Safety syringe

A technology of safety needles and pumps, applied in the direction of hypodermic injection equipment, etc., can solve problems such as infection, poor use effect, hazards, etc., and achieve the best safety and good injection efficacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

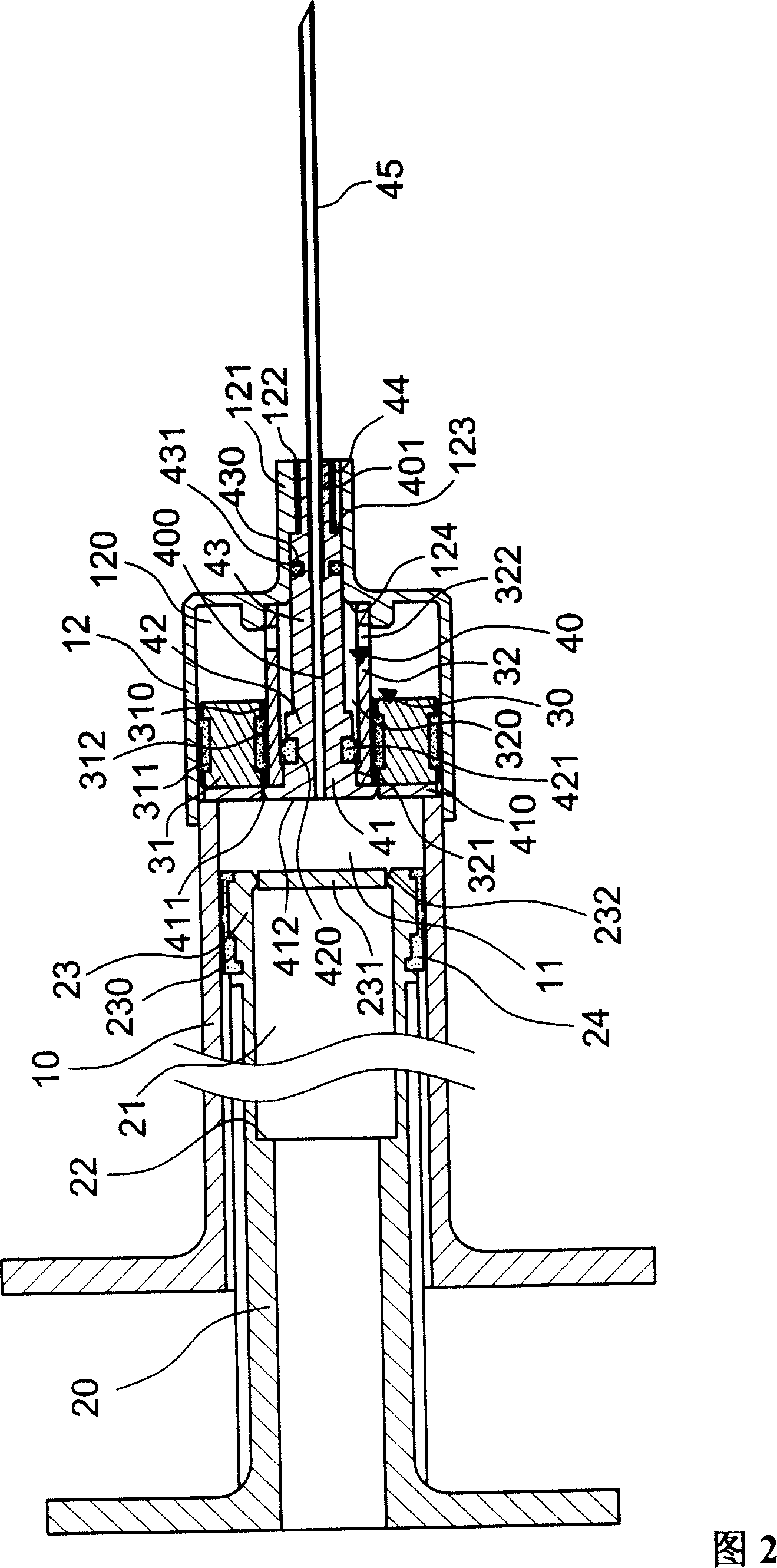

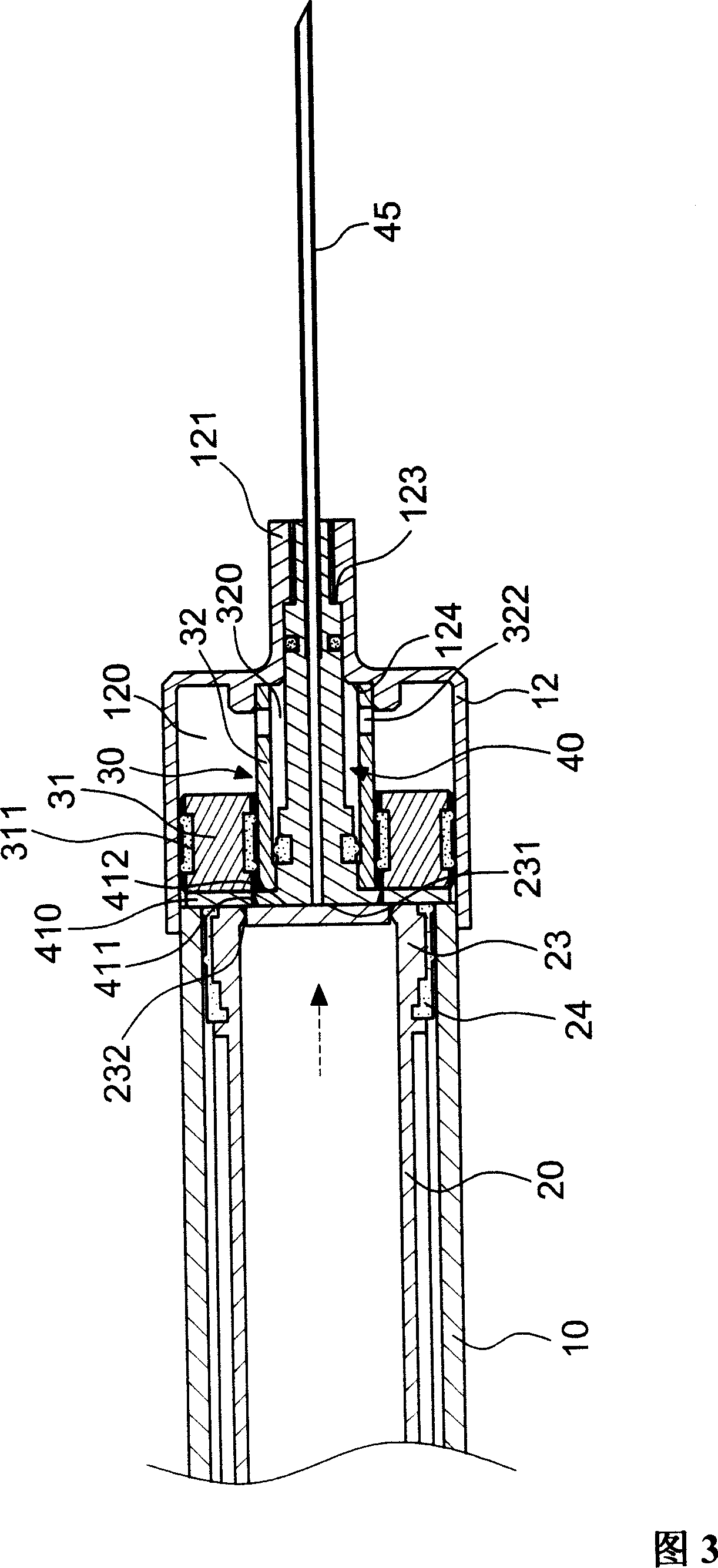

[0018] The present invention will be further described below in conjunction with the accompanying drawings

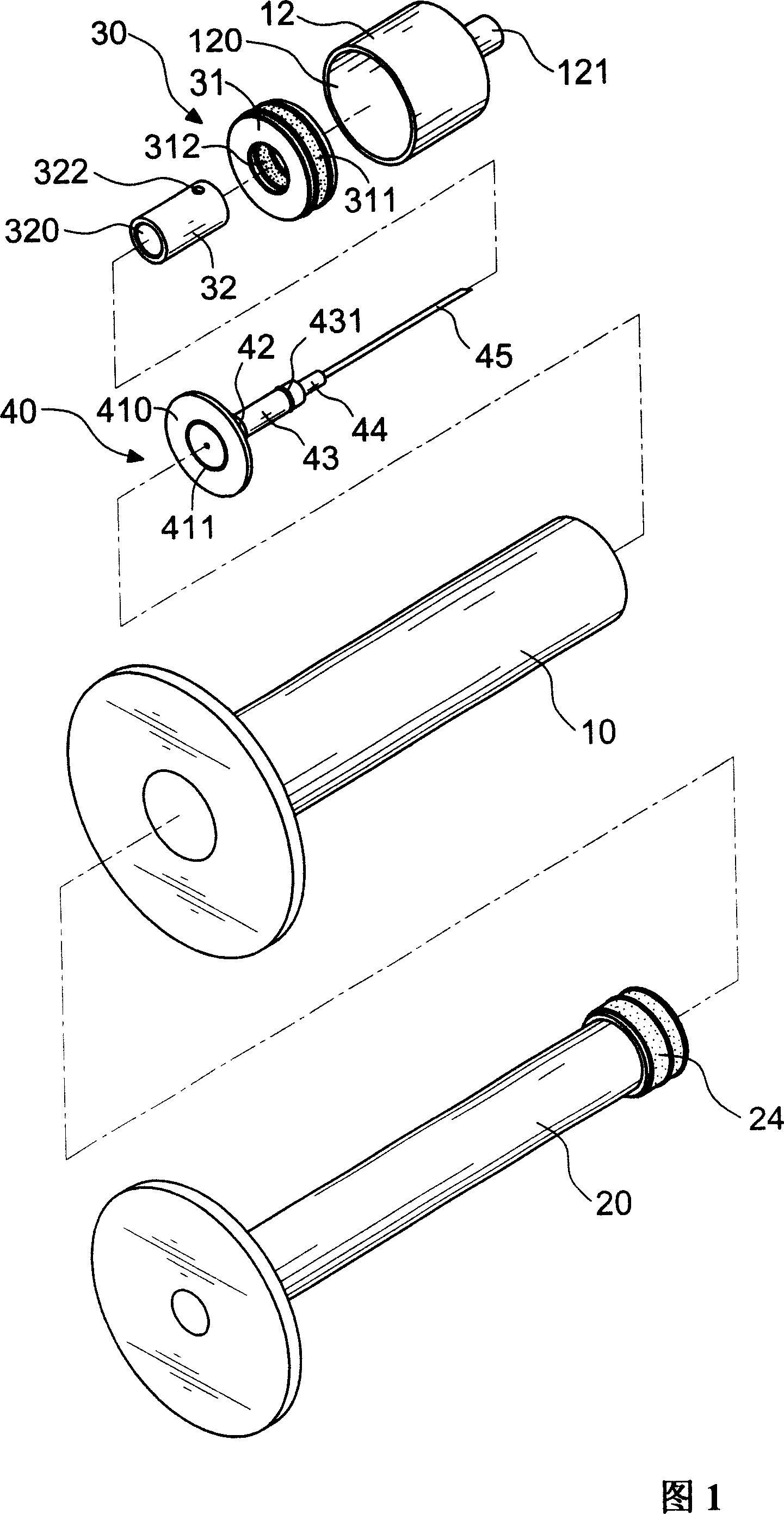

[0019] As shown in Figures 1 and 2, the safety syringe of the present invention mainly includes an outer tube 10, a push rod 20, a push assembly 30 and a needle seat 40, wherein:

[0020] The outer tube 10 is provided with a hollow channel 11 inside, and the outer tube sleeve 12 of the convex end 121 of the chamber 120 is provided at the end, and the convex end 121 is provided with a through hole 122 on the through hole 122. A first abutting surface 123 and A second abutting surface 124 having a diameter larger than that of the first abutting surface 123 is extended from one end.

[0021] The push rod 20 is disposed in the hollow channel 11 of the outer tube 10 and pushes in a tight fit. A accommodating cavity 21 is provided in the accommodating cavity 21 . The accommodating cavity 21 is provided with an abutting surface 22 , and an annular groove is provided on the per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com