Equipment and method for manufacturing capillary reactors

A technology of capillary tube and reactor, which is applied in the production equipment and field of capillary reactor, can solve the problems of invisible reaction process, limited application field, large consumption of raw materials, etc., and achieve the effect of simple structure, convenient processing and continuous synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

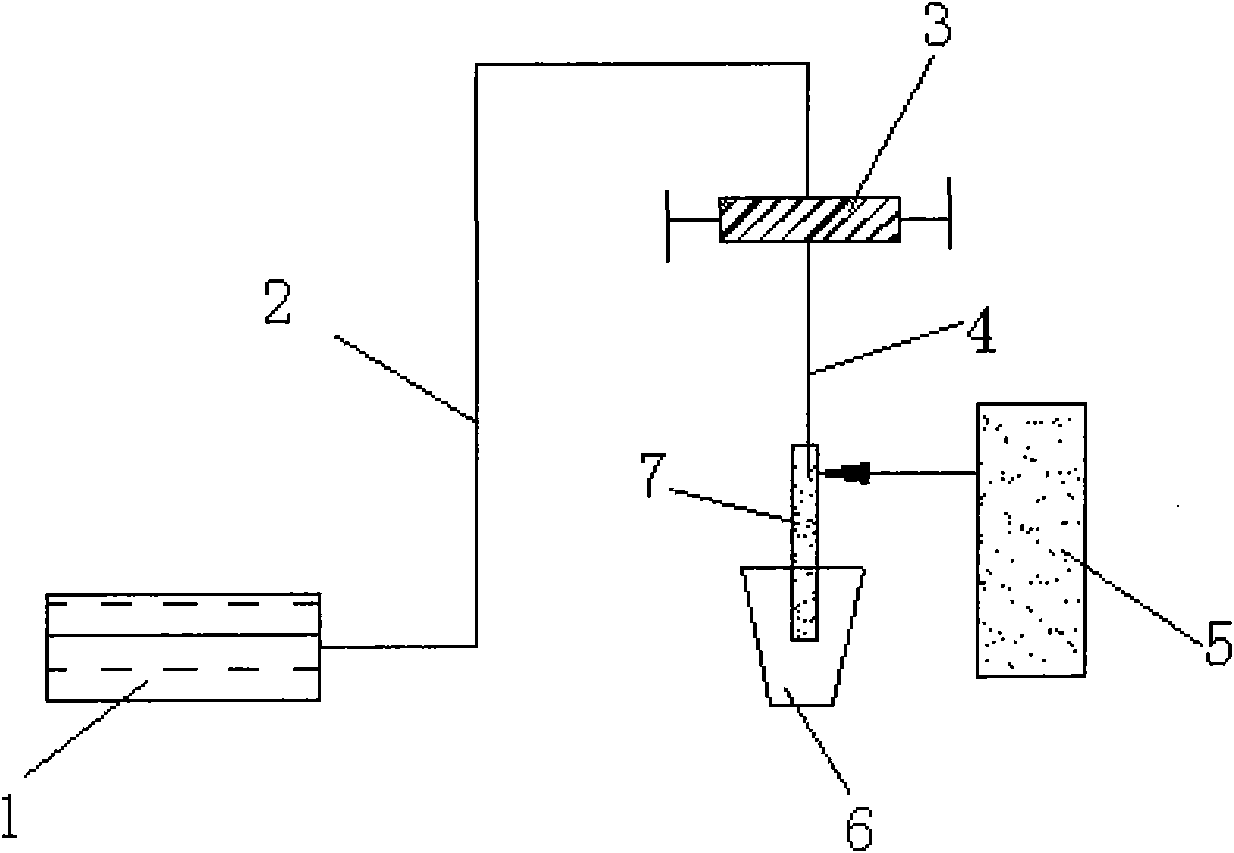

[0024] refer to figure 1 : A kind of manufacturing equipment of capillary reactor, is made up of capillary reactor main body and welding sealing synthesis device, described welding sealing synthesis device comprises vacuum pump 1, liquid nitrogen tank 6, fixing device and is used for capillary reactor end welding Sealed oxyhydrogen flame device 5, the vacuum pump 1 is connected to the capillary reactor main body 7, and the capillary reactor main body 7 is fixed in the liquid nitrogen tank 6 by the fixing device.

[0025] The main body 7 of the capillary reactor is connected to the vacuum pump 1 through a pipeline 4 with plastic tubes connected at both ends. The vacuum pump is provided with a seamless steel pipe 2 and a valve 3, one end of the valve 3 is connected to the seamless steel pipe 2, and the other end is connected to the pipe 4 with plastic pipes at both ends.

[0026] Utilize the fabrication equipment of above-mentioned capillary reactor to degrade polycarbonate (PC...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com