Two stage belt drive mechanism for adjusting degree of tightness of strap

A technology of tightness adjustment and belt transmission, which is applied in transmission devices, belts/chains/gears, mechanical equipment, etc. It can solve the problems of loss of elasticity, unsuitability, short service life, etc., and achieve the effect of convenient replacement and adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

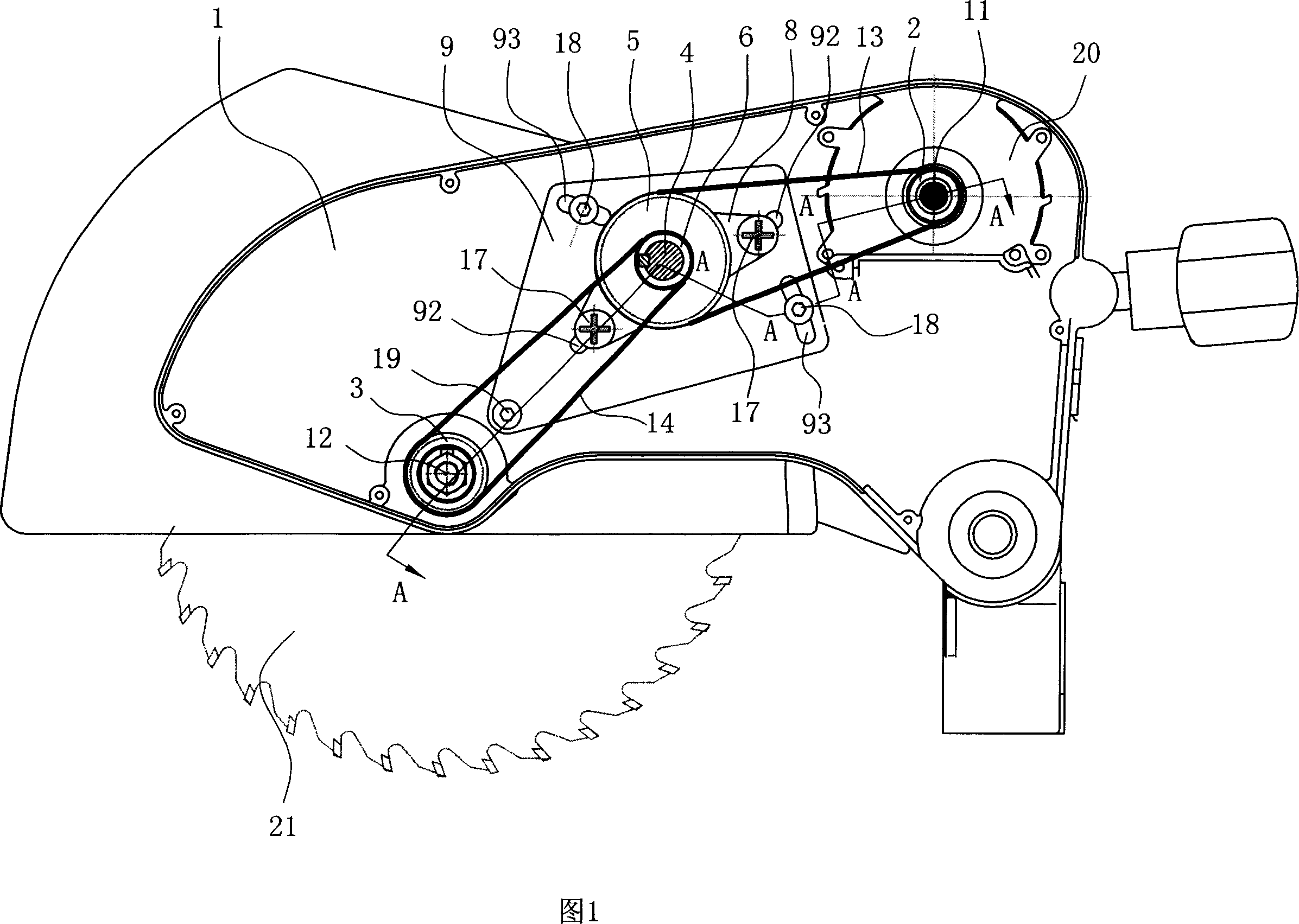

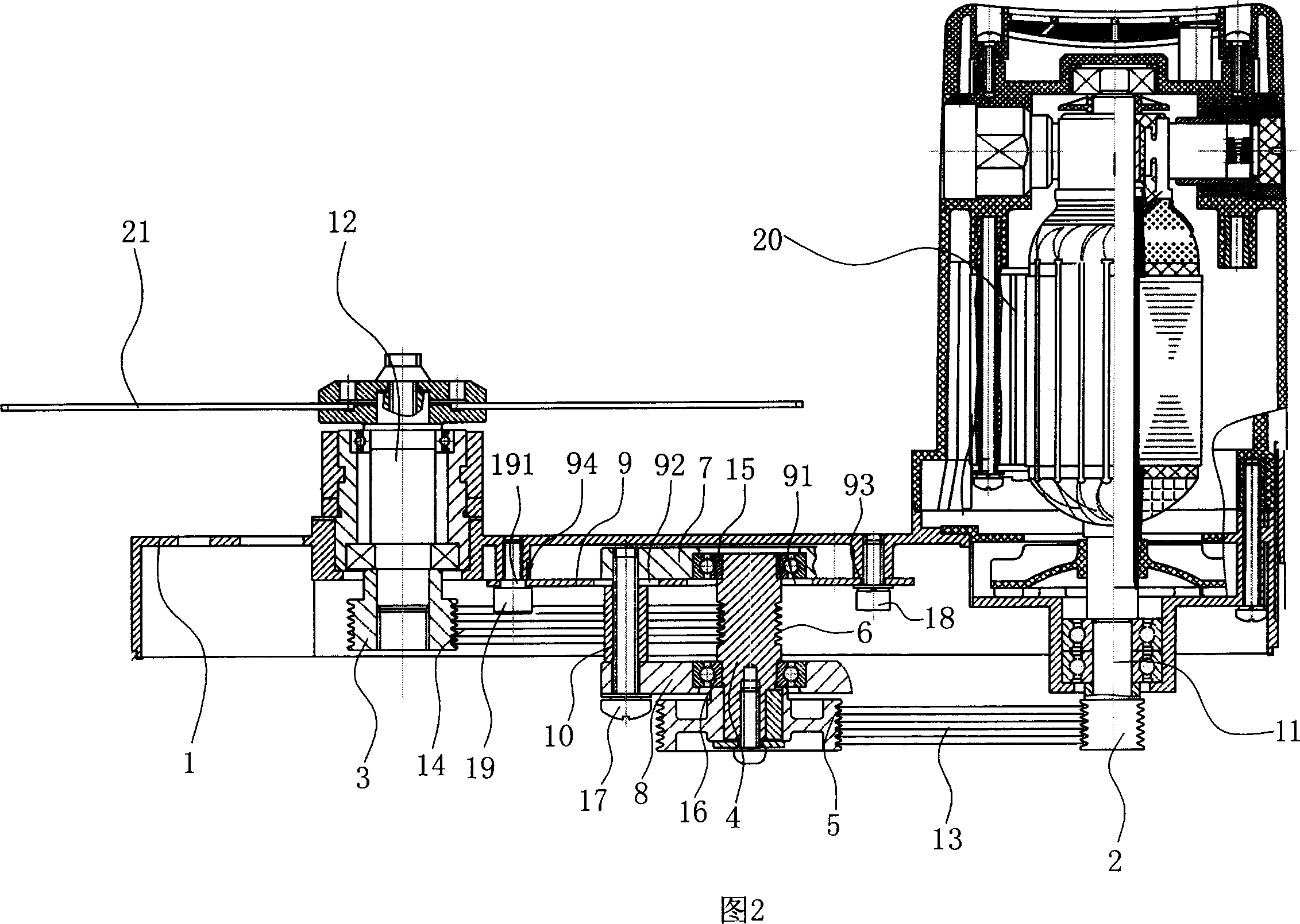

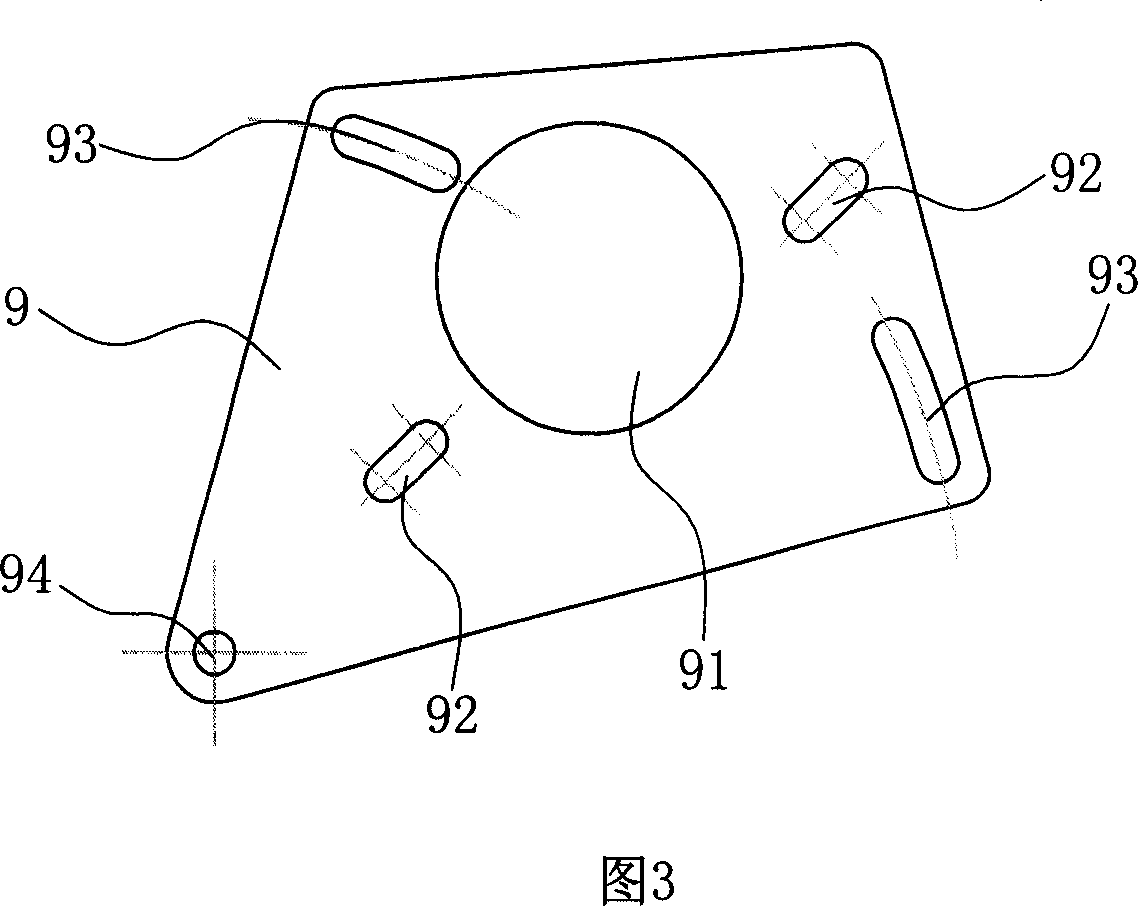

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0024] As shown in Figures 1 to 3, it is an embodiment of the present invention, which is a two-stage belt-driven belt tension adjustment mechanism applied to miter saws, table saws or reversing compound saws, including a frame 1, a first Transmission wheel 2, the second transmission wheel 3, the middle rotating shaft 4, the middle large wheel 5, the middle small wheel 6, the motor 20, the saw blade 21, the shape and size of the frame 1 can be designed according to the needs, and its main and the adjustment mechanism It is related to the mechanical structure of the application. The motor 20 is generally fixed on the casing 1 and the rotating shaft 11 of the power supply motor 20 passes through it. The output rotating shaft 12 is generally fixed on the casing 1;

[0025] The first transmission wheel 2 is connected to the rotating shaft 21 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com