Efficient degassing structure for glass fiber reinforced plastics production workshop

A production workshop and glass fiber reinforced plastic technology, which is applied in gas treatment, dispersed particle filtration, membrane technology, etc., can solve the problems of poor adsorption effect, large gas treatment capacity, and physical health effects, and achieves simple design, improved treatment capacity and effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

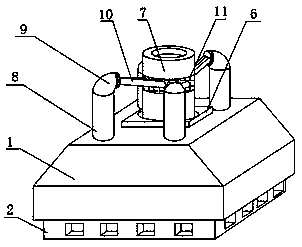

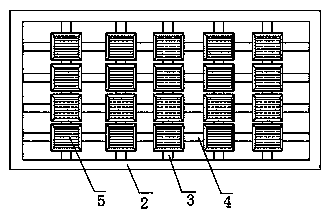

[0019] Such as Figure 1-4 As shown, a high-efficiency degassing structure for a FRP production workshop includes a workshop ceiling 1 and a ventilation unit 2. Rods 3 and four sets of cross bars 4, the joints of the longitudinal bars 3 and the cross bars 4 are fixedly provided with exhaust fans 5, and the exhaust fans 5 are fixed by riveting;

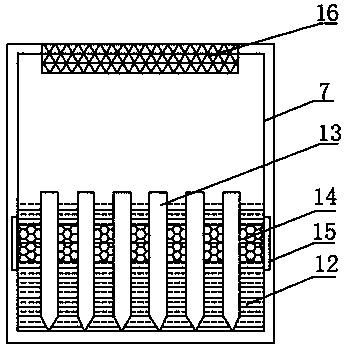

[0020] A base 6 is welded in the middle of the upper end surface of the workshop ceiling 1, and a degassing barrel 7 is fixedly placed on the upper end of the base 6, and air ducts are arranged around the upper end surface of the workshop ceiling 1 close to the degassing barrel 7. 8. The upper end of the air duct 8 is threadedly connected with a three-hole joint 9, and the three-hole joint 9 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com