Making process of ancient wood furniture and door with weathering effect

A manufacturing method and solid wood technology, applied in the field of solid wood door manufacturing and solid wood furniture, can solve the problems of easy fading and unnatural antique effect, and achieve remarkable effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Take the solid wood door as an example below to further illustrate the present invention

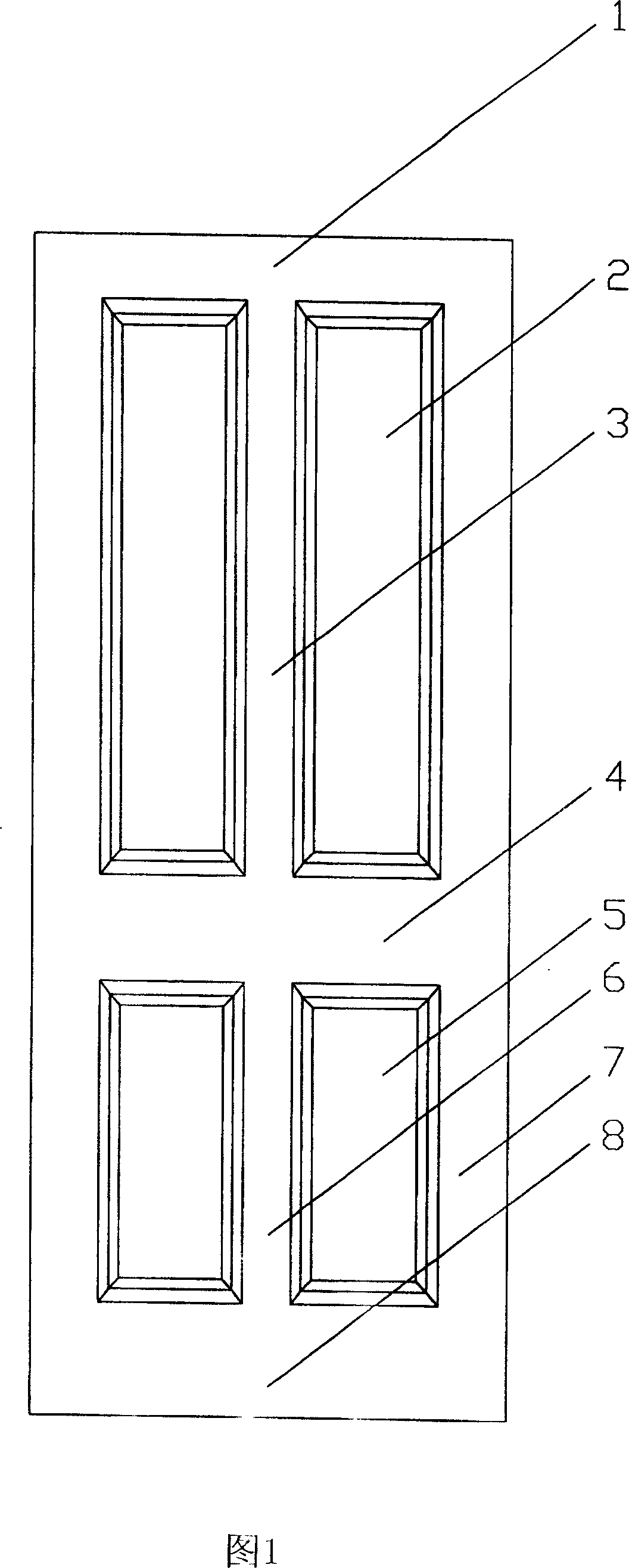

[0021] As shown in Figure 1, solid wood door has comprised upper and lower pool plate 2,5, upper, middle and lower cross frame 1,4,8, upper and lower vertical frame 3,6, components such as side frame 7. First of all, the components of the solid wood door are made according to the specifications, and then the whole upper and lower pool panels 2 and 5 are contacted with a high-temperature flame of 800-1100°C before assembly. The best temperature is 1000°C. ~ Burn quickly and evenly within 1.2 seconds, preferably 1 second, and then use a wire brush to rub the entire solid wood pool board to wipe off the carbonized cork attached to the surface, so that the high temperature resistant part has not been burned The wood grain part is naturally highlighted, and then it is integrally assembled with other components, and after being assembled into a finished product as shown in Figure 1, oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com