command value P and a speed command value V, and the feedback unit 31 is mainly based on The actual position and speed of the print head 39 generate a position feedback signal Pf and a speed feedback signal Vf, and the proportional-integral controller 32 is based on the difference Pd between the position command value P and the position feedback signal Pf and the speed command value V and The difference Vd of the speed feedback signal Vf generates the first control signal S1. The feed-forwar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com