Stereoscopic garage system

A technology of three-dimensional garages and garages, applied in the field of garages, can solve the problems of parking density, access speed, convenient parking, poor consideration of construction and maintenance costs, complex design of carriers, lack of good balance points, etc., to achieve construction and maintenance costs Low cost, low construction and operation costs, and improved parking convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

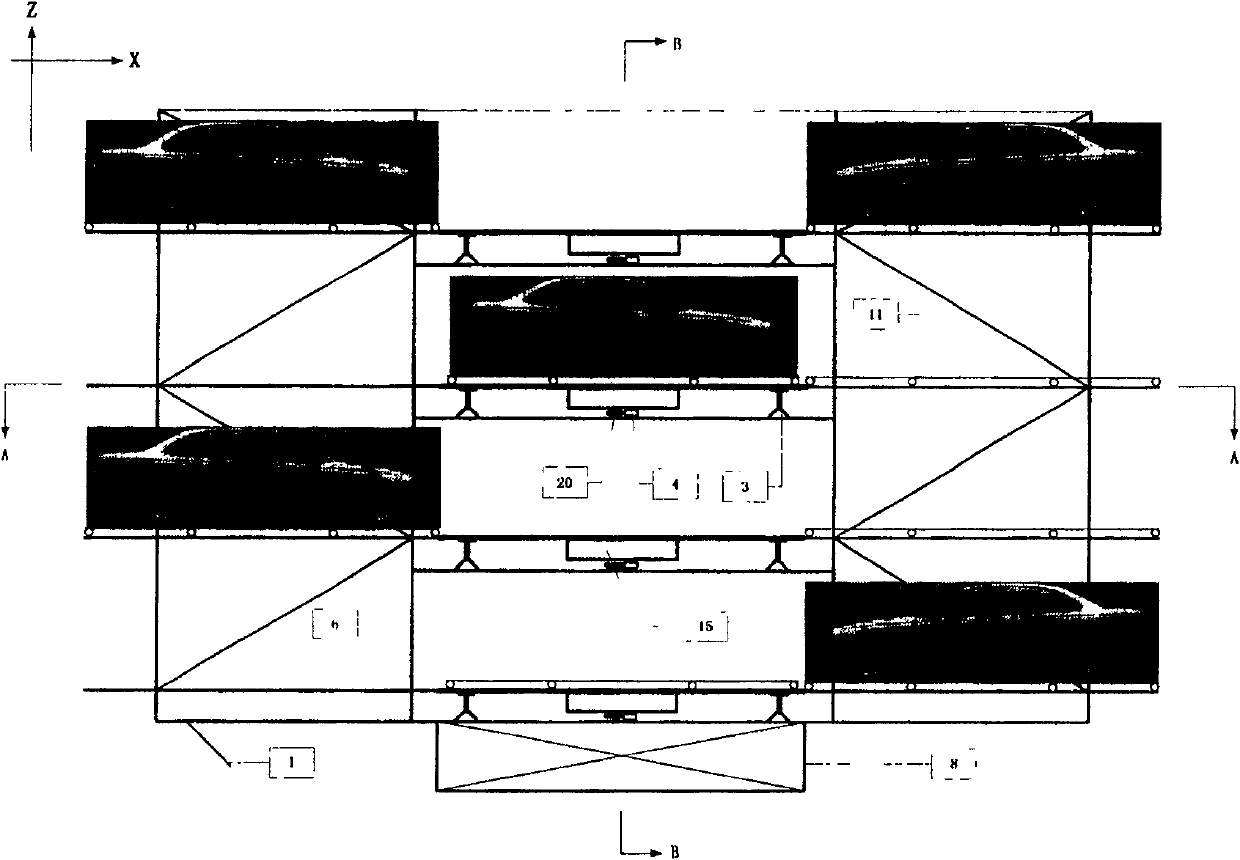

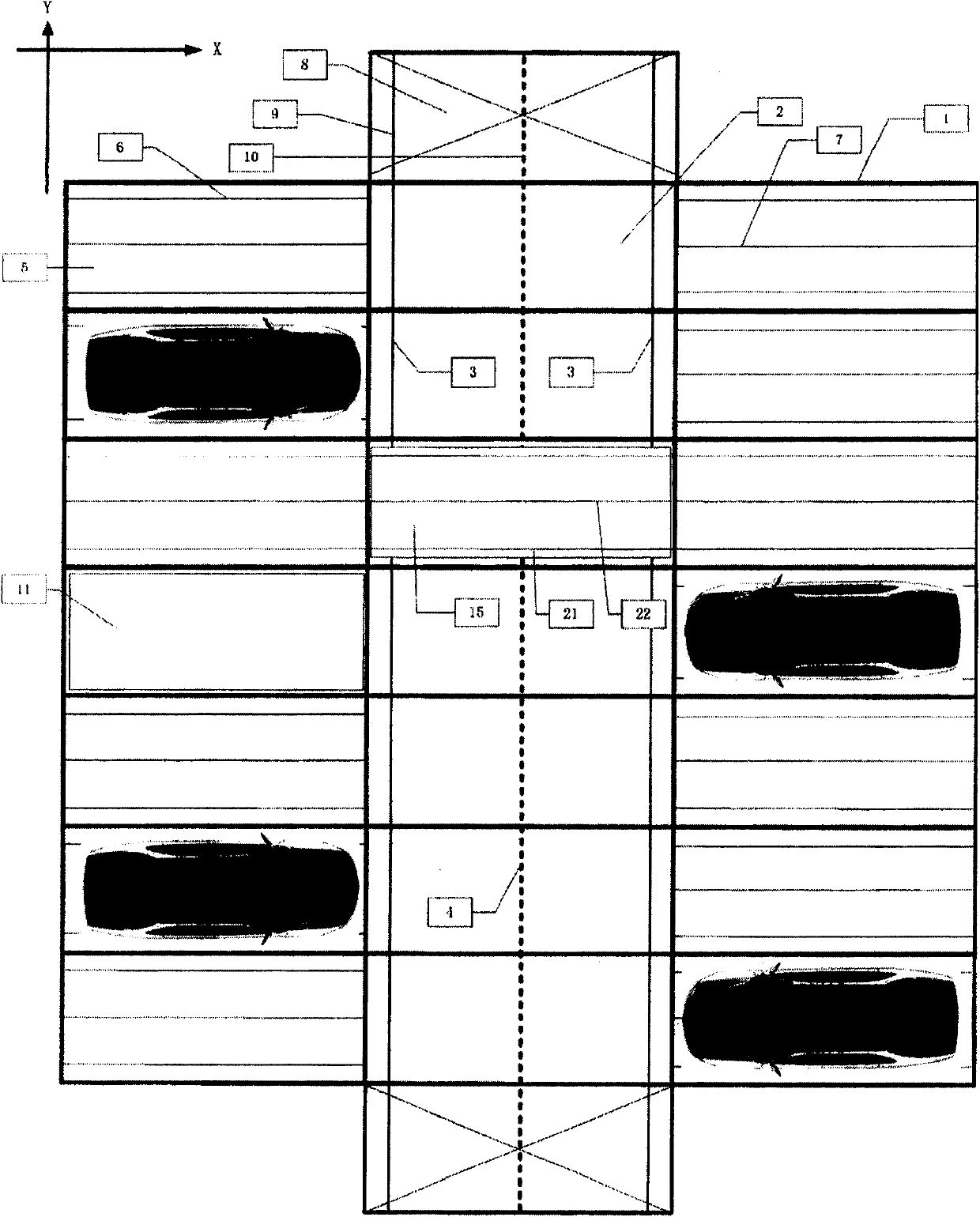

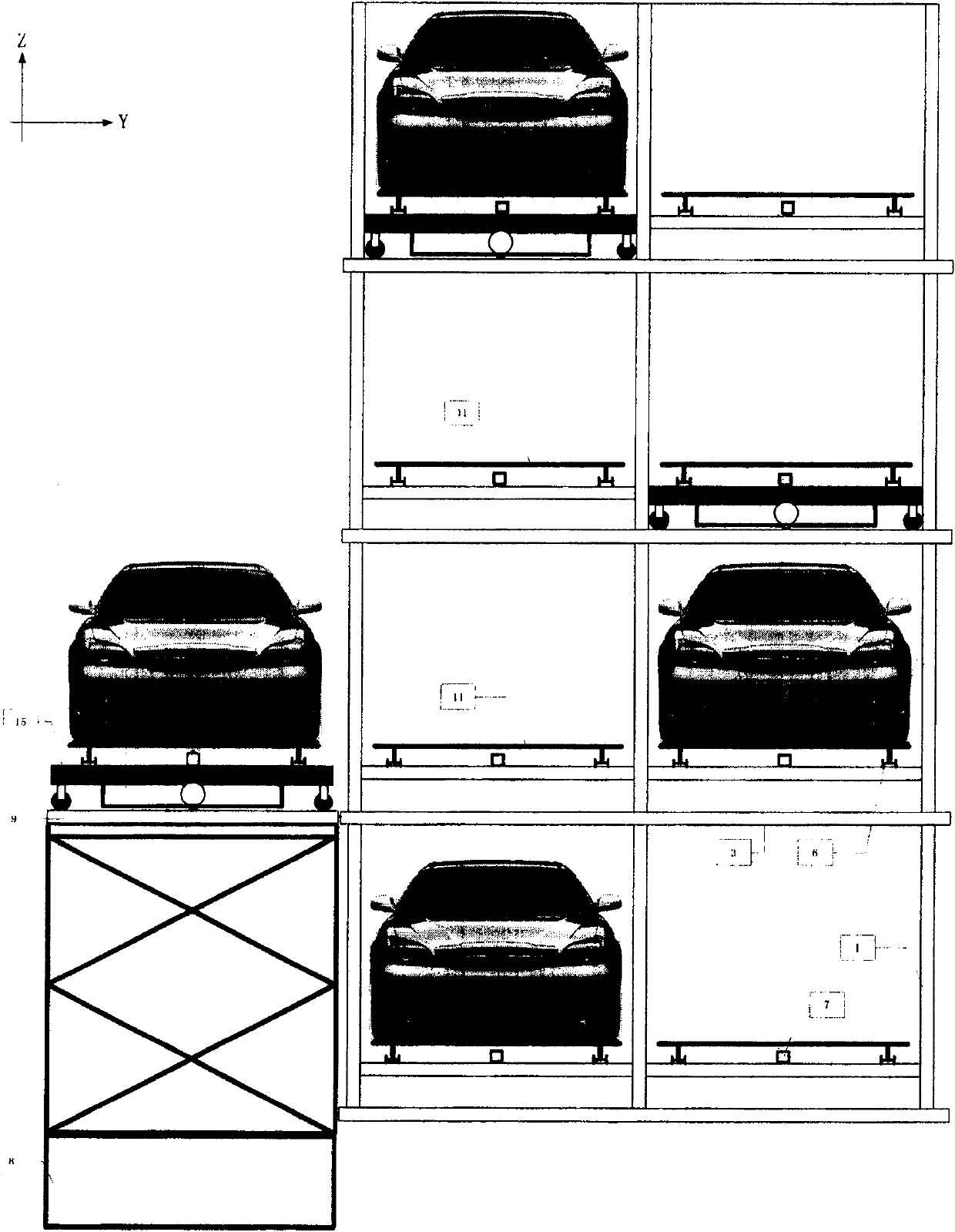

[0081] Such as figure 1 , 2 , shown in 3, a kind of three-dimensional garage comprises frame 1, vertical elevator 8, channel car 15, automatic control system, and its basic unit is provided with 2 entrances and exits, and storehouse height is no more than 8 floors.

[0082] Frame 1 plays the role of garage support and storage space 5 . Frame 1 is a multi-layer structure composed of steel, reinforced concrete or a mixture of the two, and each layer has the same structure.

[0083] The middle of each layer is a railed horizontal channel 2, and a pair of channel car tracks 3 are laid in parallel along the channel for the channel car 15 to drive. 4 and the lift channel car track 9 and the lift channel car rack 10 on the platform of the elevator 8 on the flat floor are extended and docked.

[0084] The storage positions 5 are arranged on both sides of the horizontal channel, and a pair of storage car tracks 6 are laid in parallel in each storage position 5. Push-pull rod guide g...

Embodiment 2

[0097] The basic setting is the same as the above example, the difference is that the entrance and exit assistance system is provided in this embodiment, see Figure 14 . The entrance and exit auxiliary system is made up of outbound track 33 and storage track 34, transition track 35, track lifter 36, track guide rail 37, storage car drive motor 38, chain 39, retractable push-pull trip hook 40.

[0098] A liftable outbound track 33 is established at the elevator outbound side, an upliftable storage track 34 is established at the elevator entry side, a transition track 35 is provided between the storage track 34 and the outbound track 33, and the transition track 35 The bottom of the warehouse is provided with a warehouse car transport device, and the storage and storage track lifting device 36 controls the lifting of the storage delivery track 33 and the storage track 34.

[0099] When the vehicle goes out and in storage, the track 33 and 34 for going out and in storage are fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com