Cyclone type secondary separation dust cup of vacuum cleaner

A secondary separation and cyclone-type technology, applied in the field of vacuum cleaner accessories, can solve the problems of reduced dust collection efficiency and unsatisfactory separation of air and dust, and achieve the effect of increased dust collection capacity, simple structure, and convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

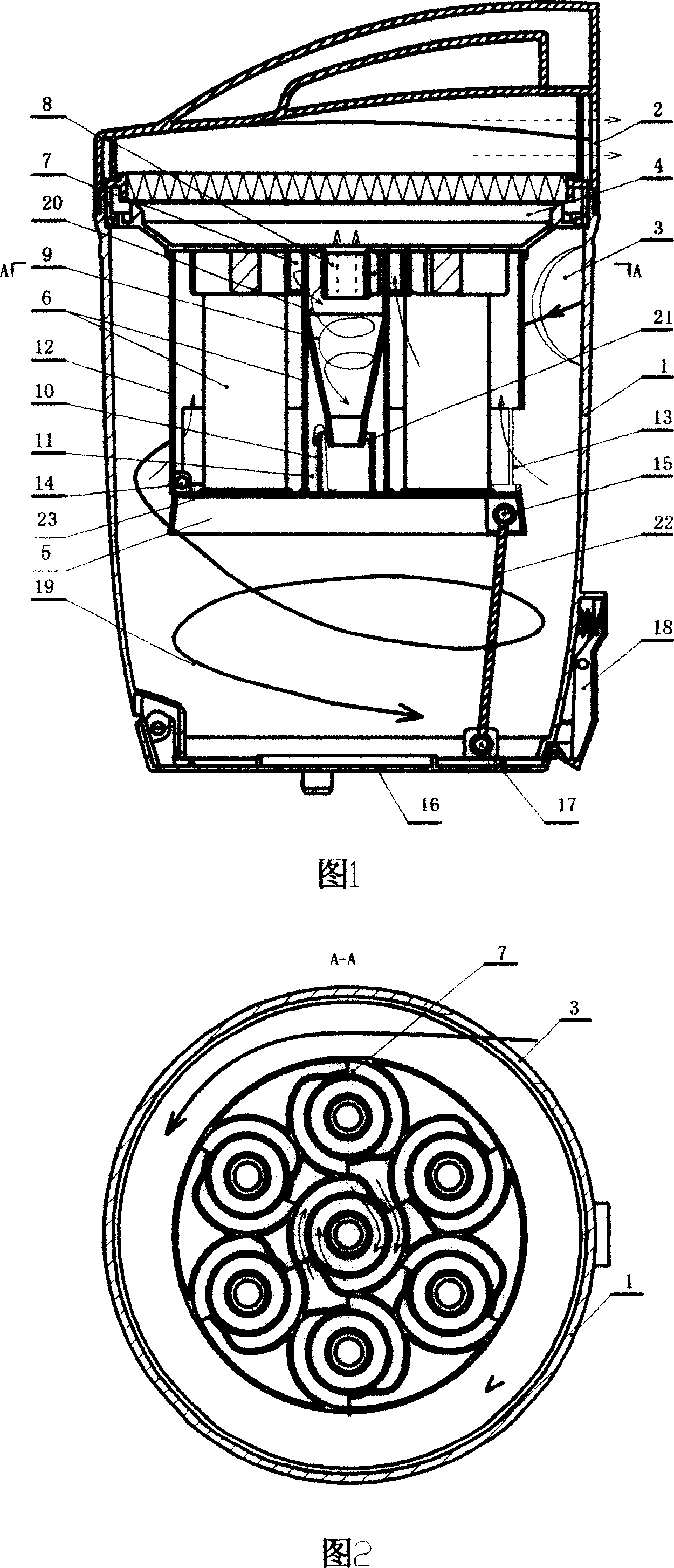

[0011] As shown in Figure 1 and Figure 2, the cyclone-type secondary separation dust cup of the vacuum cleaner includes a housing 1 of the dust cup, an air outlet 2 opened on the housing and an air inlet 3 tangential to the surrounding wall of the housing, placed in the housing Separators and scaffolds in vivo4. The air inlet 13 of the separator is arranged at the lower half of the annular cover 12 . Its position is lower than the air inlet 3 of the casing. There are more than two cylinders 6 arranged side by side with tangential air inlets 7 on the upper ends arranged in the annular cover, and seven cylinders are arranged side by side in the figure. The top of the annular cover and cylinder body are connected with the support. There can be more than two tangential air inlets 7 on the upper end of the cylindrical body 6, and there are two air inlets 7 in the figure. There is a short air outlet pipe 8 coaxially arranged in each cylinder and communicated with the bottom hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com