Variable exhaust pipe volume module type pulse converter boost device of turbocharging diesel engine

A technology of turbocharger and pulse converter, which is applied in the direction of exhaust device, muffler device, engine components, etc., can solve the problem that the volume of the exhaust pipe cannot be adjusted, and achieve the effect of simple structure, reasonable design and excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

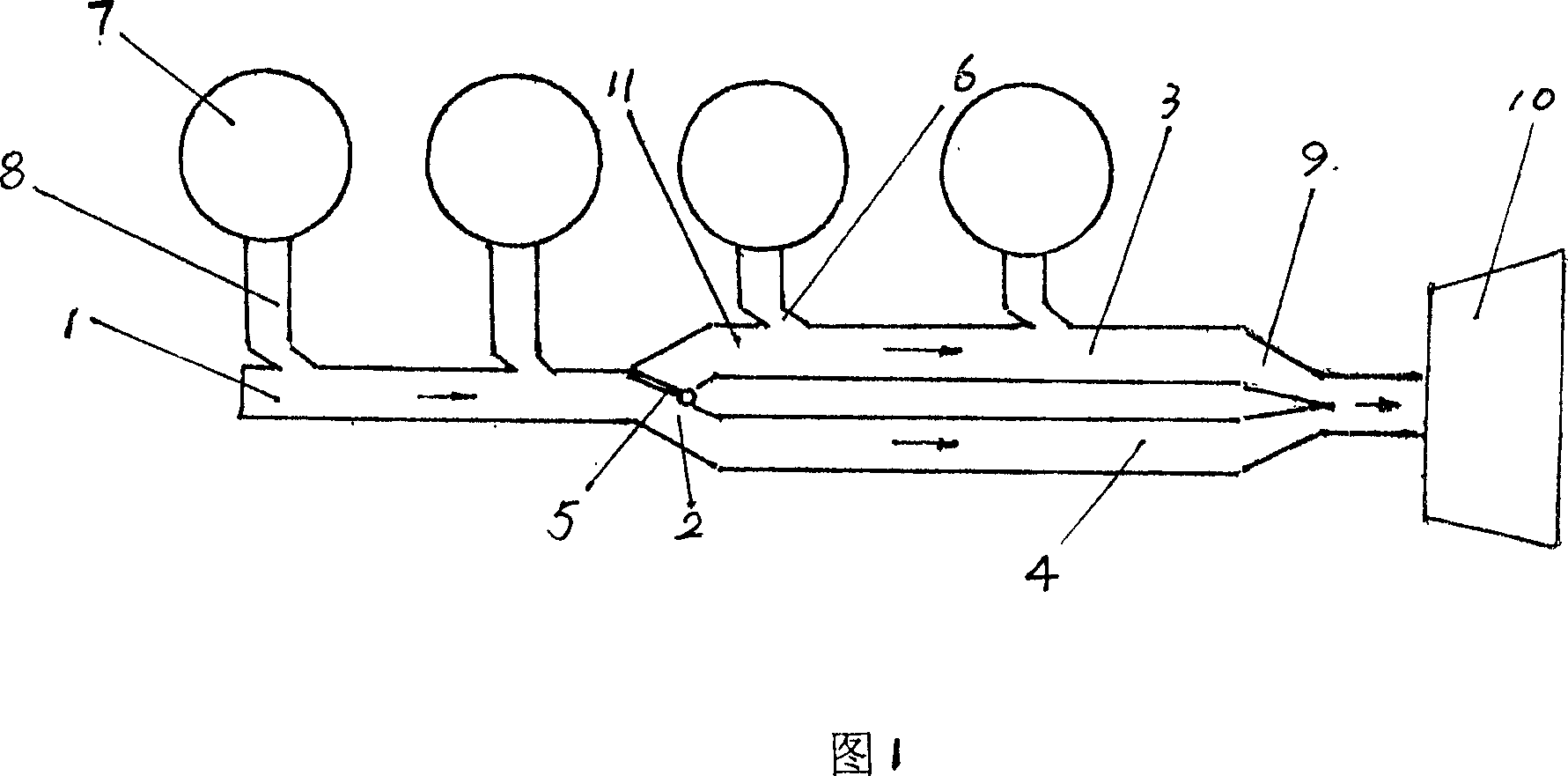

[0008] As shown in Figure 1, the present invention is made up of modular pulse converter module, auxiliary exhaust pipe 4, three-way pipe 2 and two-position control valve 5, and modular pulse converter module is composed of ejector 6 and Cylinder exhaust pipe 11 constitutes, ejector 6 is installed on the side of exhaust passage 8 of cylinder 7, cylinder exhaust pipe 11 of upstream cylinder constitutes upstream exhaust pipe 1, cylinder exhaust pipe 11 of downstream cylinder constitutes main exhaust Pipe 3, the downstream end of the upstream exhaust pipe 1 is connected to the upstream end of the three-way pipe 2, and the two downstream ends of the three-way pipe 2 are respectively connected to the upstream ends of the main exhaust pipe 3 and the auxiliary exhaust pipe 4 A two-position control valve 5 is installed at the intersection of the three-way pipe 2, and the downstream ends of the main exhaust pipe 3 and the auxiliary exhaust pipe 4 are respectively connected with the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com