Roller for plating

A roller and cylindrical technology, applied in the field of electroplating rollers, can solve the problems of size limitation, increase manufacturing cost, lack of versatility, etc., and achieve the effects of preventing catching or falling off, reducing manufacturing cost and improving versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

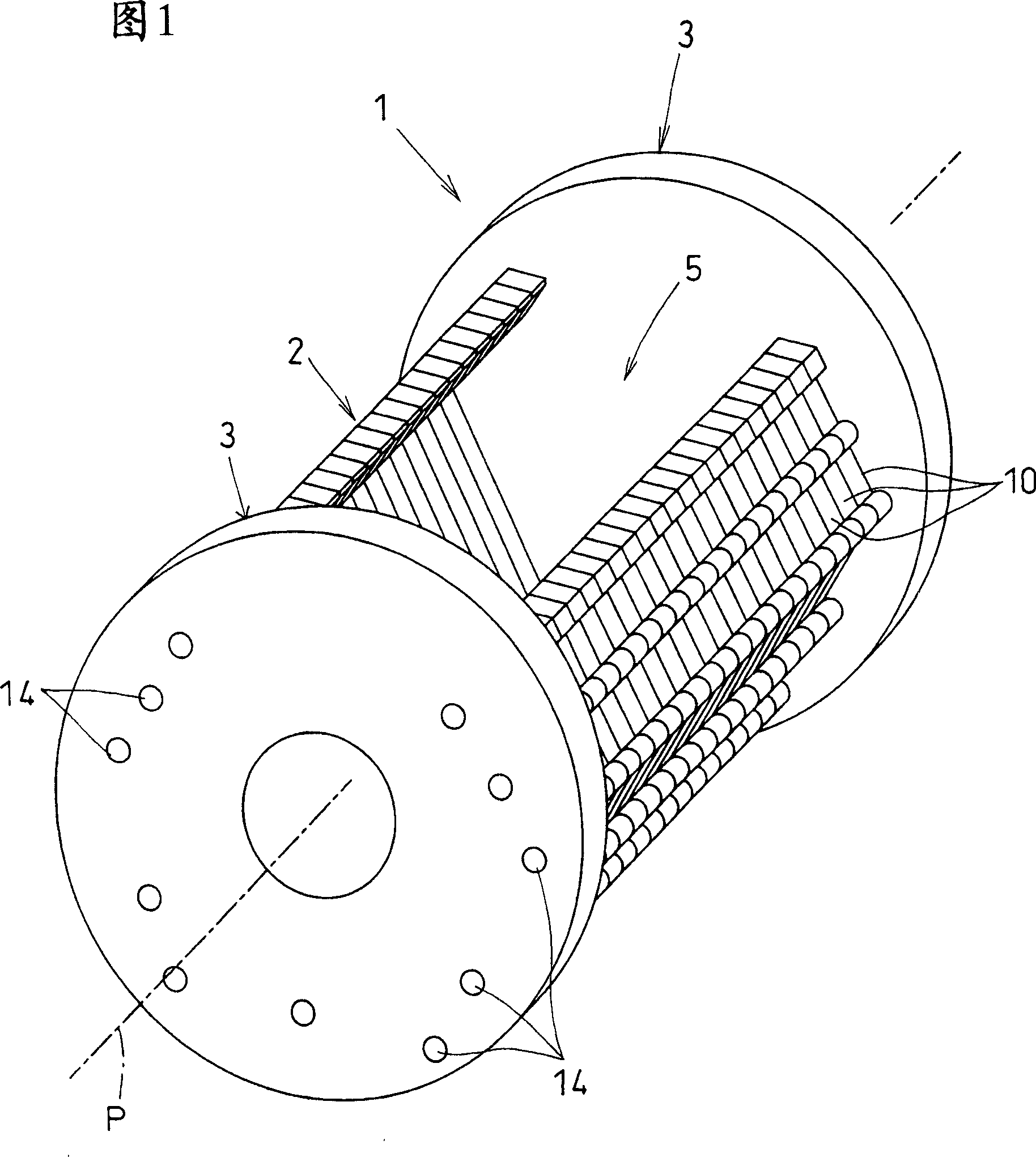

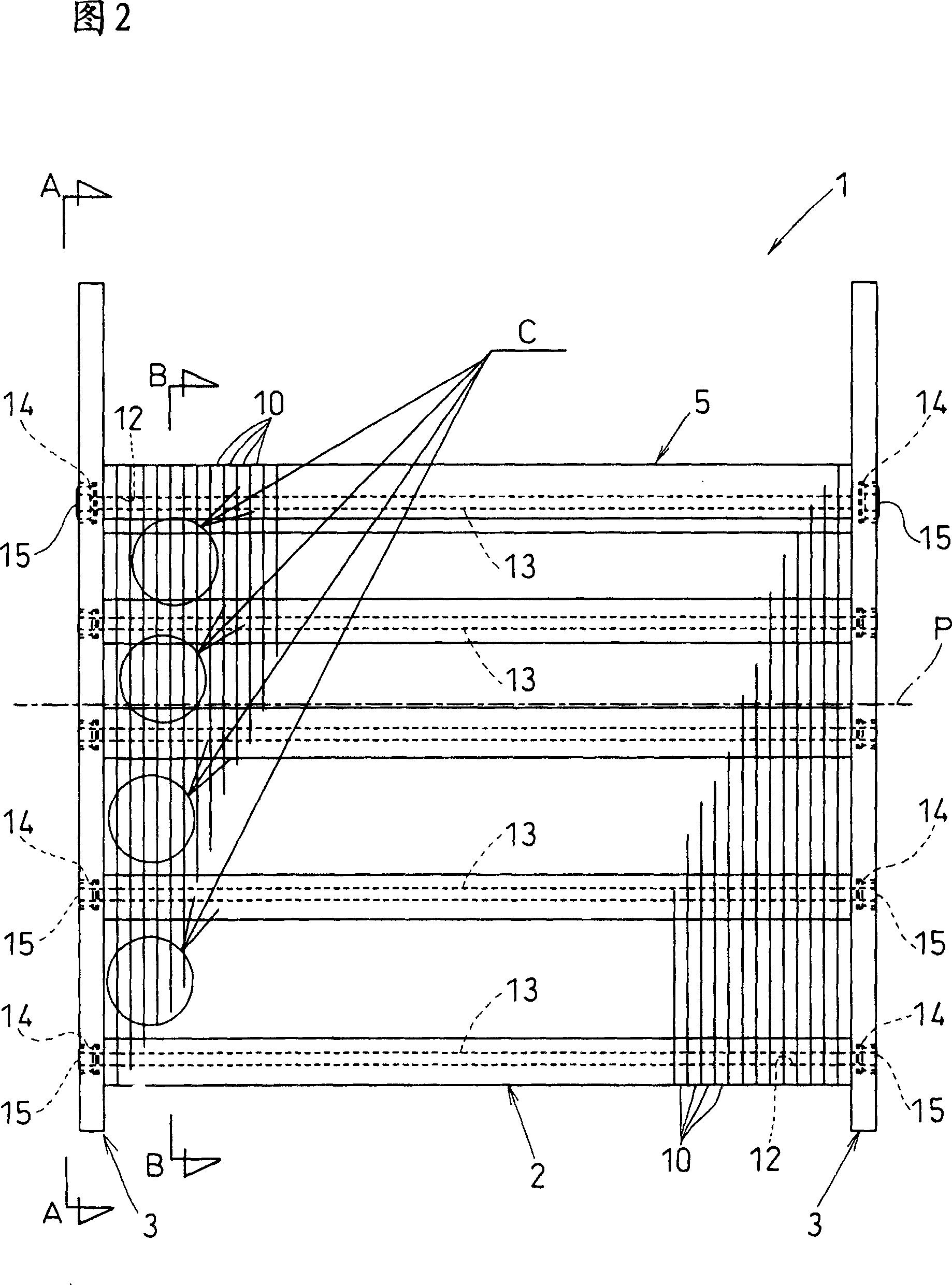

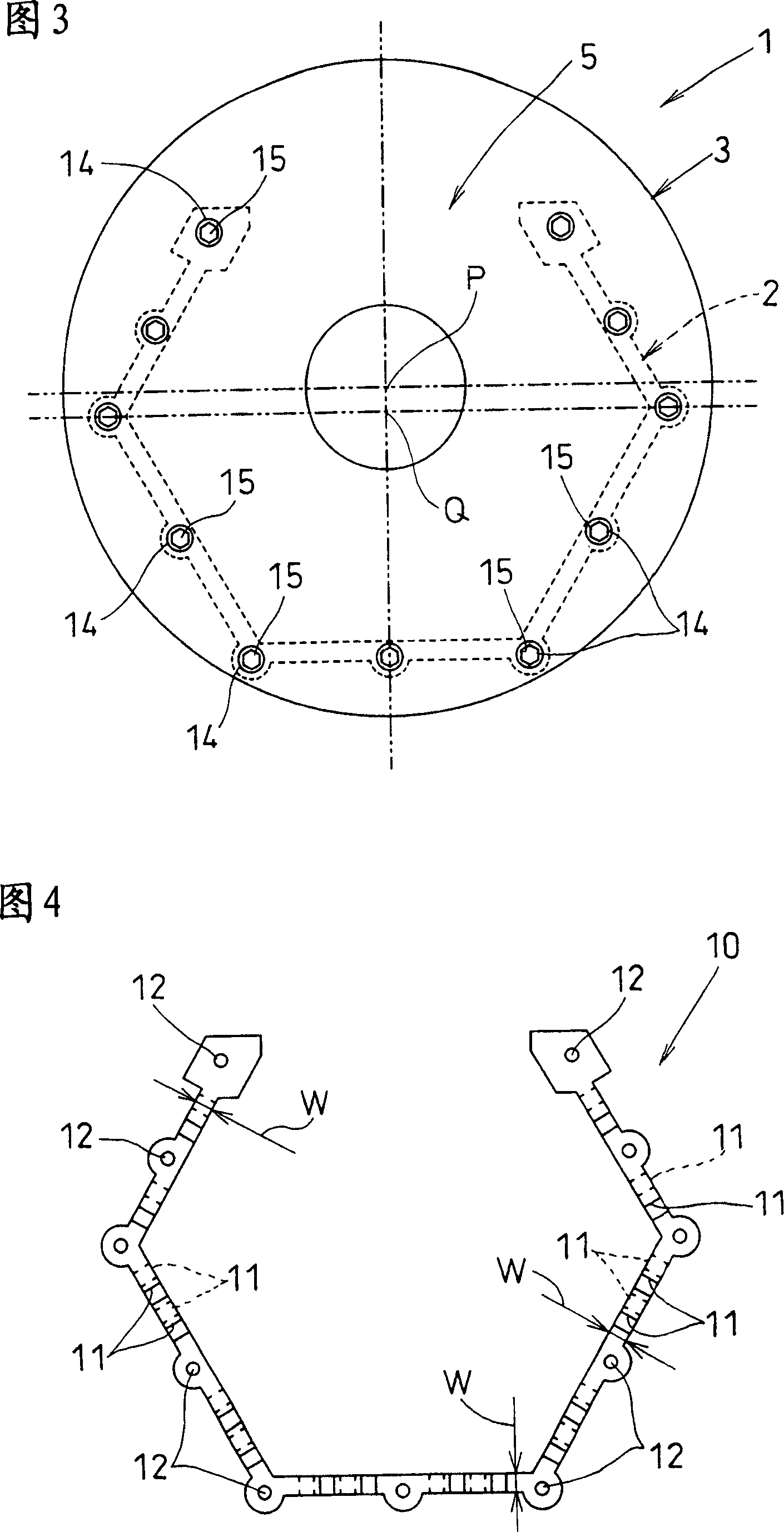

[0032] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0033] 1 to 5 show a first embodiment of a plating drum 1 of the present invention. This drum 1 has a main body 2 and end walls 3 provided at both ends of the main body 2, the main body 2 is formed in a cylindrical shape with both ends open, and the end walls 3 are in a state of closing both ends of the main body 2. Combined with this main body part 2.

[0034] In this embodiment, the main body portion 2 is formed into a hollow regular hexagonal square tube in cross-section, and the workpiece to be plated is placed here in a state where one side (a side surface imitating a regular hexagon) is removed. Port 5.

[0035] The workpiece to be plated can be accommodated or taken out from the cavity formed inside the main body 2 (the range surrounding both ends by the end wall 3 ) through the workpiece opening 5 . During plating, a resin cover (not shown) is attached to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com