Traction engine data transmitting system

A technology of transmission system and tractor, applied in the field of tractor data transmission system, can solve problems such as increased cost, non-action of tractor, and increase in the number of slip-out lines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

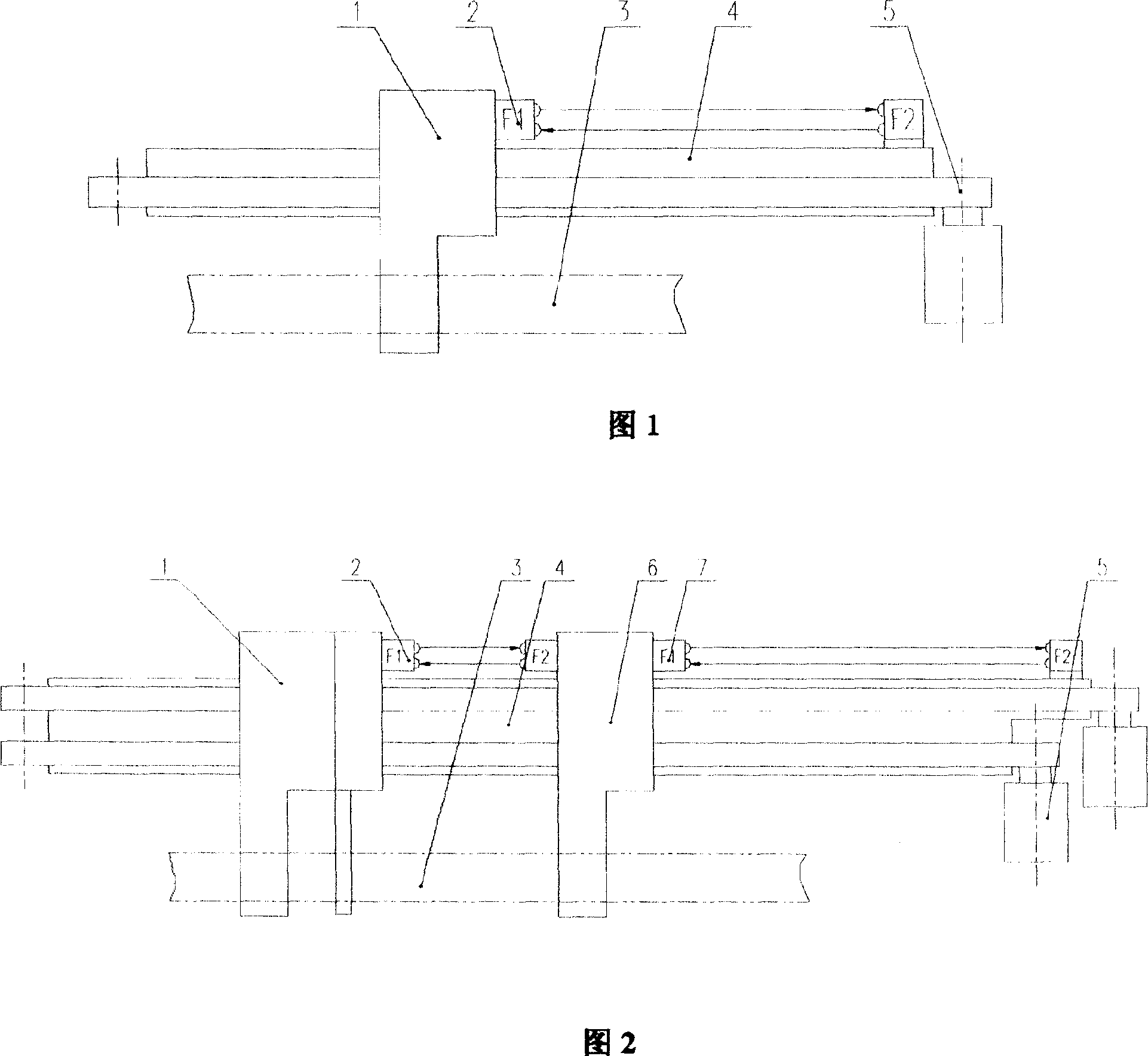

[0016] As shown in Figure 1, for a single tractor, the tractor guide rail 4 is arranged on the frame, and No. I tractor head 1 is slidably connected on the tractor guide rail 4, and No. I tractor head 1 is vertically arranged on the traction machine. On the tractor guide rail 4, the aluminum profile 3 is connected below No. I tractor head 1; one end of the tractor guide rail 4 is connected with the tractor driving device 5; the frame is provided with a data transmission photoelectric sensor, and the data transmission photoelectric sensor has two The first pair of data transmission photoelectric sensors 2 are installed on the right side above the active tractor nose 1, move together with the tractor nose 1, and are electrically connected to the distribution station on the tractor nose 1; the other The second pair of data transmission photoelectric sensors 7 are fixed above one end of the tractor guide rail 4, and are electrically connected with the central processing unit PLC of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com