Belt for continuously variable transmission (CVT) and CVT including the same

A technology of continuously variable transmission and pulleys, applied in V-shaped belts, transmission belts, belts/chains/gears, etc., can solve problems such as slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] An embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

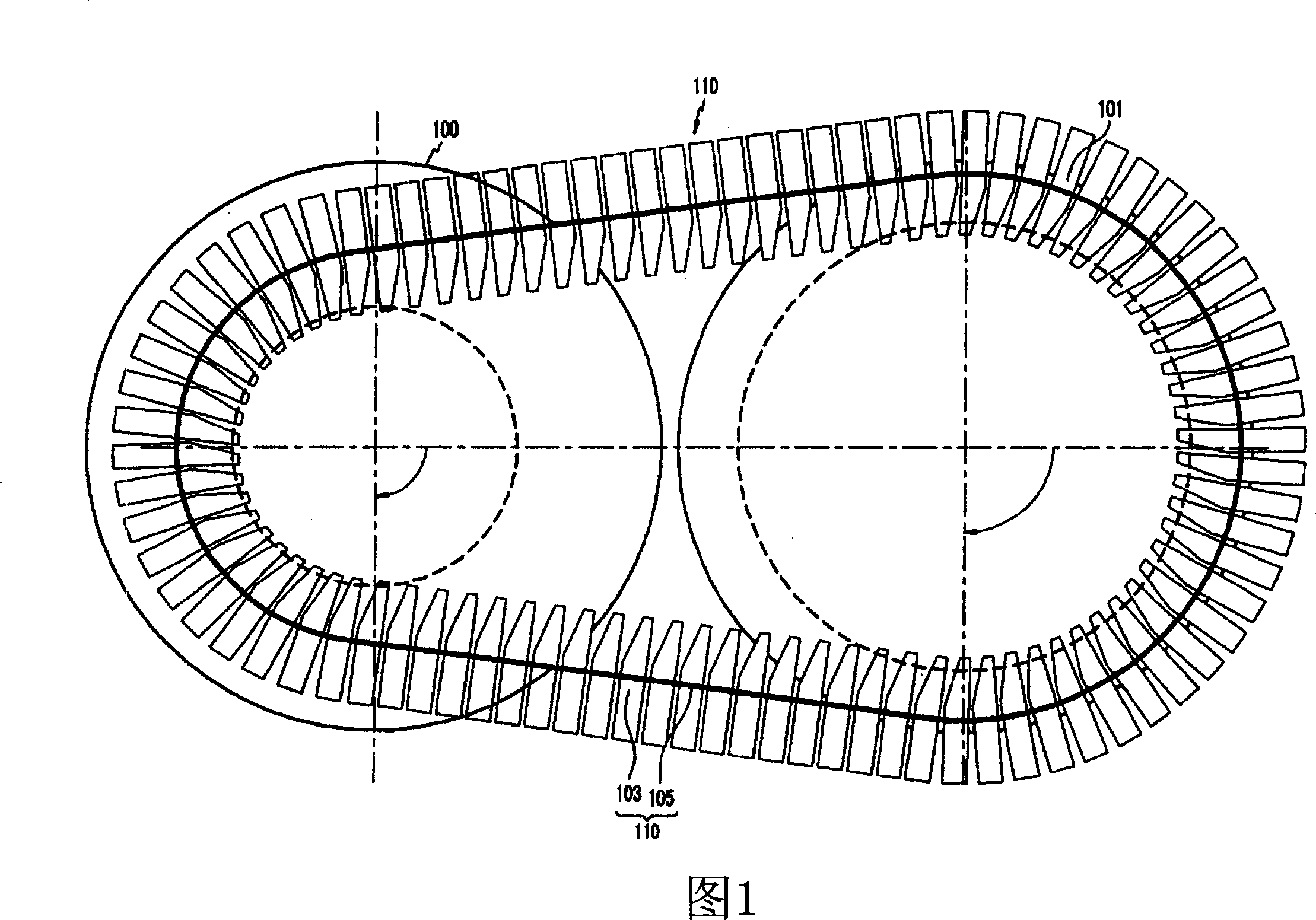

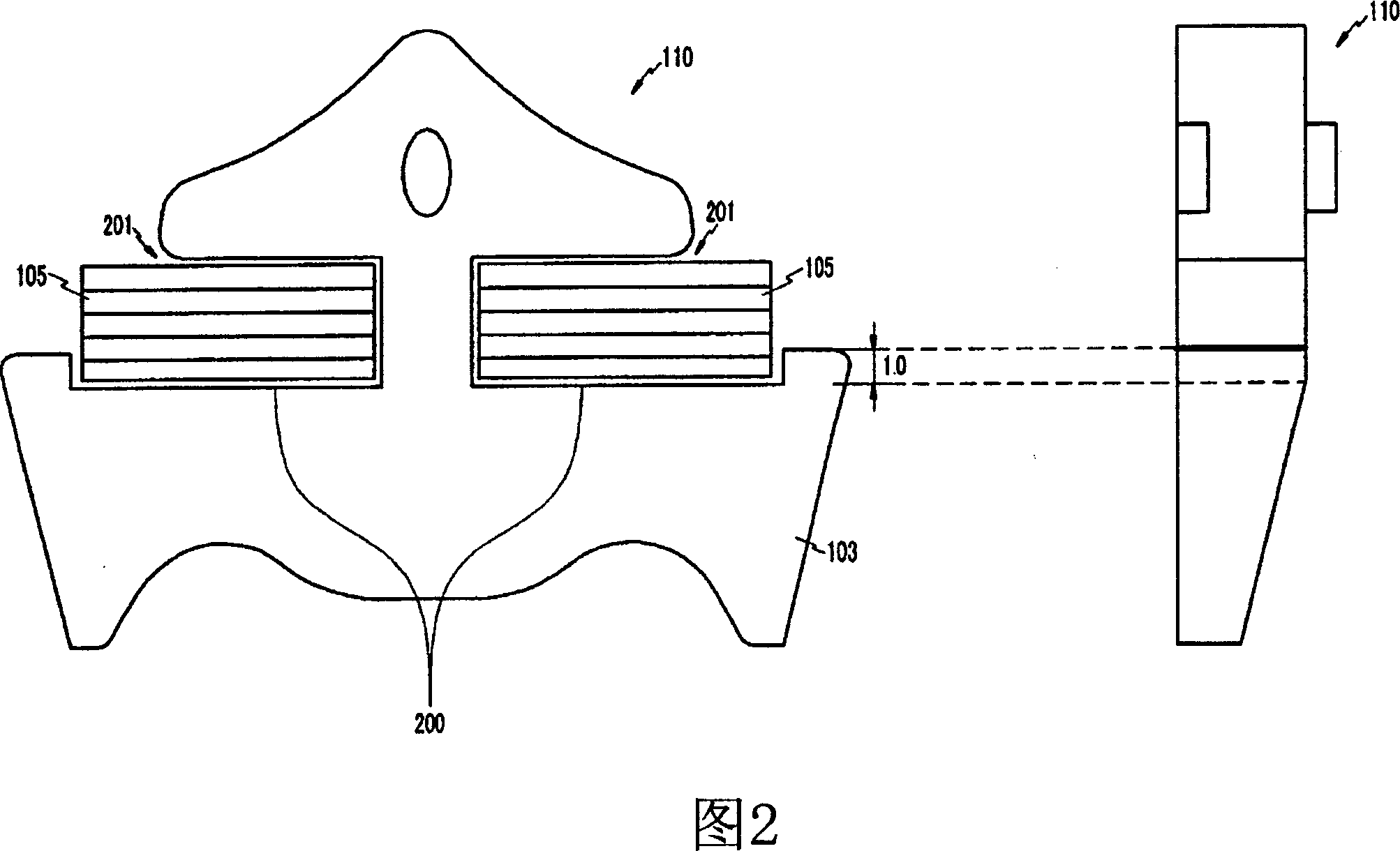

[0029] 1 shows a continuously variable transmission (CVT) according to an embodiment of the present invention, and FIG. 2 is a cross-sectional view showing a CVT belt according to an embodiment of the present invention.

[0030] As shown in FIG. 1 , according to an embodiment of the present invention, a continuously variable transmission CVT includes a primary pulley 100 , an auxiliary pulley 101 and a belt 110 .

[0031] Power is input to the primary pulley 100 and transmitted from the primary pulley 100 to the secondary pulley 101 .

[0032] The belt 110 transmits power from the primary pulley 100 to the secondary pulley 101 .

[0033] That is, if power is input to the primary pulley 100 , the power is transmitted to the secondary pulley 101 through the belt 110 .

[0034] The primary pulley 100 is connected with the driving shaft (not shown in the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap