Method and motor controll unit

A motor control and pre-control technology, which is applied in electrical control, engine control, fuel injection control, etc., can solve the problems of inaccuracy and slow matching, and achieve the effect of precise triggering and precise pre-control combination characteristic curve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

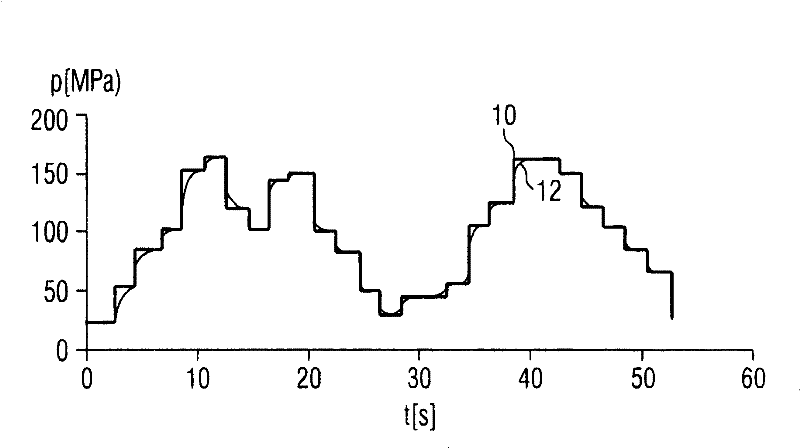

[0025] Figure 1A Shows a rated pressure change curve 10 in a rail of a common rail system with a pressure regulating valve and a pressure change curve 12 measured in a test bench. The pre-control combination characteristics of the pressure regulating valve are controlled according to the prior art curve. On the abscissa, the time t in seconds s is plotted, and on the ordinate, the pressure p in MPa is plotted. In the common rail system, a stable regulator is provided, which ensures that the system approaches the operating point accordingly. In the steady state, in this resolution, there is almost no difference between the rated pressure and the measured pressure in the rail. Under transient conditions, the deviation between the rated pressure 10 and the measured pressure 12 can be seen.

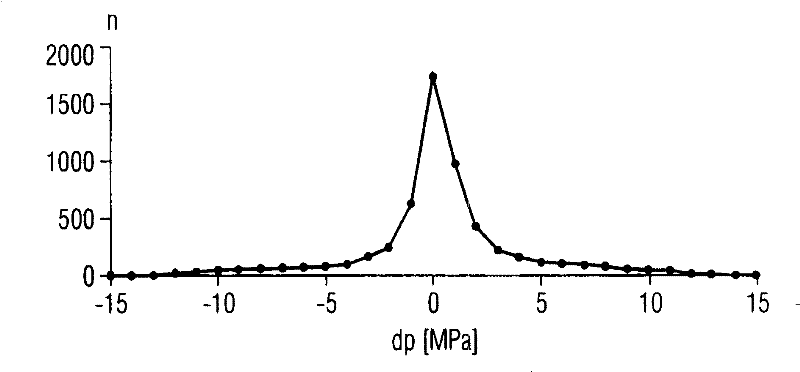

[0026] Figure 1B Right Figure 1A The measured pressure profile shown in shows the distribution of the control deviation dp between the measured pressure 12 and the setpoint pressure 10. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com