Dunnage converter support and system thereof

A conversion system and conversion machine technology, applied in the direction of thin material handling, transportation and packaging, spreading thin soft materials, etc., can solve the problems of parts that hinder access to the inside of the machine, complicated installation and setting methods, and harmful effects on the quality of padding products, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

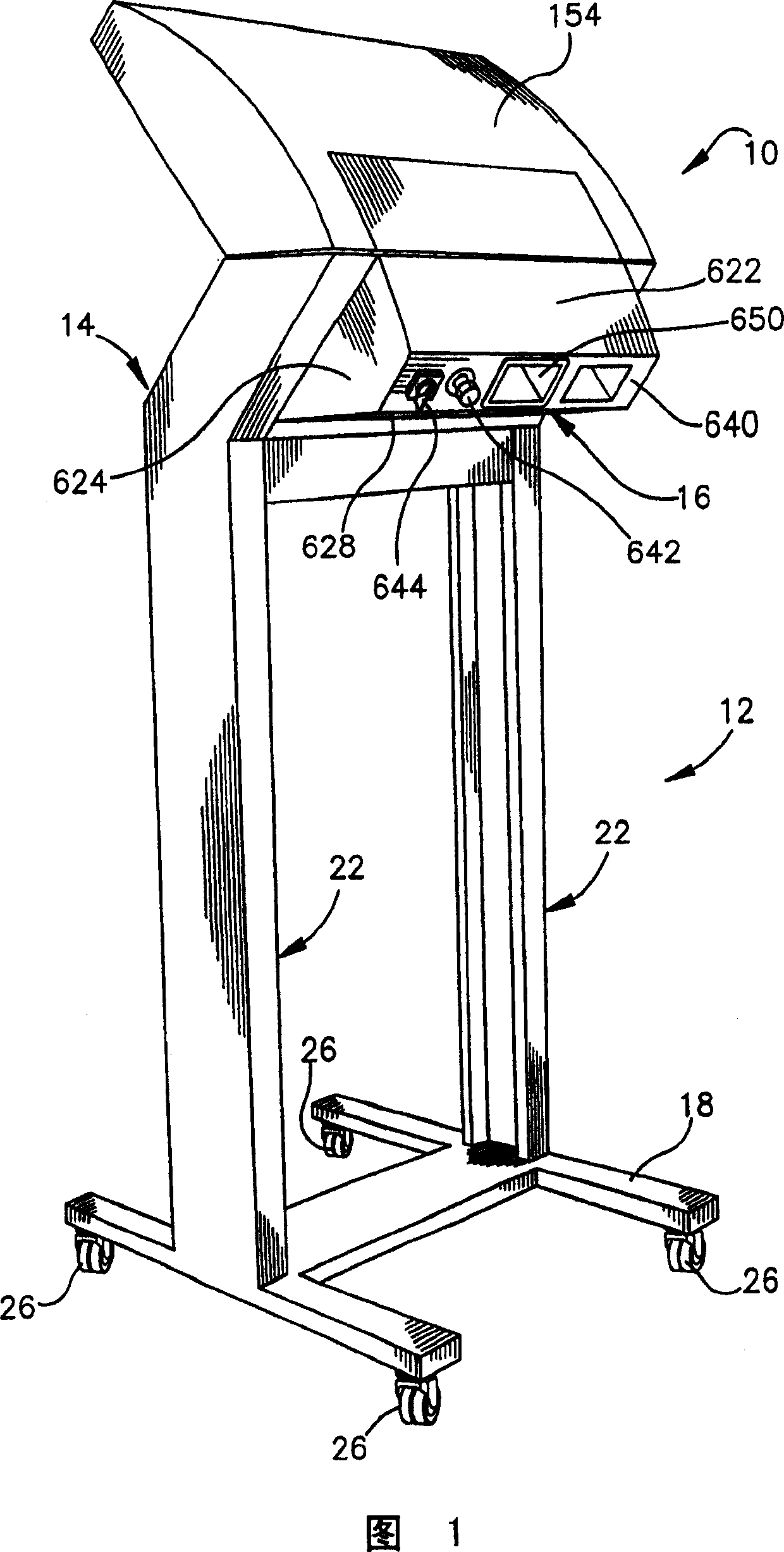

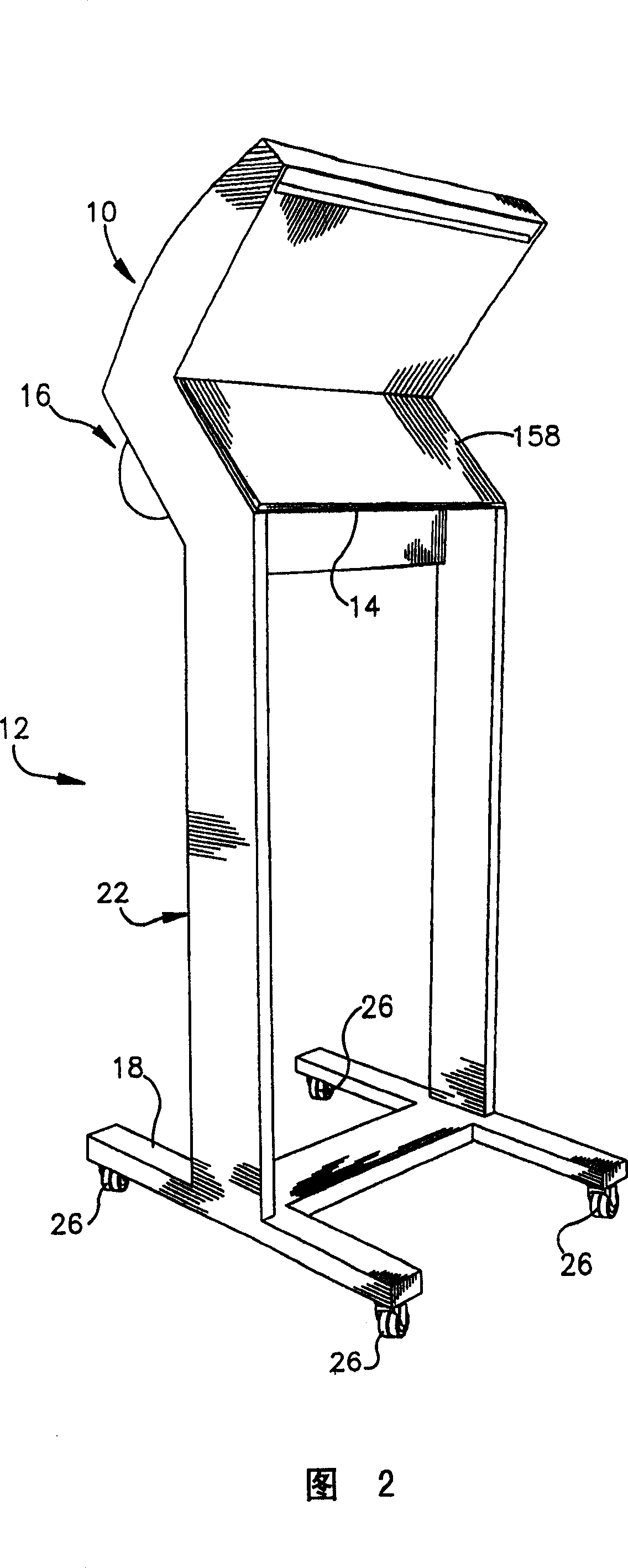

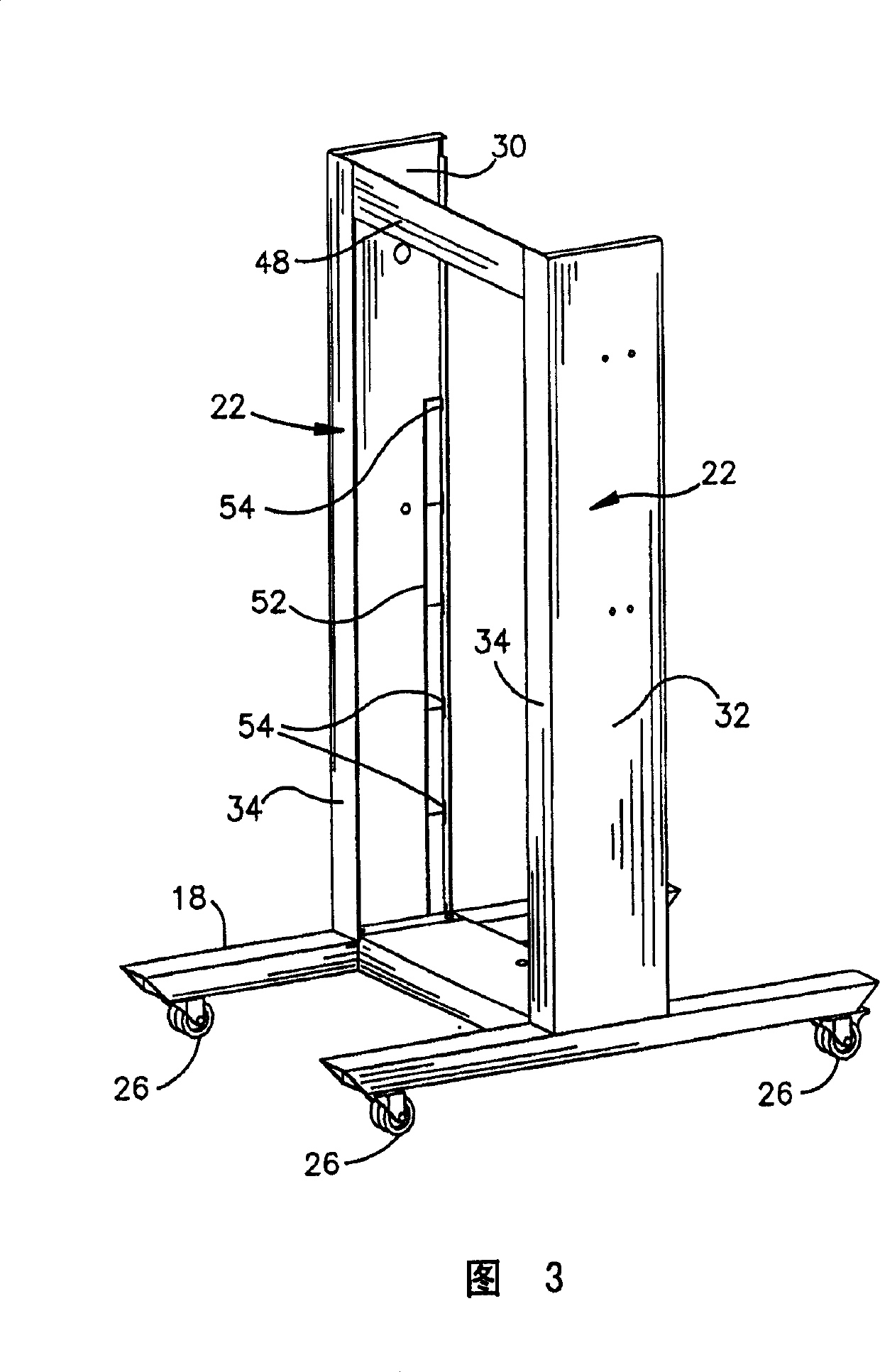

[0090] Referring now to the accompanying drawings in detail, see first Figures 1 to 4 , which shows a dunnage conversion machine 10 and stand 12 according to the present invention. Dunnage conversion machine 10 converts sheet-like stock material, such as one or more layers of recycled and reusable kraft paper, into strips of dunnage comprising, for example, narrower three-dimensional strips or substantially cylindrical strands. Machine 10 has an upstream end 14 at which sheet stock material is supplied to machine 10 and a downstream end 16 at which dunnage product is discharged from machine 10 . As used herein, the terms upstream and downstream refer to the path that the sheet stock travels as it moves from the rack 12 as a strip of dunnage product to the exit of the dunnage conversion machine 10, as shown at 15 ( Figure 8 ). Dunnage products are used as environmentally friendly packaging materials, often as void filler or cushioning during transportation. The stand 12 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com