Ship capable of side-wise propelling and reducing wave-making resistance

A wave-making resistance and lateral propulsion technology, which is applied to ship propulsion, propulsion components, and steering with propeller slip flow instead of rudder. Eliminate turbulence and vortex resistance, enhance heading stability, and reduce the effect of wave-making resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

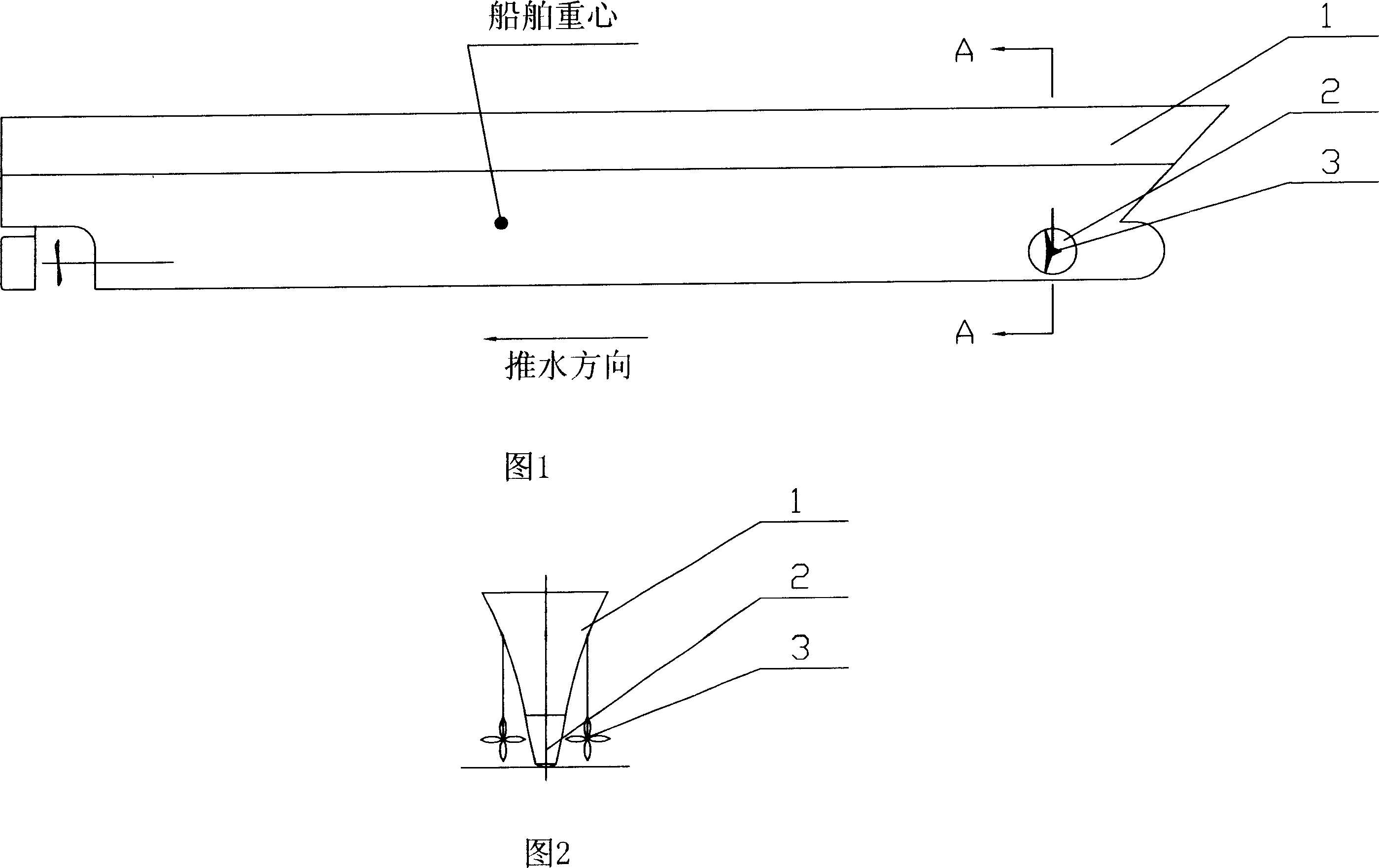

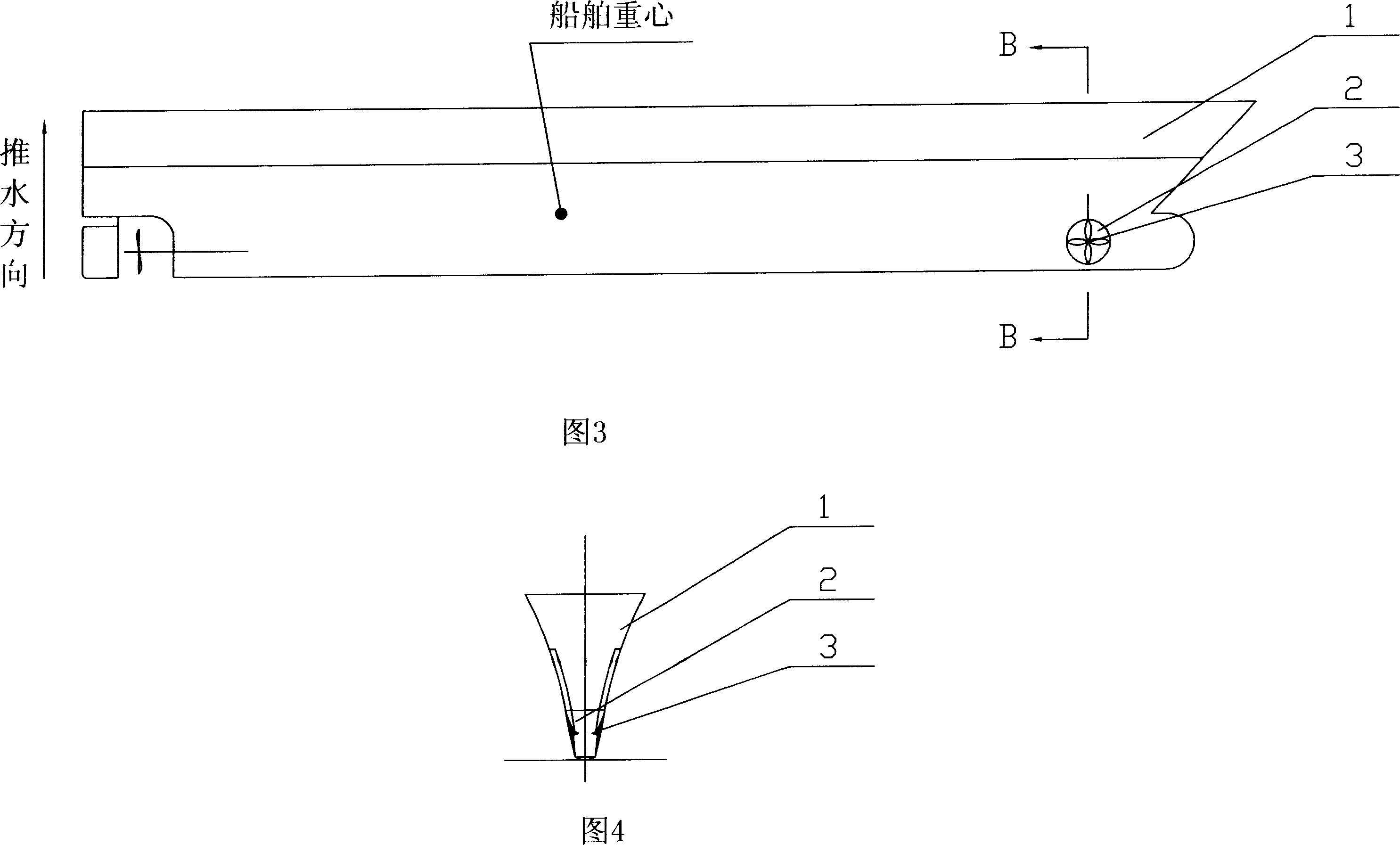

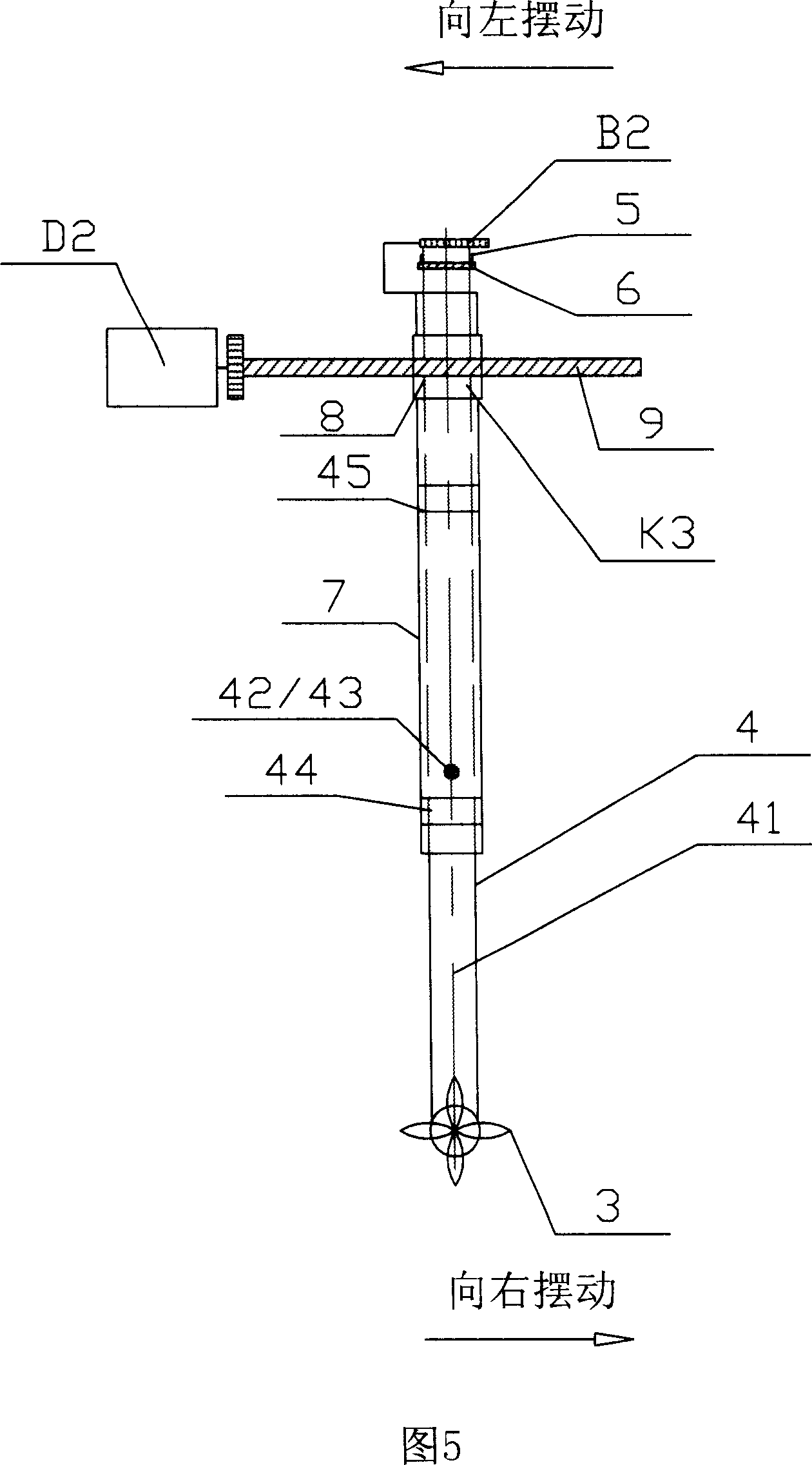

[0029] As shown in Figures 1 to 4, a ship that can be propelled laterally and can reduce wave-making resistance includes a hull 1, and several tunnels 2 that run through the hull 1 are set at the lateral position below the waterline of the hull 1, as shown in Figures 2 and 4. As shown in FIG. 4 , a propeller 3 is provided at both ends of each tunnel 2 , and a protective cover can be provided outside the propeller 3 , which can effectively prevent the propeller from being damaged by collisions with other objects. As shown in Fig. 5 and Fig. 6, the propeller 3 is connected with a driving device K1 for driving it to work and a full-turn device K2 for enabling the propeller 3 to generate thrust in any direction. The driving device K1 includes three pairs of gear transmission pairs A1, A2 / B1, B2 / C1, and C2, wherein the driving wheel A1 is coaxially installed with the power output shaft 10, the driven wheel A2 is coaxially installed with the driven shaft 11, and the driving wheel A1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com