Robot

A technology for a robot and an arm, applied in the field of robots, can solve problems such as the increase of the rotating joint part 110, the twisting of the wiring cable, and the easy occurrence of disconnection, and achieve the effects of being difficult to twist, preventing disconnection, and not easy to disconnect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

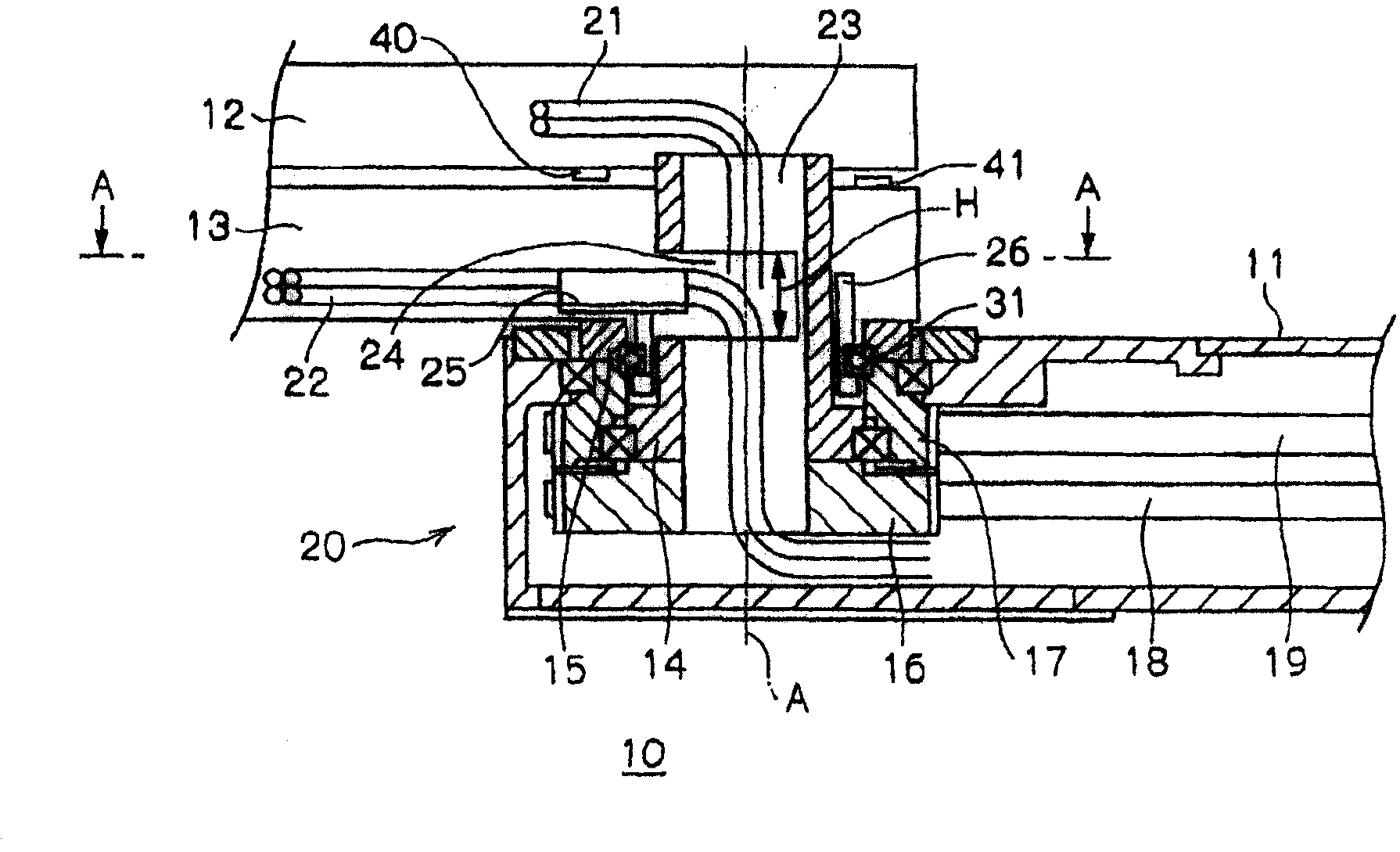

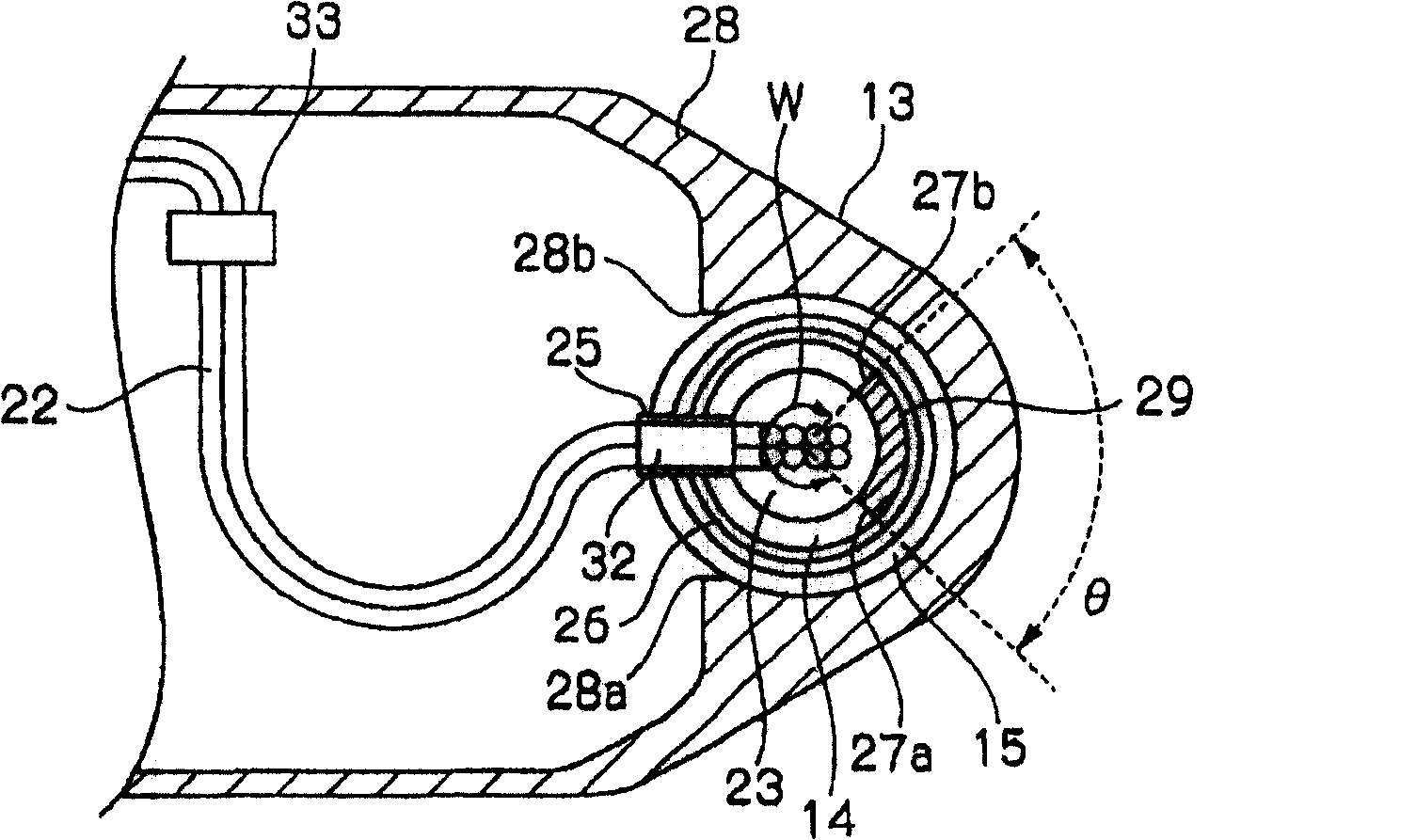

[0040] The best mode for carrying out the present invention will be described below with reference to the drawings. In addition, the robot of this invention is not limited to the following description and drawing in the range which has the technical characteristic. In addition, the "manipulator control system line" refers to the air pipe for the manipulator of the robot to suck in air to perform the workpiece gripping operation, the wiring cable for driving the chuck (Japanese: チヤツク) mechanism, and the signal for the sensor for confirming the suction operation. wires and other wiring cables. In addition, the manipulator control system wire is made of a flexible material (polyethylene, etc.) that has elasticity that does not interfere with joint motion.

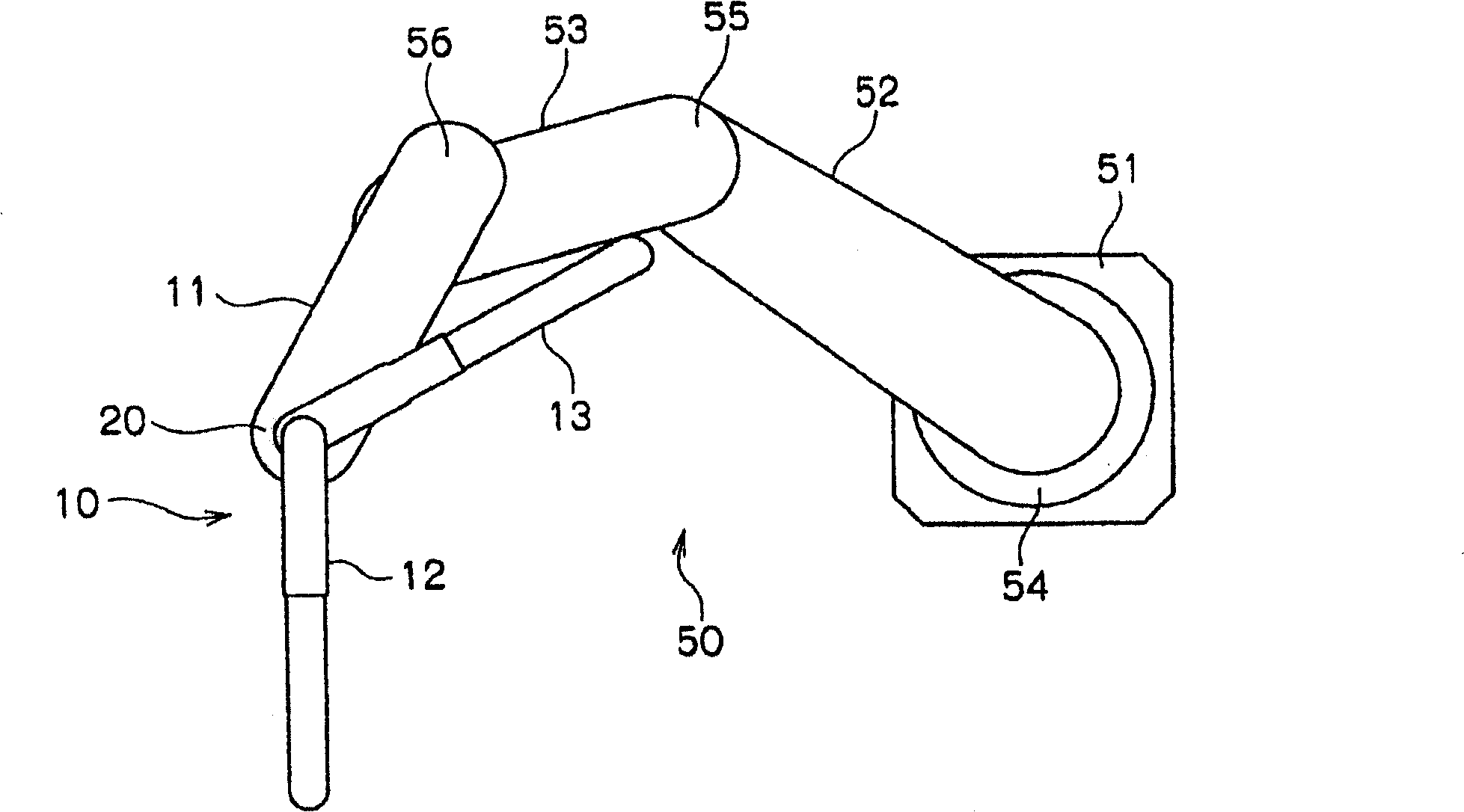

[0041] figure 1 It is a plan view showing an example of the robot of the present invention. figure 1 The shown robot 50 includes a revolving joint structure 10 with a windpipe and a cable handling structure as a manipulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com