Repair method of box-shaped apron wheel mechanism

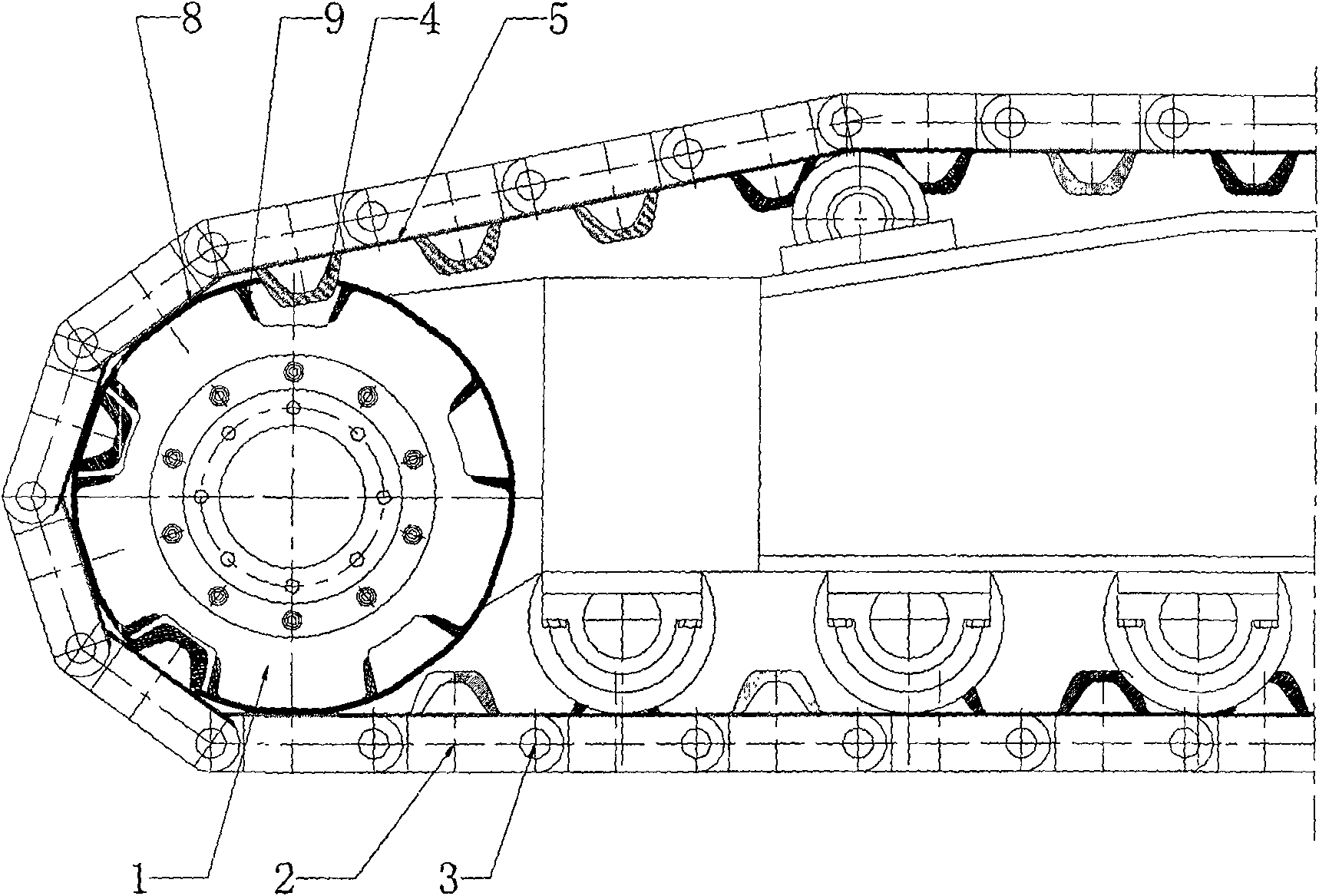

A crawler mechanism and repair method technology, which is applied to arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of difficult to achieve meshing relationship, difficult repair, interference and gnawing teeth, etc., to reduce maintenance costs and restore work performance , good wear resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The repair method of box crawler mechanism, it comprises the steps:

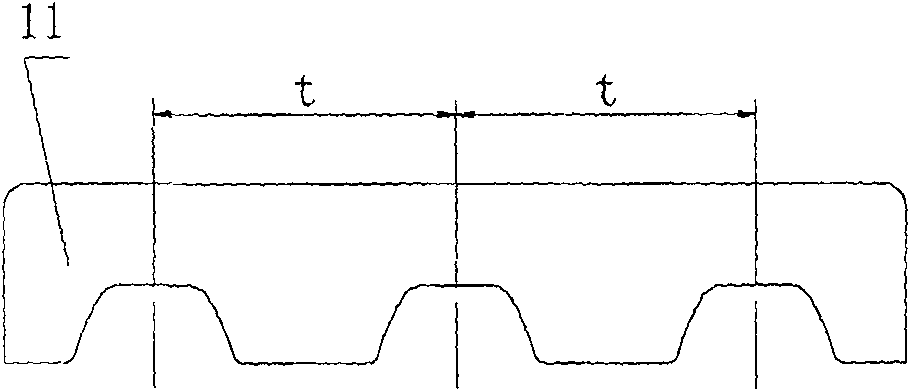

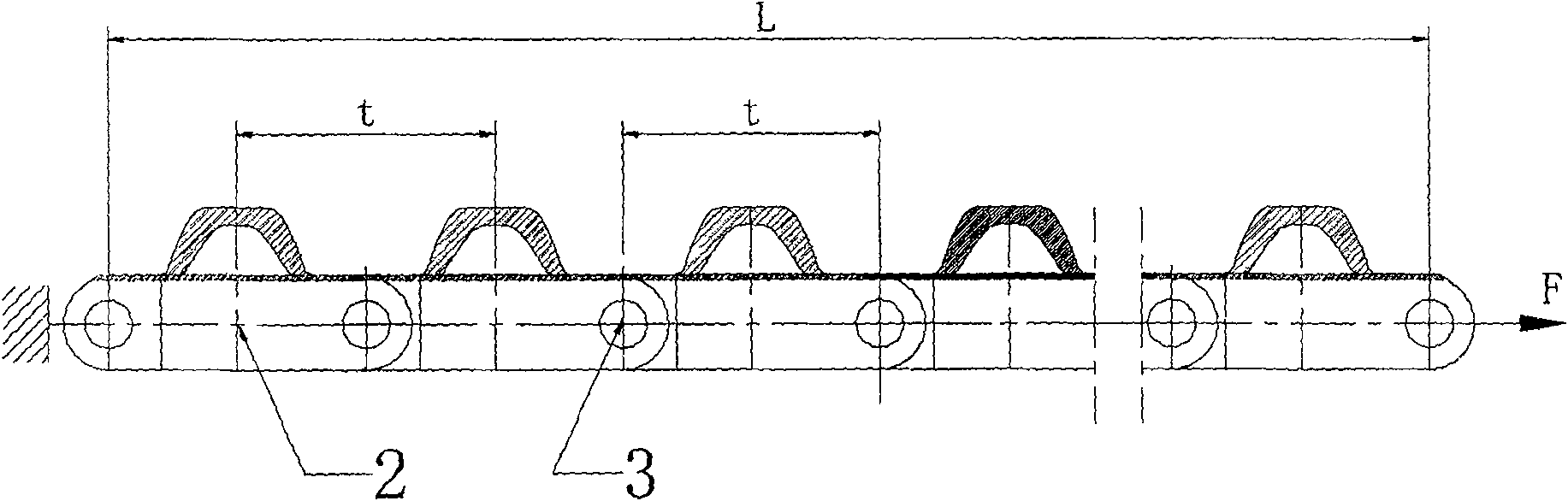

[0029] 1) Measure the actual combined average pitch t of the worn track shoes and track pins; spread the track shoes 2 on a flat ground, fix one end, and apply a force F to the other end (a chain block can be used) to eliminate the track The gap between the lug holes and the track pins; measure the center distance from the adjacent track pins of the track shoes connected together to the track pins, and calculate the average pitch, which is the actual combined average pitch of the worn track shoes and track pins distance t; image 3 shown;

[0030] 2) Measure the actual center height h between the worn track shoe tread and the ear hole (such as Figure 4 shown);

[0031] 3) Calculate the radius R of the contact surface on the outer edge of the driving wheel,

[0032] R = t / 2 tan ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com