Control device for double-layer loading pot in mine shaft

It is a technology for upper-level truck operation and mine shafts, which is applied to lifting equipment, transportation and packaging, and earthwork drilling and mining in mines. It can solve the problems of reduced space, low lifting efficiency, and long rest time of secondary sinking tanks, etc., to achieve reduced space. , improve efficiency, and solve the effect of undertaking problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

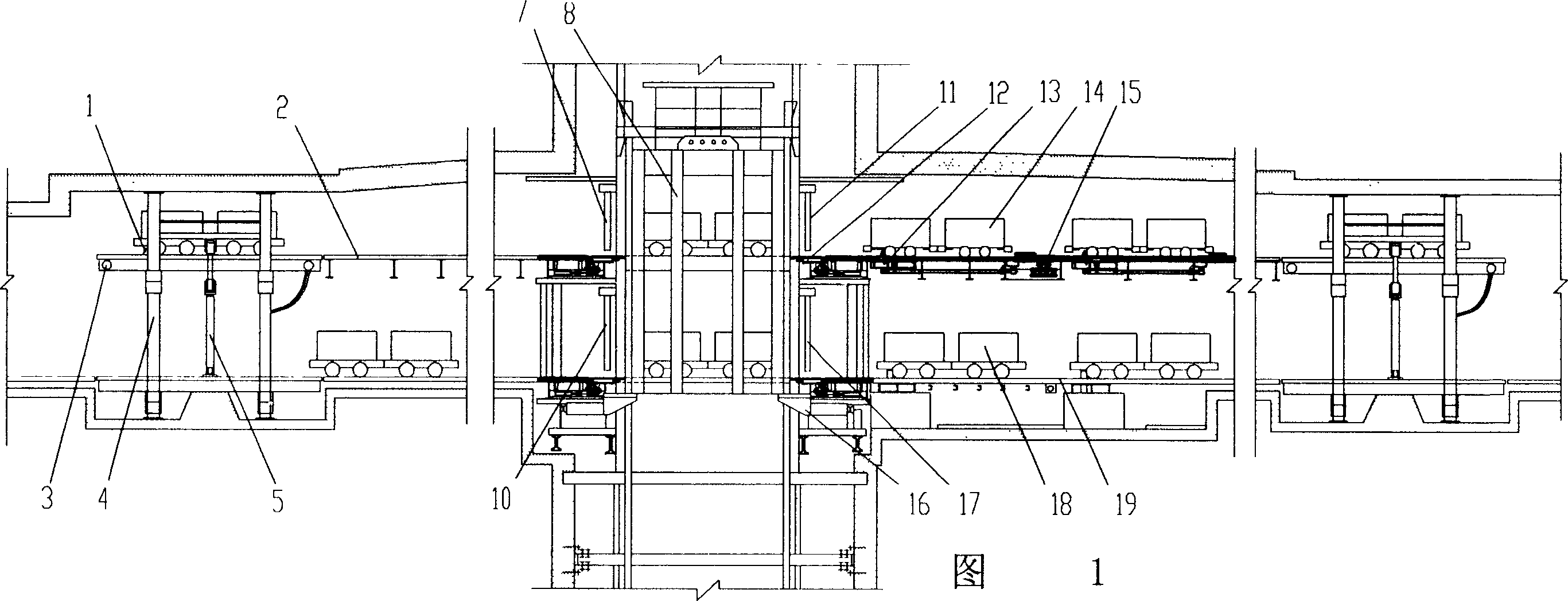

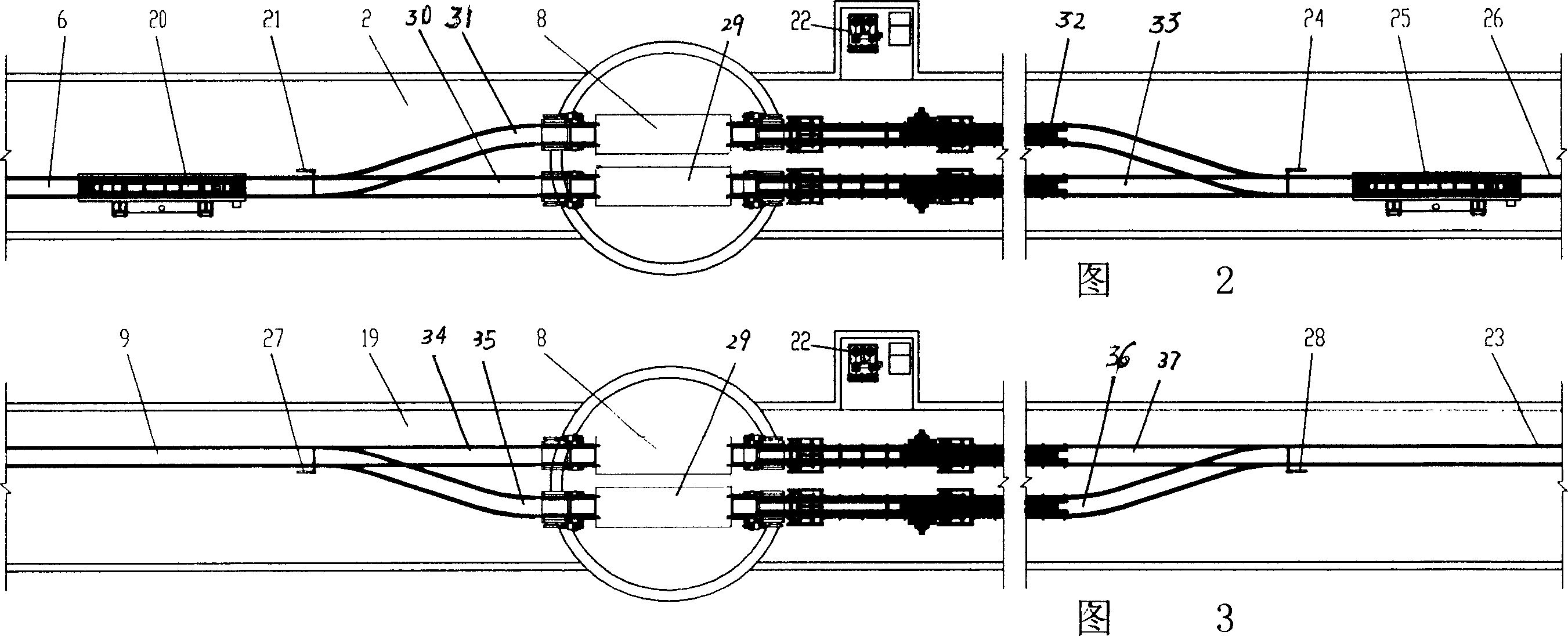

[0010] The wellhead is equipped with a hoisting winch, an upper-level car-operating platform and a lower-level car-operating platform. The hoisting winch is connected to the front and rear cages 8, 29 through wire ropes and connecting devices. The front and rear cages 8, 29 alternate up and down in the mine, and the front cage 8 is in the When loading and unloading at the bottom of the well, the rear cage 29 can be loaded and unloaded just at the well head. The front and rear cages 8, 29 have two levels, each level has two parking spaces for mine cars, and each of the upper and lower floors corresponds to each parking space for mine cars. One minecart rail line and four minecart rail lines are respectively laid on the upper car operating platform 2 and the lower car operating platform 19. Figure 1 shows the structure diagram of the upper and lower car operating platforms installed at the horse head gate at the bottom of the shaft. The front mine car track lines 31 and 32 of the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com