Argon recovery and purification device and purification method thereof

A technology of argon gas and vents, which is applied in the purification/separation of inert gases, chemical instruments and methods, inert gas compounds, etc., and can solve the problems of difficult intelligent switching of working groups and affecting purification efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

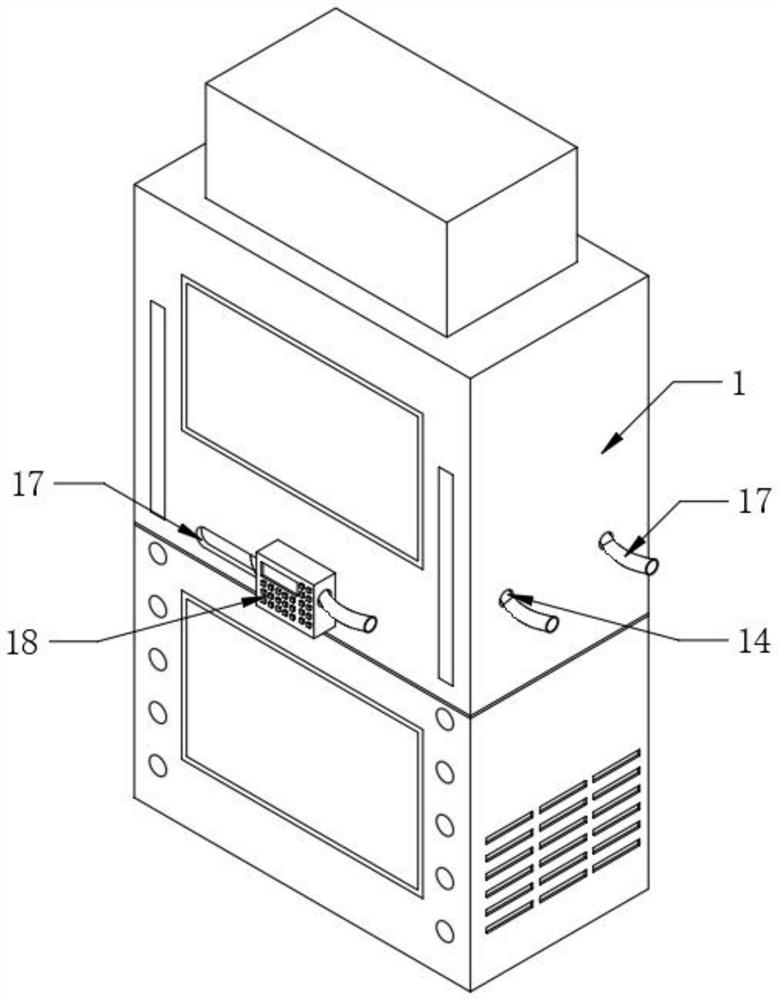

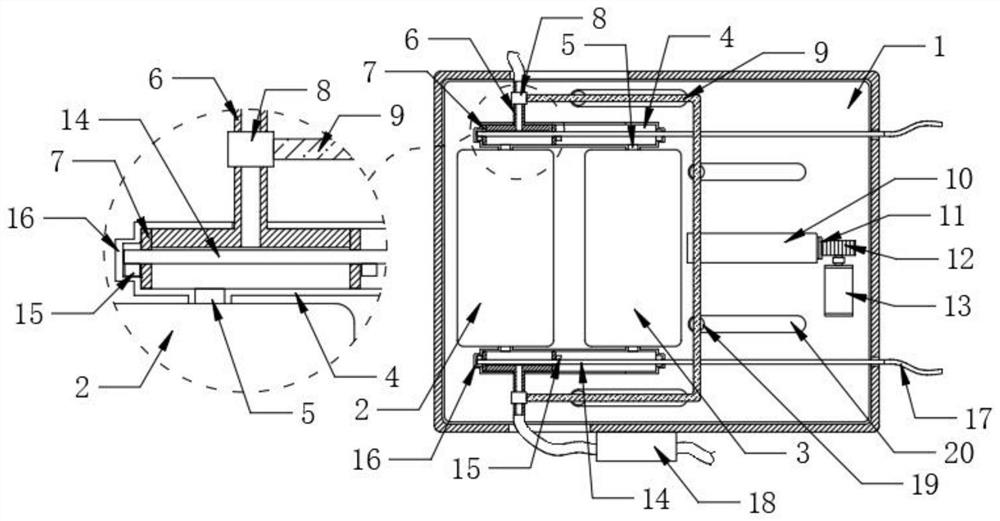

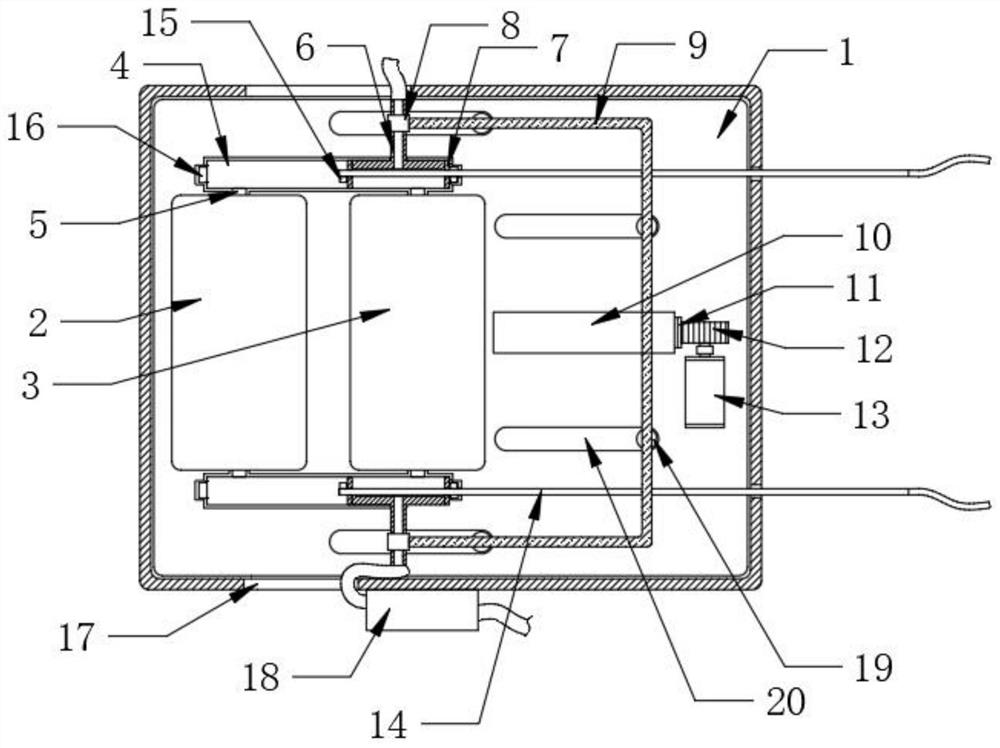

[0024] Such as Figure 1-3 As shown, the present invention proposes an argon gas recovery and purification device and its purification method, comprising a device main body 1, a first working group 2 and a second working group 3 are arranged in the device main body 1, and a pair of Argon gas shunt pipe 4, and two argon gas shunt pipes 4 are respectively located at the two ends of the first working group 2 and the second working group 3, and a single argon gas shunt pipe 4 is provided with a pair of vents 5, two vents 5 communicate with the first working group 2 and the second working group 3 respectively, and a shunt valve tube 6 can be slidably connected to the two argon gas shunt pipes 4, and the shunt valve pipe 6 includes a horizontal part and a vertical part, wherein the horizontal part It is located in the argon gas shunt pipe 4, and the two ends of the horizontal part are fixedly connected with the sealing sheet 7 at the corresponding position, and the vertical part is ...

Embodiment 2

[0027] Such as Figure 1-3 As shown, the present invention proposes an argon gas recovery and purification device and its purification method, comprising a device main body 1, a first working group 2 and a second working group 3 are arranged in the device main body 1, and a pair of Argon gas shunt pipe 4, and two argon gas shunt pipes 4 are respectively located at the two ends of the first working group 2 and the second working group 3, and a single argon gas shunt pipe 4 is provided with a pair of vents 5, two vents 5 communicate with the first working group 2 and the second working group 3 respectively, and a shunt valve tube 6 can be slidably connected to the two argon gas shunt pipes 4, and the shunt valve pipe 6 includes a horizontal part and a vertical part, wherein the horizontal part It is located in the argon gas shunt pipe 4, and the two ends of the horizontal part are fixedly connected with the sealing sheet 7 at the corresponding position, and the vertical part is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com