Peg for stringed instrument

一种卷线装置、弦乐器的技术,应用在弦乐器、乐器、仪器等方向,能够解决卷取轴旋转摩擦阻力变大、部件磨损等问题,达到防止接触、防止迅速磨损的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

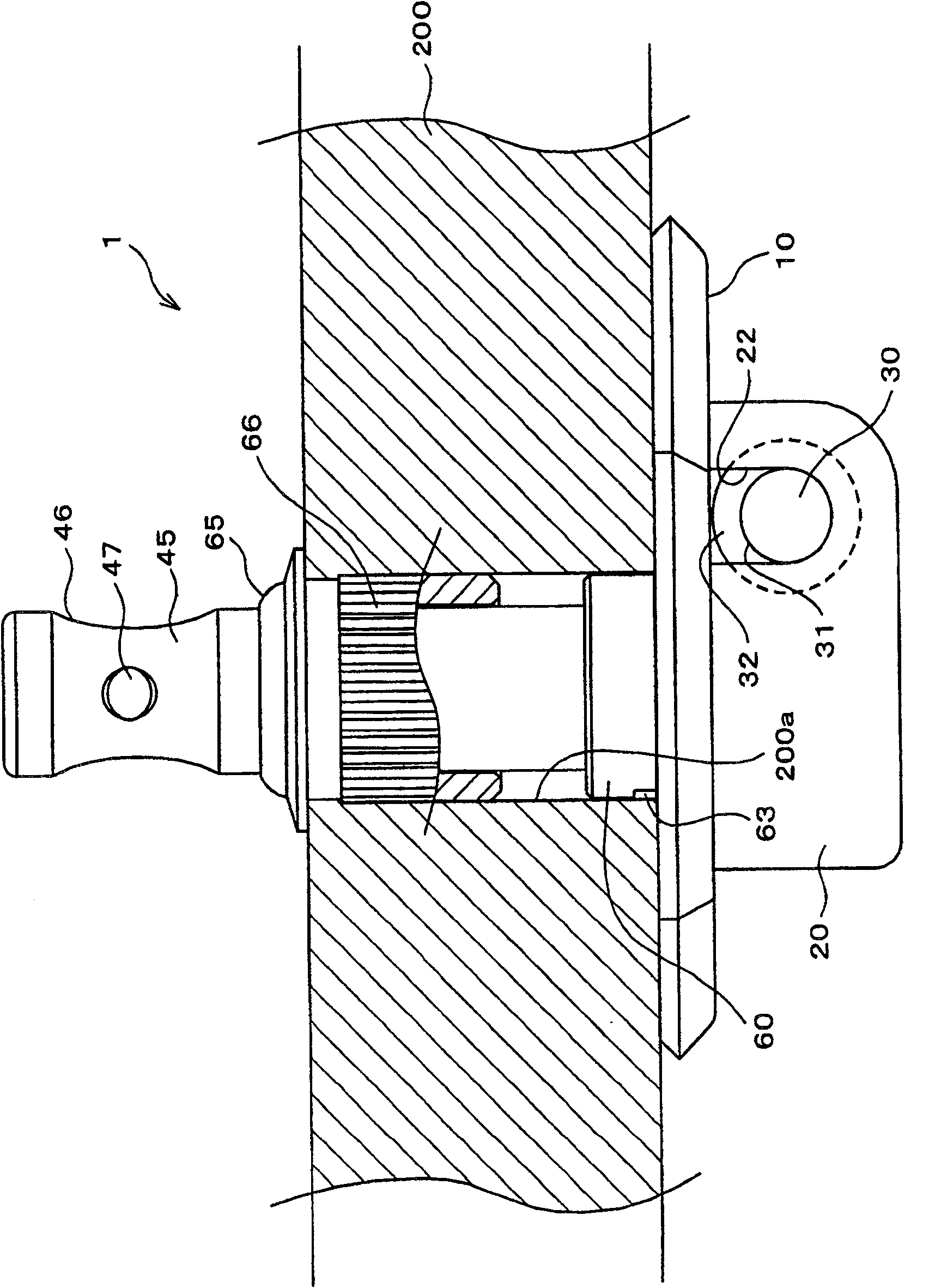

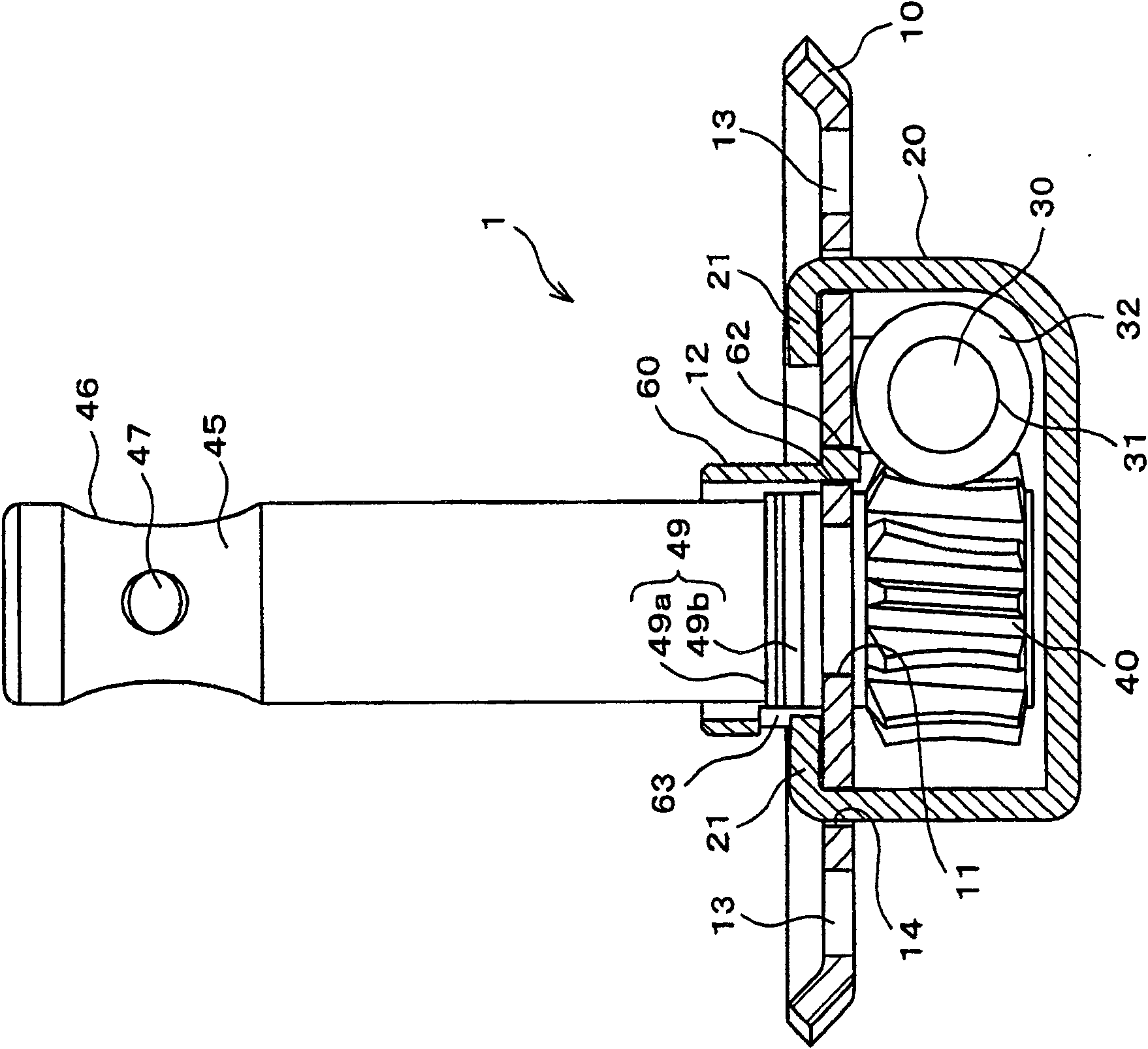

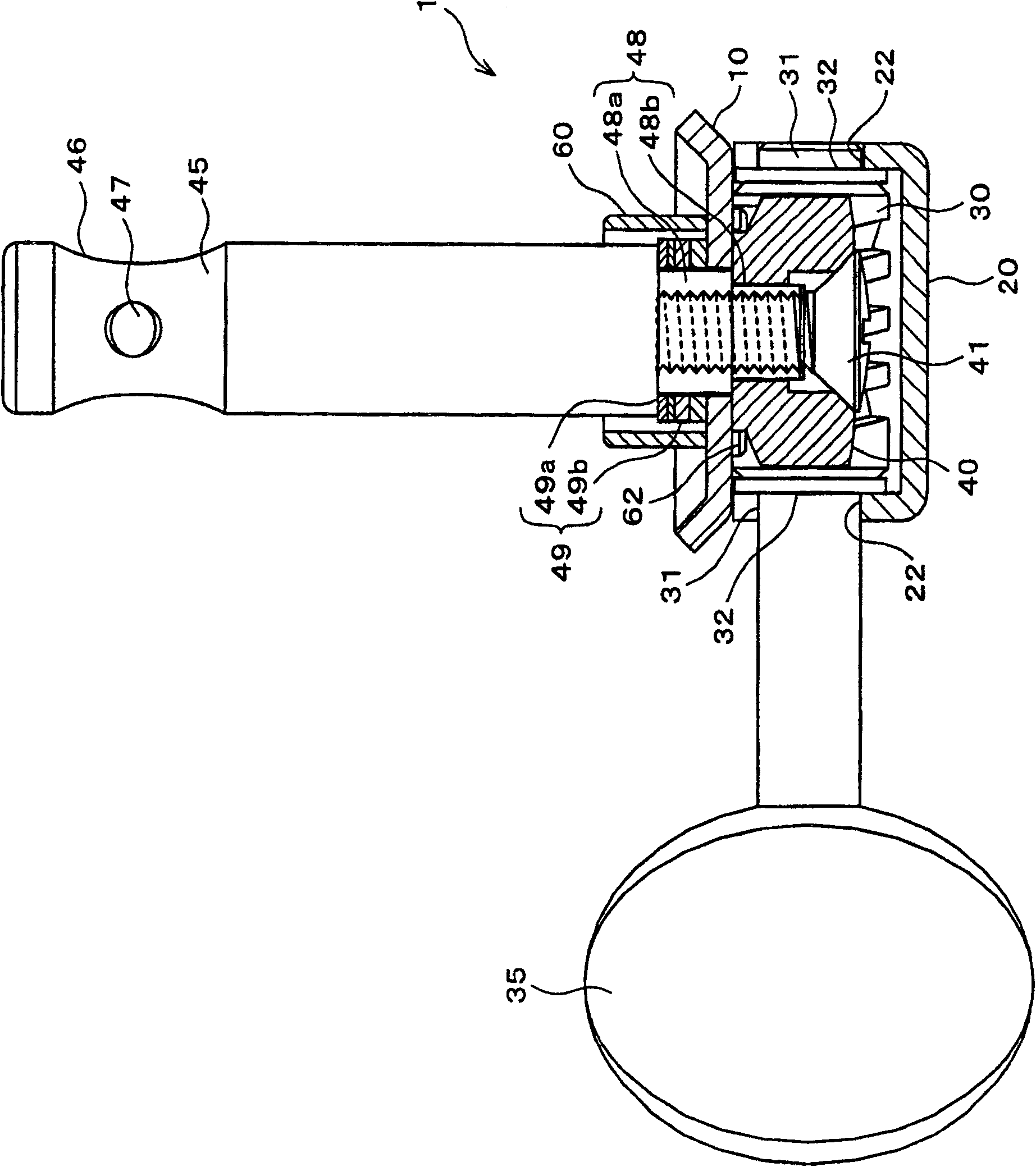

[0026] refer to Figure 1 ~ Figure 5D A first embodiment of the present invention will be described. Figure 1 ~ Figure 3 Showing the schematic structure of the wire winding device 1 according to the first embodiment of the present invention, figure 1 It is a side view of a state in which the cord winding device 1 is mounted on the head 200 of a stringed instrument viewed from the side of the head 200, figure 2 is its cross-sectional view, image 3 With figure 2 Orthogonal cutaway view. First, the outline of the overall configuration of the wire winding device 1 will be described. Reference numeral 10 in the figure is the main body of the cord winding device 1, and reference numeral 20 is the cover body. A worm 30 is rotatably supported between the cover 20 and the main body 10 . On the worm 30, a knob 35 for rotating it is installed (refer to image 3 ). In addition, a worm wheel 40 meshes with the worm 30 . A take-up shaft 45 penetrates through the hole 200 a of ...

no. 2 approach

[0038] refer to Figure 6 ~ Figure 10C A second embodiment of the present invention will be described. The second embodiment is different from the first embodiment in that only the main body of the cord winding device constitutes the bearing of the worm without using a cover. Therefore, in the following description, the same reference numerals are attached to the same components as those of the first embodiment, and description thereof will be omitted.

[0039] Reference numeral 70 in the figure represents the main body of the winding device 2, Figure 10A ~ Figure 10C Its detailed structure is shown in . The main body 10 is formed by press-forming a metal plate such as a steel plate, and has a support hole 71 formed in its central portion, and the lower end portion of the winding shaft 45 is rotatably supported by the support hole 71 . Around the support hole 71, a plurality of (three in this embodiment) insertion holes 72 are formed at equal intervals in the circumferenti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com