Abrasion-proof arrangement

A technology of wear-resistant blocks and wear-resistant parts, which is applied in the wear-resistant field, can solve the problems of large frictional resistance of the wear-resistant surface, affecting the opening and closing of the mold, and the repeated sliding of the slider is not smooth enough, so as to achieve sensitive sliding and reduce contact friction. Resistance, the effect of reducing contact frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

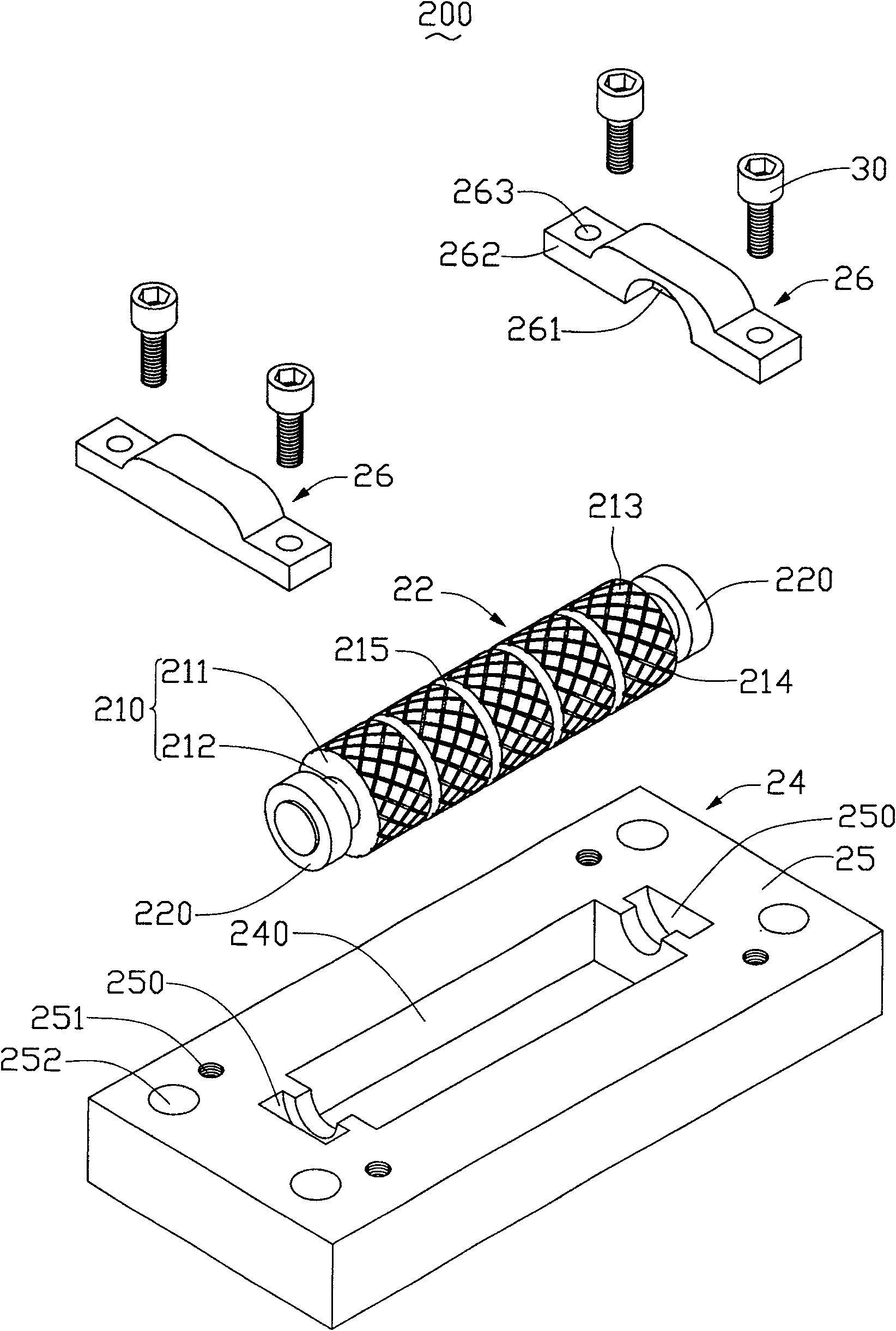

[0014] refer to image 3 and Figure 4 , the wear-resistant device 200 provided by Embodiment 1 includes a wear-resistant piece 22 , a base 24 and two fixing pieces 26 .

[0015] The wear member 22 includes a rotating portion 210 and two fixing portions 220 .

[0016] The rotating part 210 includes a wear-resistant block 211 and a rotating shaft 212 . The wear-resistant block 211 is a cylindrical structure and sleeved on the rotating shaft 212 . The rotating shaft 212 is rotatable. The inner diameter of the cylinder of the wear-resistant block 211 matches the rotating shaft 212 so as to be sleeved on the rotating shaft 212 . When the inner diameter of the cylinder of the wear block 211 is greater than the diameter of the rotating shaft 212, the wear block 211 sleeved on the rotating shaft 212 can rotate on the rotating shaft 212, and it can also be driven by the rotation of the rotating shaft 212 to rotate; when the wear block When the inner diameter of the barrel of 211 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com