Terminal fixing structure

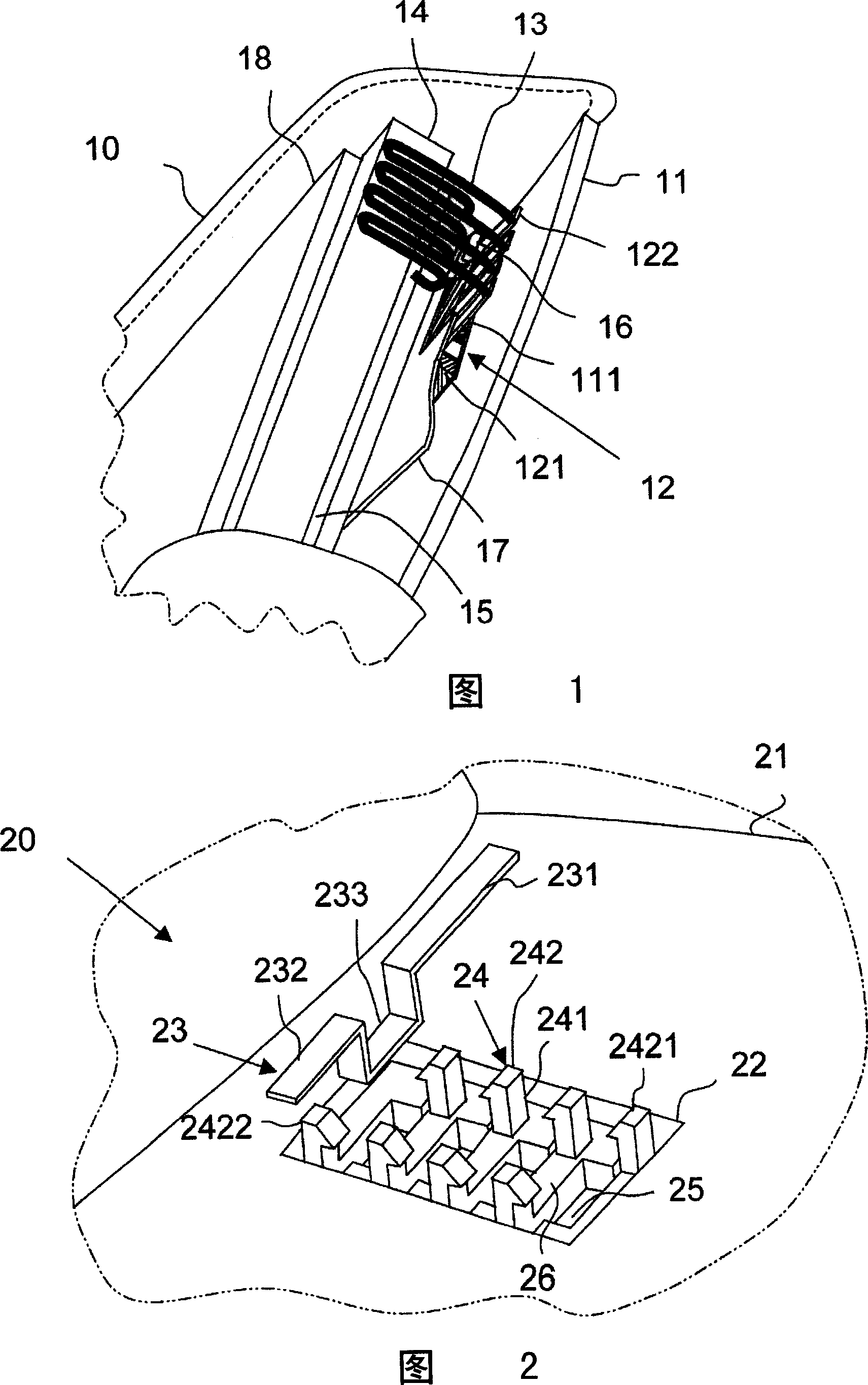

A terminal fixing and fixing column technology, which is applied in the direction of fixing/insulating contact components, electrical components, coupling devices, etc., can solve the problems of the contact end of the terminal 12 sinking, the bonding force of the fixing patch 17 being weakened by heat, and affecting the fixing of the terminal 12, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

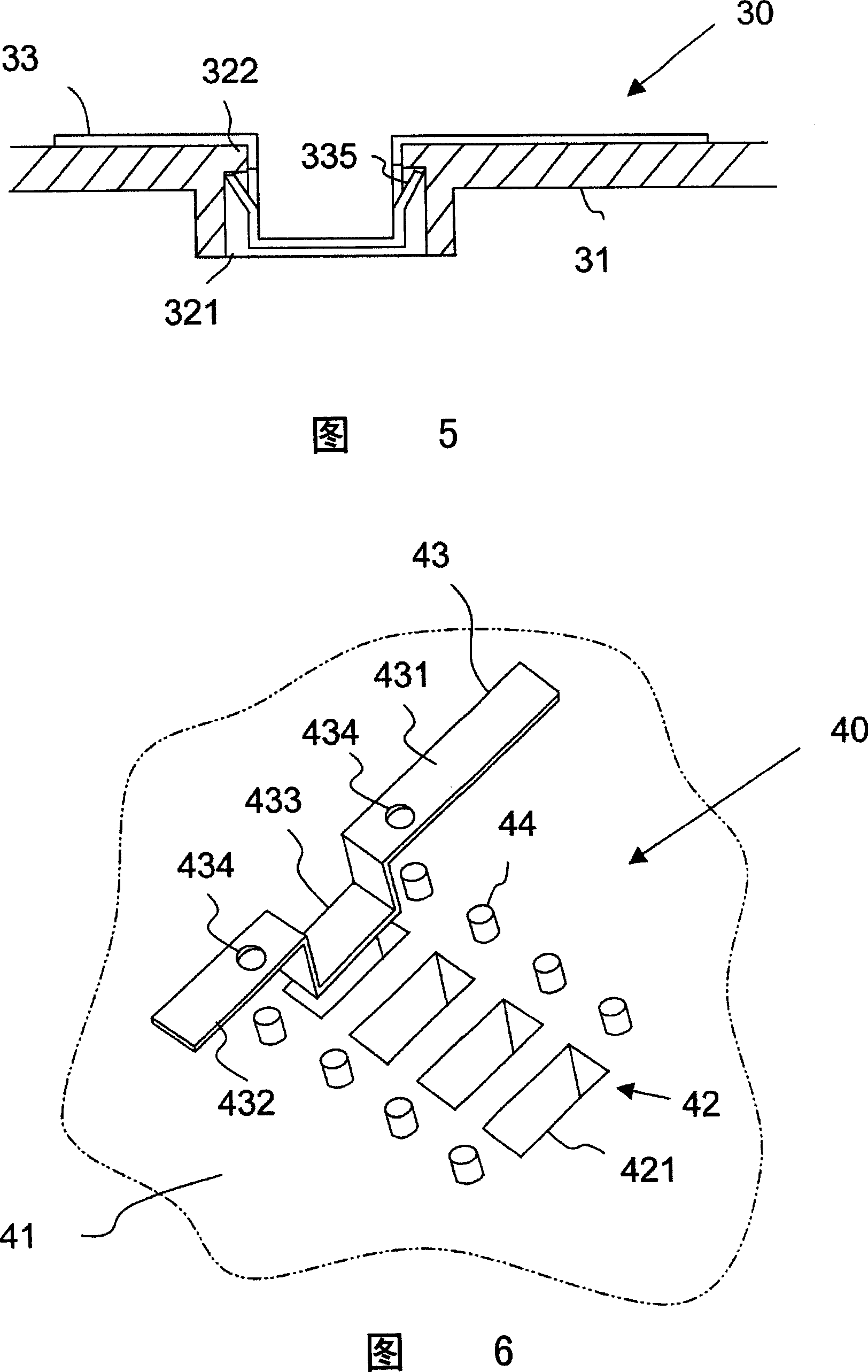

[0016] In order to achieve the above object, the present invention adopts the technical means and its effects, and gives preferred embodiments, which are described as follows in conjunction with the drawings.

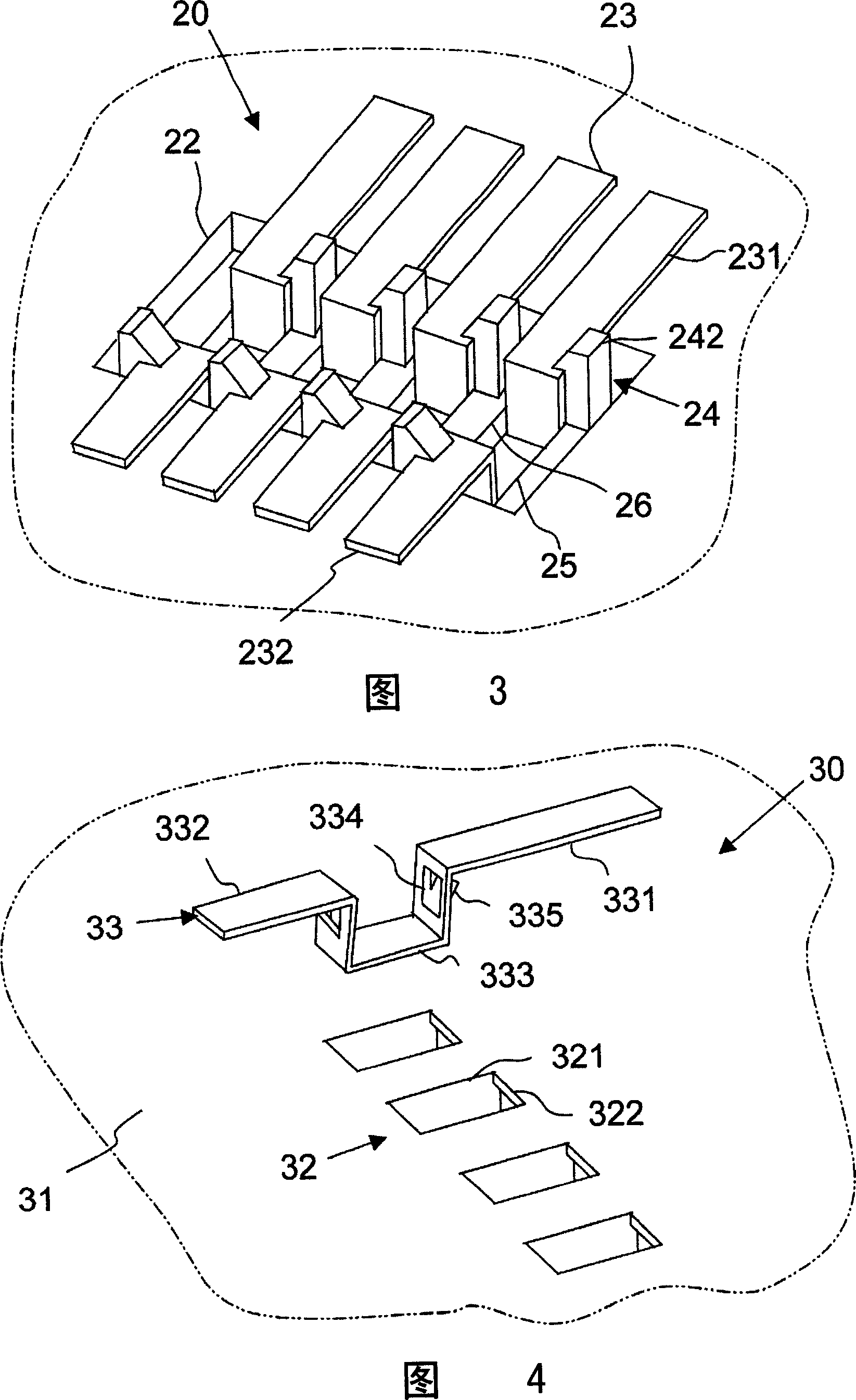

[0017] Please refer to FIG. 2 , which shows a terminal fixing structure 20 according to the first embodiment of the present invention, including a housing 21 , a positioning groove 22 , and a conductive sheet 23 . Mainly on the casing 21 of the electronic product, such as the bottom case of the battery, the positioning groove 22 is directly dug, and a plurality of conductive sheets 23 are directly embedded and fixed in the positioning groove 22 to form the terminal fixing structure 20 .

[0018] Wherein, the positioning groove 22 has a plurality of groups of conductive pieces 23 positioning units, the positioning unit is composed of snap buttons 24, through holes 25 and supporting ribs 26, etc., and the slightly N-shaped supporting ribs 26 are arranged in the positioning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com