socket

A technology of sockets and plugs, which is applied in the direction of the base/housing, coupling devices, electrical components, etc., can solve the problems of unsatisfactory automatic assembly, complicated socket assembly process, and many components, and achieve the convenience of automatic assembly, stable and reliable fixed structure, and process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

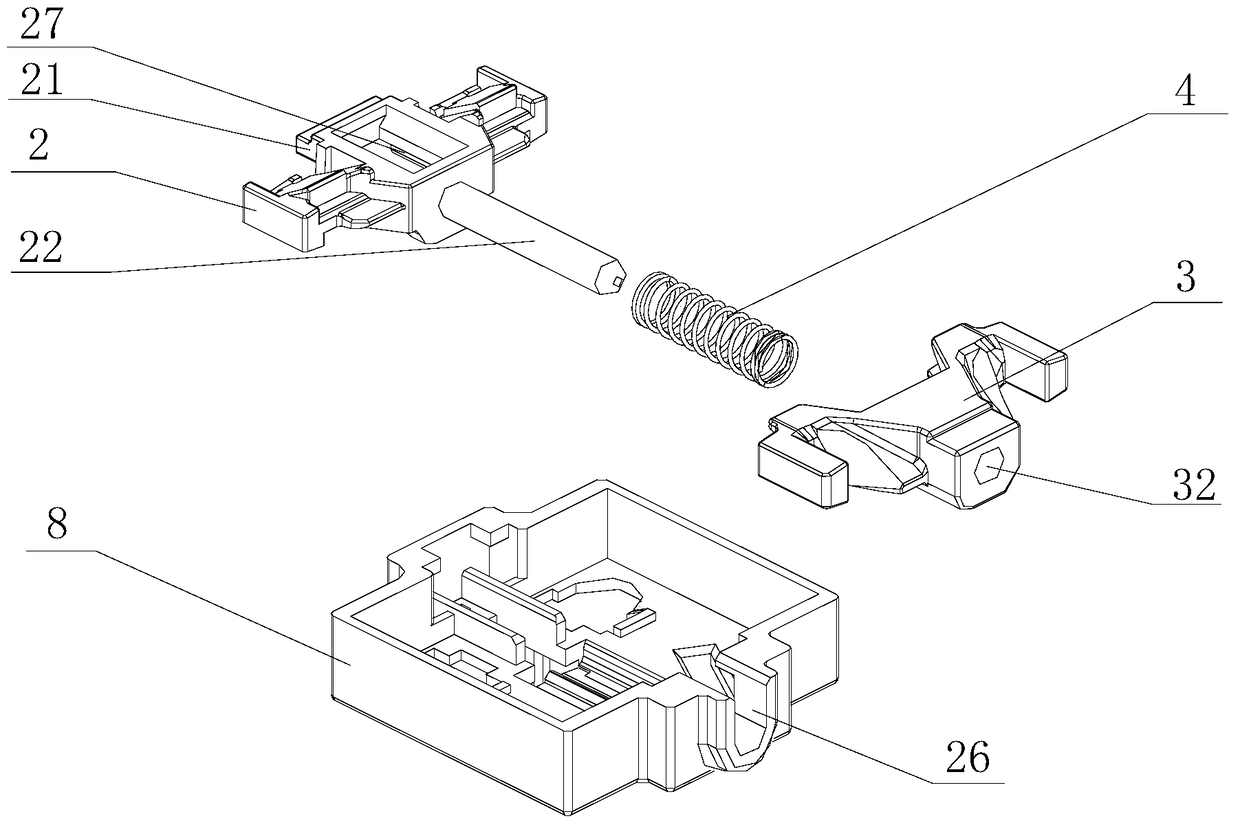

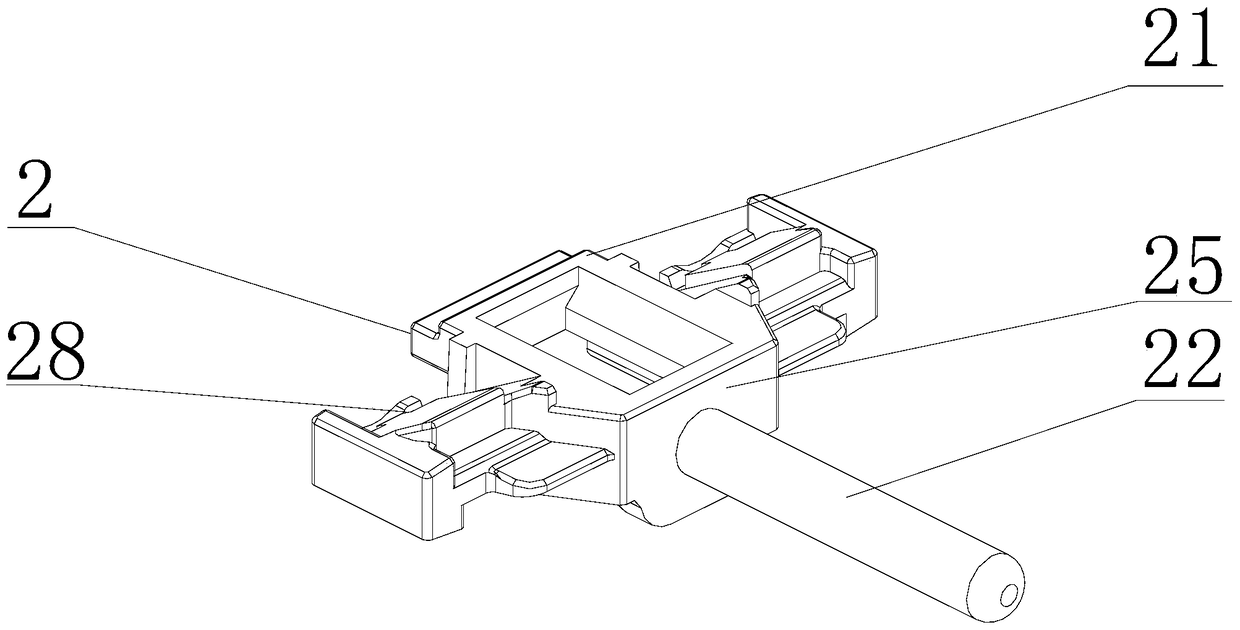

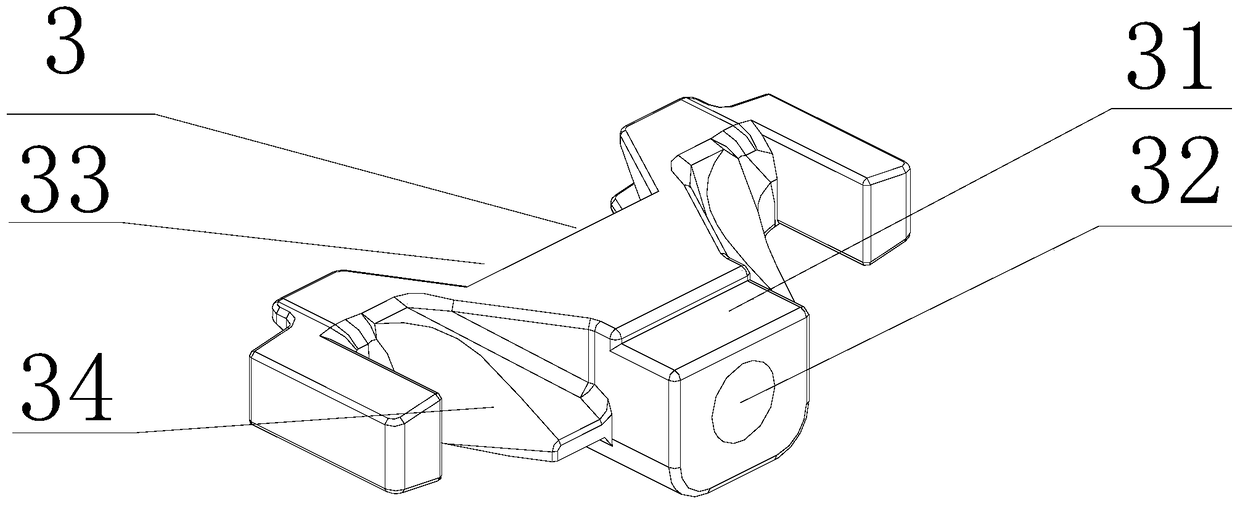

[0026] The following is attached Figures 1 to 10 The given examples further illustrate the specific implementation of the socket of the present invention. The socket of the present invention is not limited to the description of the following embodiments.

[0027] like figure 1 As shown, the socket of the present invention includes an independent pressure plate 1, a protective door placed above the pressure plate 1 and a socket sleeve placed below the pressure plate 1. When the plug is inserted, the protective door moves and opens, so that the plug is inserted into the socket below the pressure plate 1. It includes two protective doors, and there is an installation and fixing structure between the two protective doors, and there is a limit structure on the pressure plate 1, and the two protective doors are provided with a limit part corresponding to the limit structure; when installing, the two The protective doors are installed together into the pressure plate 1 through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com