Detection equipment of performance of automobile one-way valve

A technology for testing equipment and one-way valves, which is applied in the direction of measuring devices, testing of mechanical components, and testing of machine/structural components, etc. It can solve the problems of unsuitable vehicle check valves, prone to bursting, and poor detection results. Achieve the effect of convenient and reliable fixing, stable and firm fixing, and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

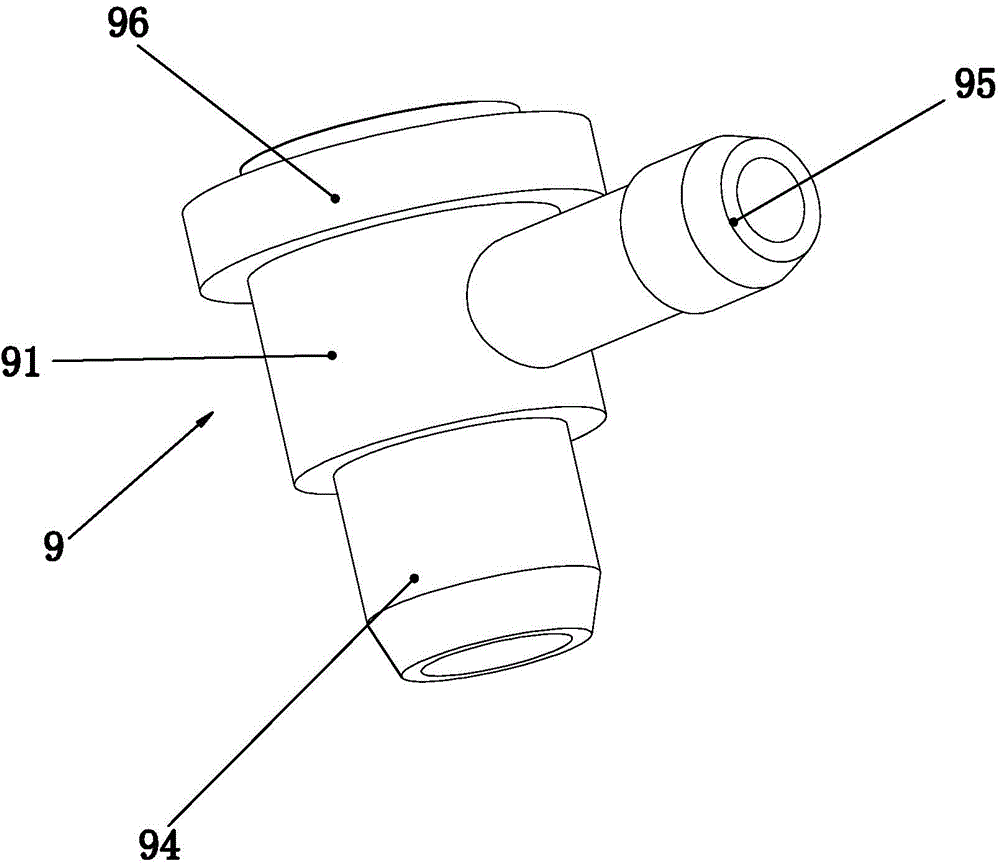

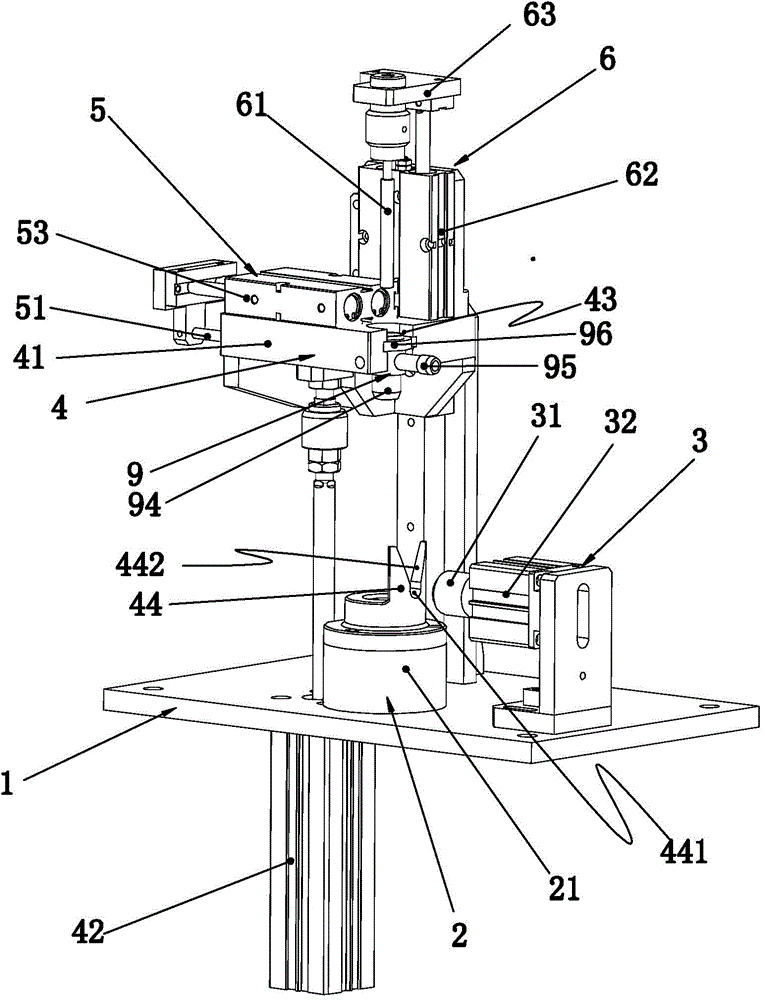

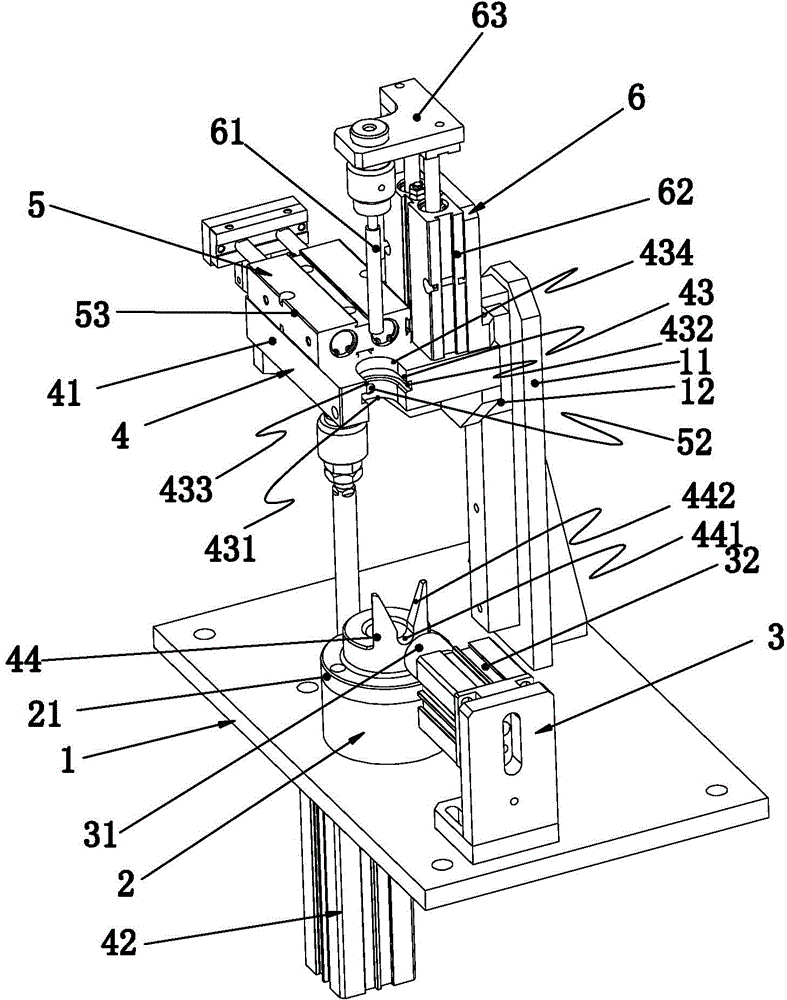

[0028] See attached Figure 1-5 , a performance testing device for an automobile check valve disclosed by the present invention, comprising an organic base 1, a detection station is provided on the base 1, and a detection device is provided on the detection station, wherein the detection station can be set as required Its quantity, thus realizes multi-station operation; Described detection device comprises the air intake pipe blocking mechanism 2 of one-way valve air intake pipe positioning blockage, the suction pipe blocking mechanism 3 of one-way valve suction pipe positioning blockage, And the valve fixing mechanism 4 of fixing check valve; Described intake pipe blocking mechanism 2 includes intake pipe blocking seat 21, and intake pipe blocking seat 21 is provided with realizing ventilating or extracting air in the check valve intake pipe The air intake pipe controls the airway 22, and the air extraction pipe blocking mechanism 3 includes an air extraction pipe blocking s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com