Liquid aqueous multi-color granite coating and preparation method thereof

A granite coating, water-based technology, applied in the coating and other directions, can solve the problems of easy breakage, serious thickening, and high viscosity of construction color particles, and achieve the effect of clear color particles, strong self-cleaning function, and natural and smooth texture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

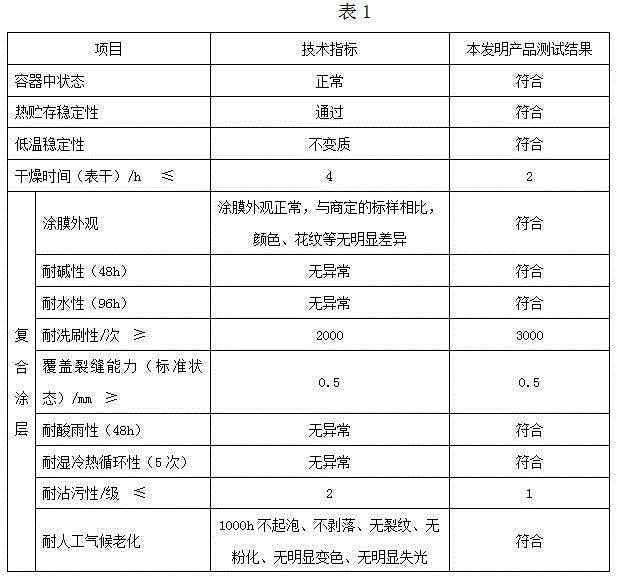

Examples

Embodiment 1

[0026] 1. Prepare 7% G-30 protective glue: add 279.0kg of water into the equipment, start stirring, slowly add 21.0kg of G-30 protective glue, and stir at 1200 rpm for 30 minutes;

[0027] 2. Prepare the base paint: Add 165.0kg of water, 1.2kg of Nopco SN-NXZ defoamer, 0.9kg of Rohm and Haas LXE preservative and 0.9kg of Shanghai Yiyou A-4 wetting and dispersing agent into the equipment in sequence, Start stirring, disperse at 800 rpm for 10 minutes, then slowly add 4.5kg of Wuxi Haopu R-2196 rutile titanium dioxide and 57.0kg of Inner Mongolia Mengxi superfine calcined kaolin, disperse at 1200 rpm for 20 minutes, and then add Shanghai Yiyou Q-25 special resin thickener 7.5kg and camine328 multifunctional pH regulator 0.3kg, disperse for 30min, finally add BATF 2788 elastic emulsion 54.0kg and 7%G-30 protective glue 8.7kg, disperse 5min;

[0028] 3. Preparation of colorful particles: according to the needs, the iron oxide-based color paste in the base paint prepared in step 2...

Embodiment 2

[0031] 1. Prepare 7% G-30 protective glue: add 297.6kg of water into the equipment, start stirring, slowly add 22.4kg of G-30 protective glue, and stir at 1200 rpm for 30 minutes;

[0032] 2. Prepare the base paint: Add 159.0kg of water, 0.9kg of BYK-024 defoamer, 0.6kg of Deqian MB-11 preservative and 1.5kg of Shanghai Zecheng EML-7383 wetting agent into the equipment, and start stirring , disperse at 700 rpm for 5 minutes, then slowly add 3.0kg of Wuxi Haopu R-2196 rutile titanium dioxide and 51.0kg of Inner Mongolia Mengxi superfine calcined kaolin in turn, disperse at 1100 rpm for 15 minutes, and then add Shanghai Yiyou 6.0kg of Q-25 special resin thickener and 0.6kg of Dow AMP-95pH regulator, disperse for 25 minutes, and finally add 66.0kg of BATF 2788 elastic emulsion and 11.4kg of 7% G-30 protective glue, and disperse for 5 minutes;

[0033] 3. Prepare colorful particles: add phthalocyanine color paste to the base paint prepared in step 2 as needed to prepare the base p...

Embodiment 3

[0036] 1. Prepare 7% G-30 protective glue: add 372.0kg of water into the equipment, start stirring, slowly add 28.0kg of G-30 protective glue, and stir at 1200 rpm for 30 minutes;

[0037] 2. Prepare the base paint: Add 228.0kg of water, 0.8kg of BYK-033 defoamer, 0.4kg of Deqian MB-16 preservative and 1.6kg of Dow X-405 wetting agent into the equipment in sequence, start stirring, Disperse at 900 rpm for 15 minutes, then slowly add 8.0kg of Wuxi Haopu R-2196 rutile titanium dioxide and 60.0kg of superfine calcined kaolin from Inner Mongolia Mengxi in sequence, disperse at 1300 rpm for 25 minutes, and then add Shanghai Yiyou Q -25 special resin thickener 12.0kg and Deqian DMAE water-based amine neutralizer 1.2kg, disperse for 35 minutes, finally add BATF 2788 elastic emulsion 80.0kg and 7% G-30 protective glue 8.0kg, disperse for 10 minutes;

[0038] 3. Prepare colorful particles: Add iron oxide color paste to the base paint prepared in step 2 as needed to prepare base paints ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com