Gravity sensor

A technology of gravity sensor and weight-reducing groove, applied in the field of sensors, can solve the problems of complex structure, low service life, insensitive response, etc., and achieve the effects of simple overall structure, guaranteeing elasticity, and improving detection accuracy and sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

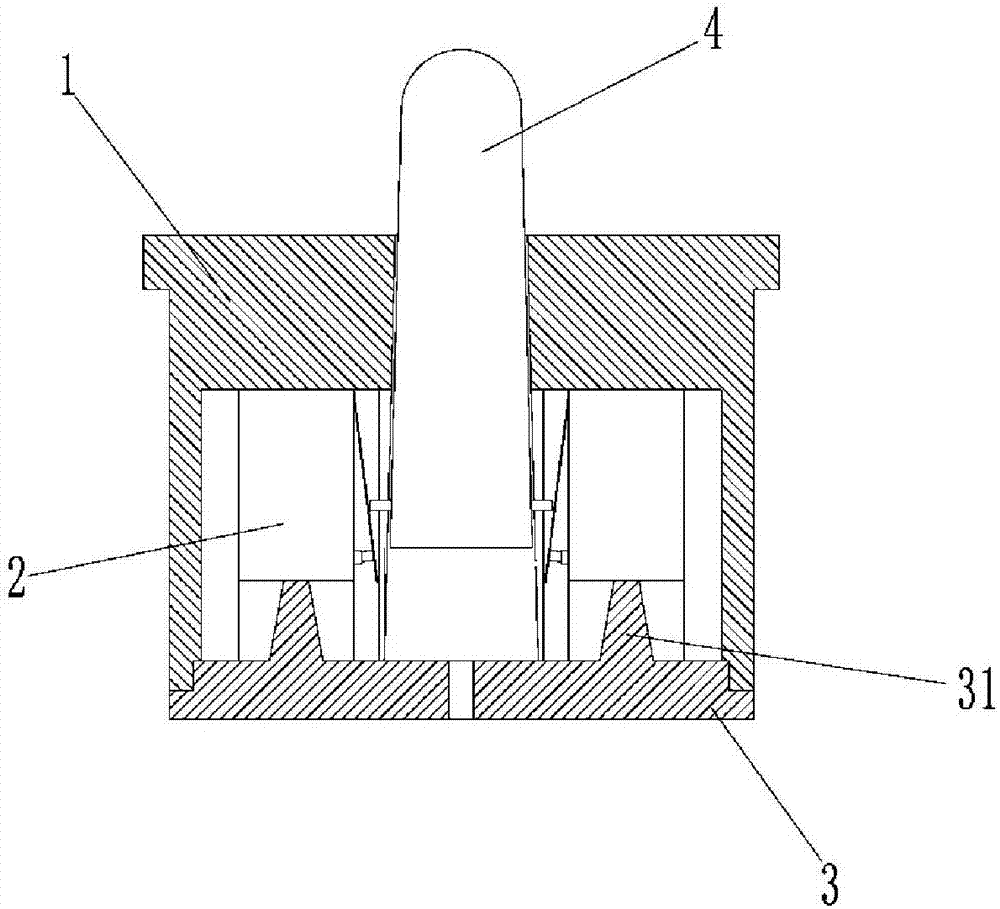

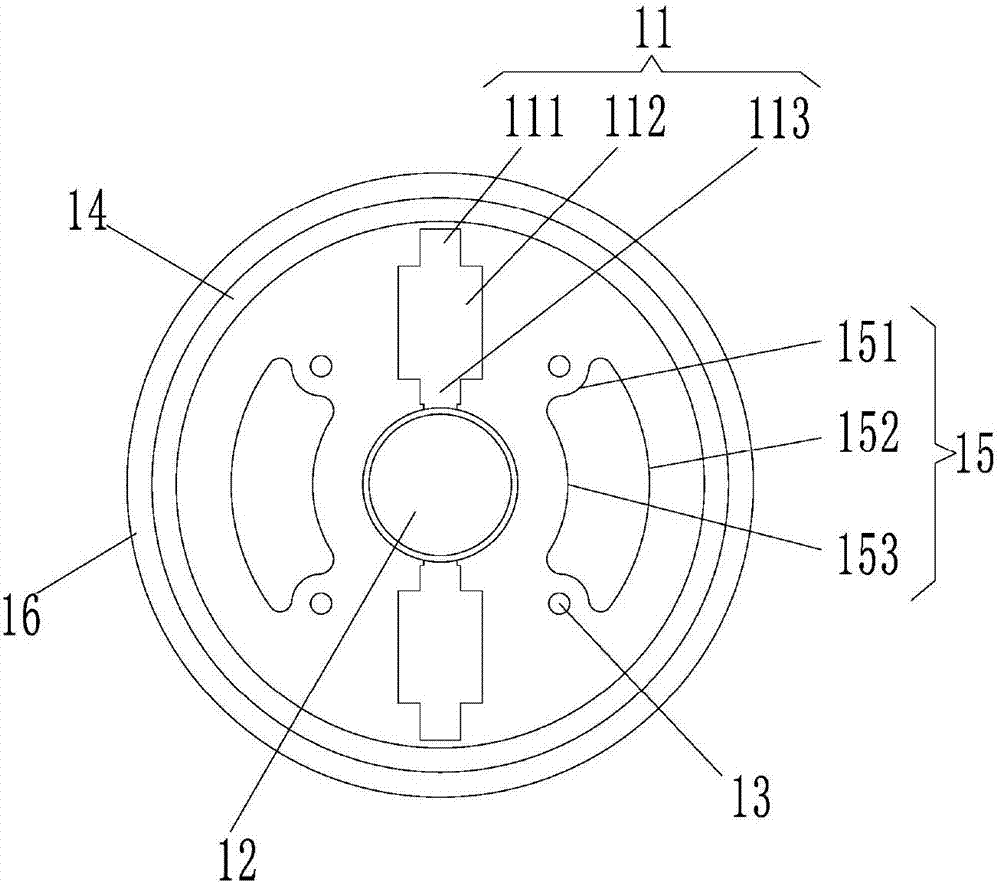

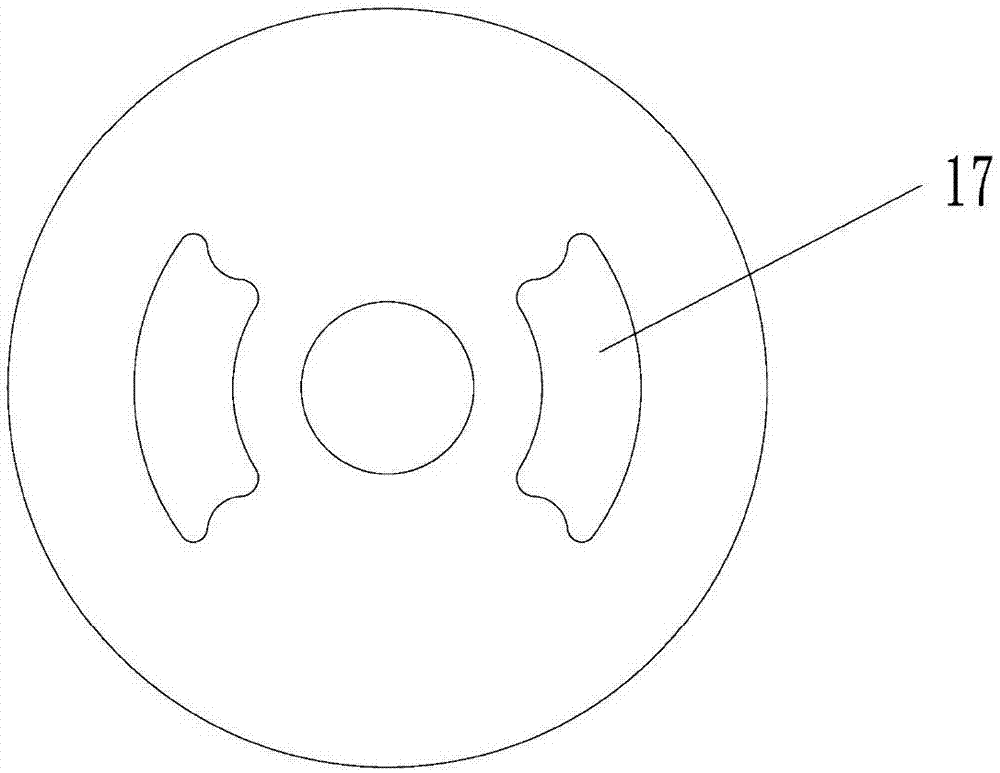

[0014] Such as Figure 1 ~ Figure 2 As shown, a gravity sensor according to the present invention includes a housing 1 and a bottom cover 3 matched with the housing 1. A symmetrical installation groove 11 is opened on the upper surface of the housing 1. The installation groove 11 It includes cable trough 111, switch receiving trough 112 and guide chute 113 connected in sequence, and the width of switch receiving trough 112 is greater than the width of cable trough 111 and guide chute 113, and a rounded structure is provided on the transition edge to avoid Disadvantages caused by processing burrs. A micro switch 2 is placed in the switch receiving groove 112, and the shrapnel of the micro switch 2 obliquely passes through the guide chute 113, and the connecting terminal of the micro switch 2 is located in the cable groove 111; There are two symmetrical protruding post...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com