Method for preparing highly water-soluble cydiodine

A cedidin, water-soluble technology, applied in the directions of active ingredients of iodine compounds, non-active ingredients of polymer compounds, drug combinations, etc., can solve the problems of long process, unsuitable for environmental disinfection, unsuitable for large-scale environmental disinfection and use, etc. To achieve the effect of fast coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

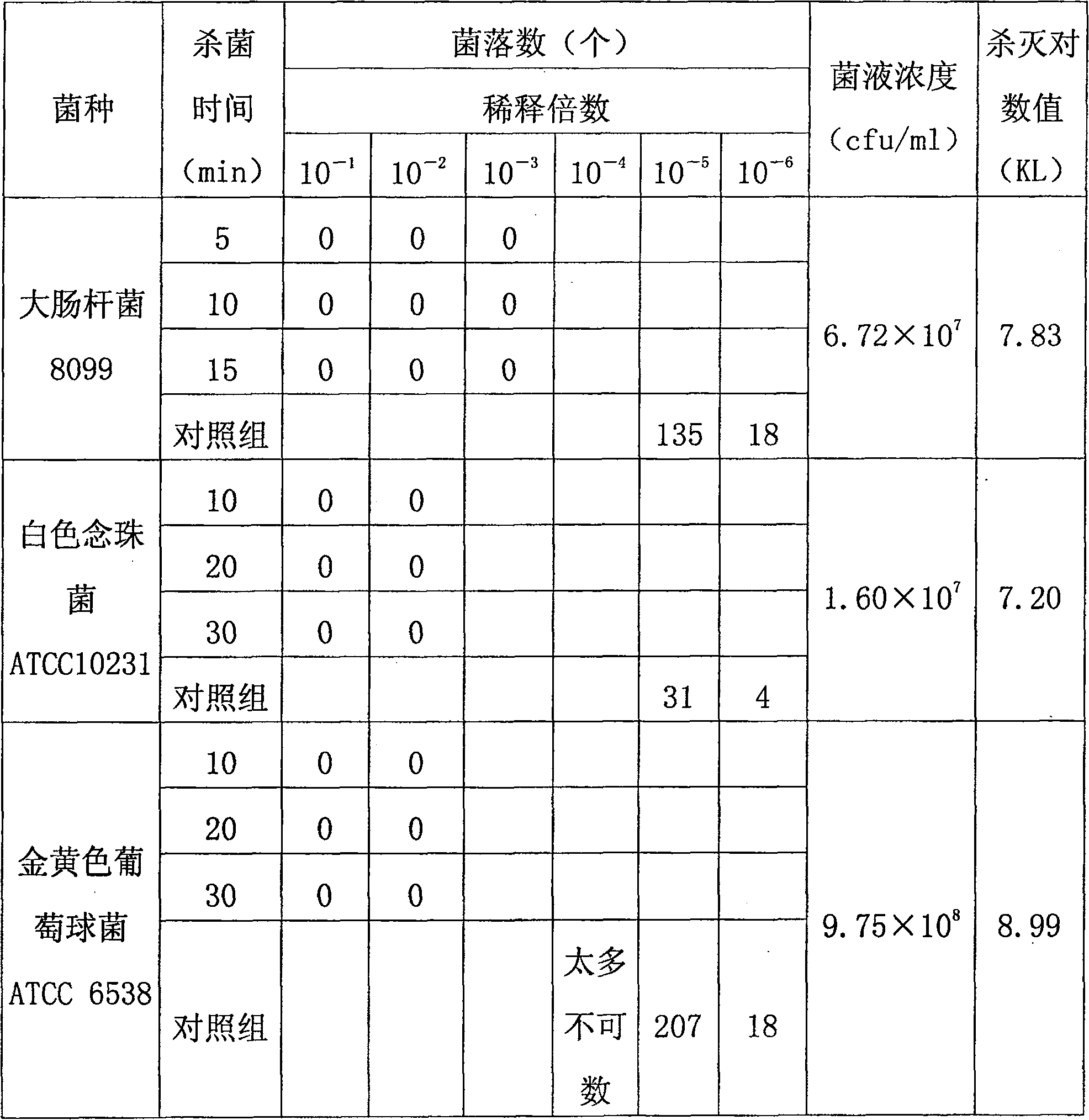

Examples

example 1

[0038] Weigh 300g of β-cyclodextrin, add it into a glass reaction kettle with 1000ml of water, stir and heat it to 88°C-90°C and dissolve completely, then keep the temperature for later use. Weigh 67.1g of iodine and 5g of KI, add them to 200ml of 90% ethanol solution, and heat to 60°C to dissolve them all. Then, under stirring, the iodine solution was quickly added to the saturated solution of β-cyclodextrin, then the heating was stopped, and the reaction kettle was naturally cooled to 30°C under constant stirring. Then pour the reaction solution into a beaker and store it at room temperature for 24 hours to allow the cediiodine to precipitate naturally, then remove the supernatant, then put the precipitate in an enamel plate, and put it in an oven at 55°C to dry-bake until powdered. After sieving the powder, put it into an enamel plate and spread it evenly, then put it in the oven, raise the temperature of the oven to 120°C and maintain it for 40 minutes, mix the dry-baked c...

example 2

[0040] Weigh 200g of β-cyclodextrin, add it into a glass reaction kettle with 1000ml of water, stir and heat to 70°C to 72°C and dissolve completely, then keep the temperature for later use. Weigh 44.7g of iodine and 6g of KI, add them to 300ml of 95% ethanol solution, and heat to 50°C to dissolve them all. Under stirring, the iodine solution was quickly added to the β-cyclodextrin saturated solution, and then the heating was stopped, and the reaction kettle was naturally cooled to 35°C under constant stirring. After centrifuging the reaction solution with a continuous high-speed centrifuge with a rotation speed of 15000rps, the precipitate obtained by centrifugation was placed in an enamel plate, and put into an oven at 50°C to dry-bake until powdered. After sieving the powder, put it into an enamel plate and spread it evenly, then put it into the oven, raise the temperature of the oven to 130°C and maintain it for 30 minutes, mix the dry-baked cedi iodine evenly, and you can...

example 3

[0042] Weigh 500g of β-cyclodextrin, add it into a glass reaction kettle with 1500ml of water, stir and heat it to 80°C-82°C and dissolve completely, then keep the temperature for later use. Weigh 111.8g of iodine and 15g of KI, add them to 350ml of 80% ethanol solution, and heat to 60°C to dissolve them all. Under stirring, the iodine solution was quickly added to the β-cyclodextrin saturated solution, then the heating was stopped, and the reaction kettle was naturally cooled to 30°C under constant stirring. Then the reaction solution is spray-dried, the hot air temperature of the spray dryer is set at 160° C., the material outlet temperature is 70° C., and the cediodine is once spray-dried into powder. Put the cediodine into the enamel plate and spread it evenly, then put it into the oven, raise the temperature of the oven to 140°C and keep it for 15 minutes, and mix the dry-baked cediiodine evenly.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap