Glass plate pressure defoaming machine

A pressurized defoaming and glass substrate technology, which is applied in the field of defoaming devices, can solve problems such as support mechanism breakage, achieve the effects of volume reduction, shortening process time, and avoiding uneven configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

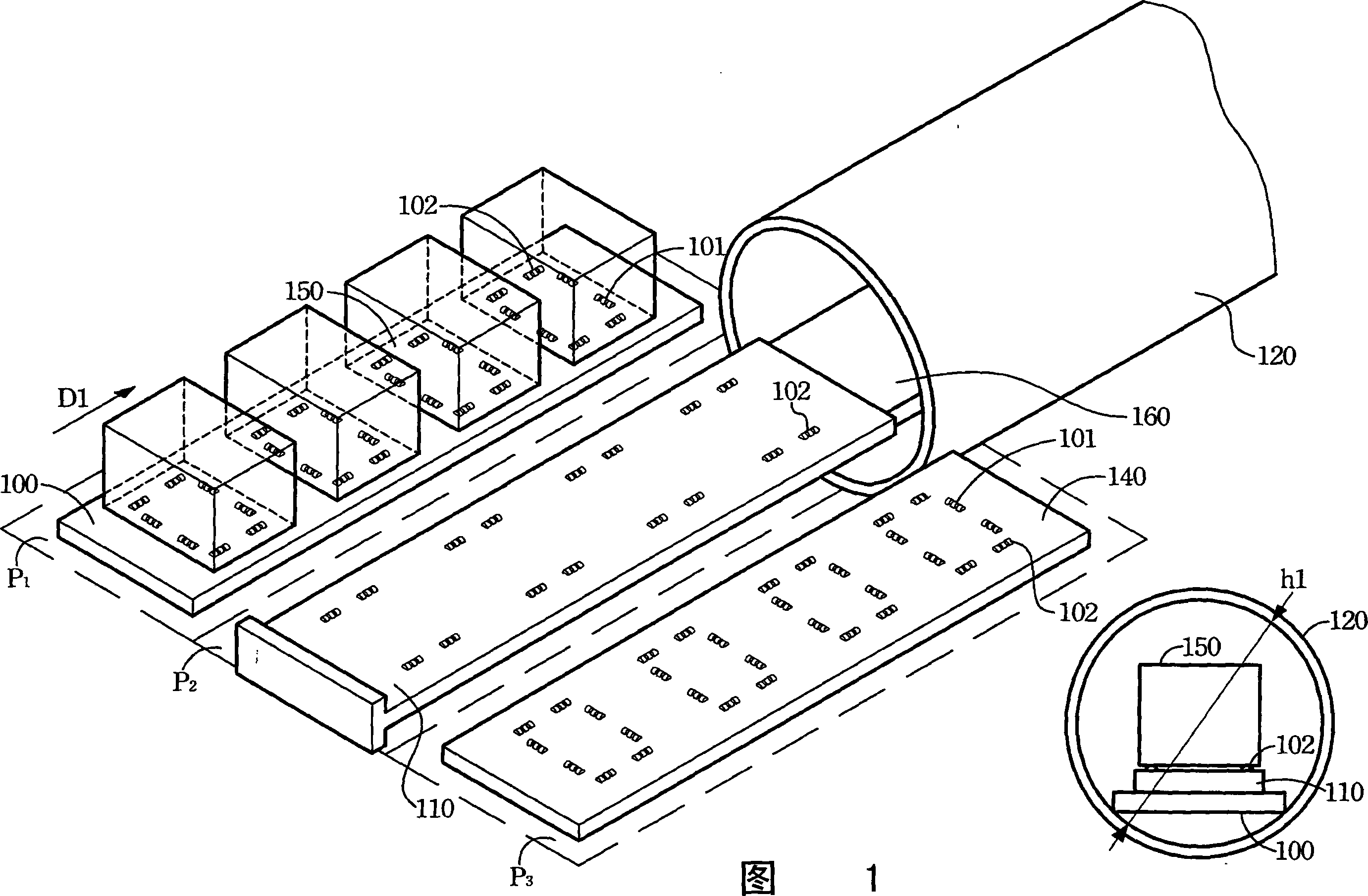

[0028] The invention relates to a degassing device for a glass substrate. The defoaming device of the present invention can improve the efficiency of the defoaming operation, and can solve related problems such as breakage of the support mechanism caused by the overweight cassette. A detailed description of the present invention is as follows.

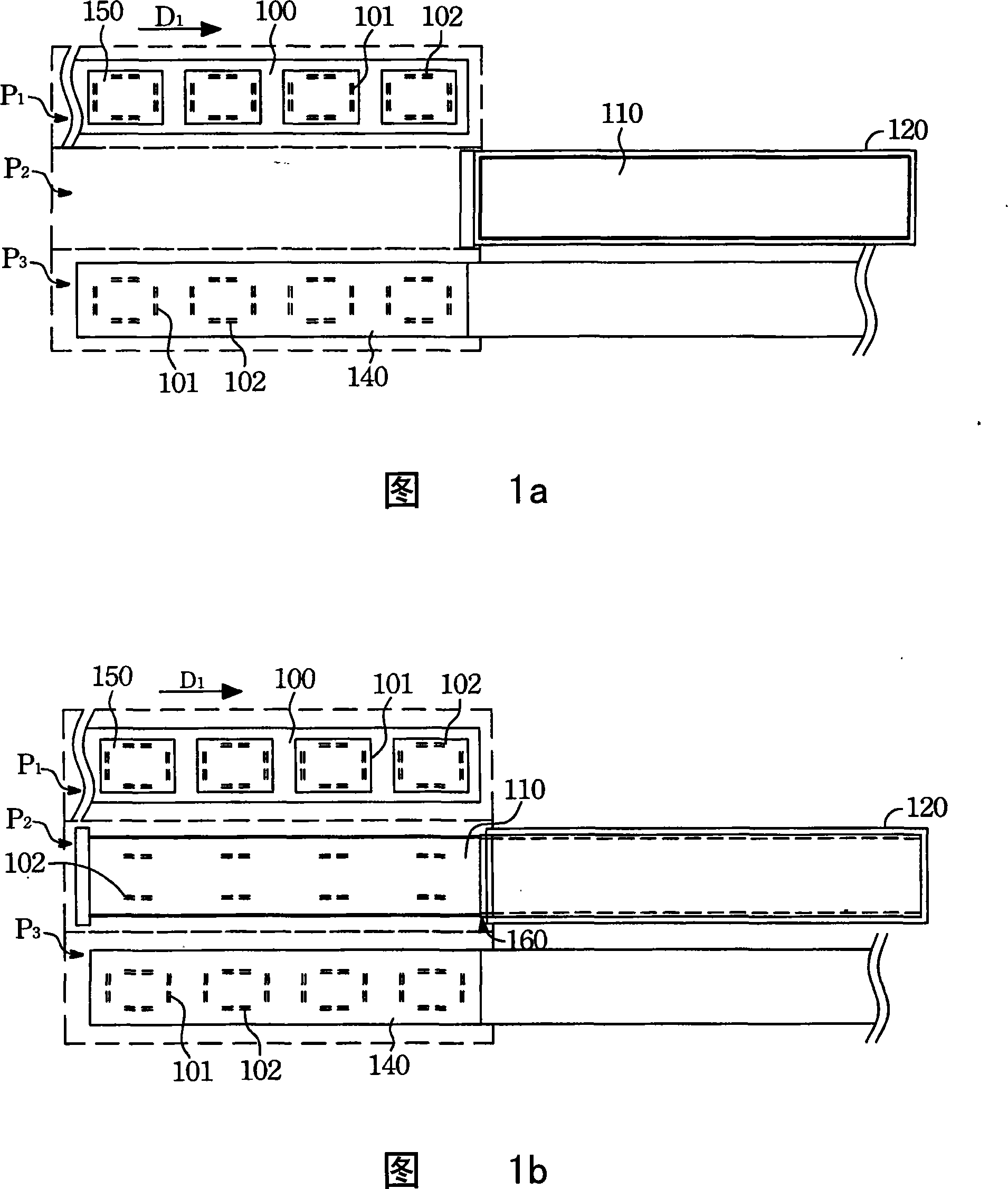

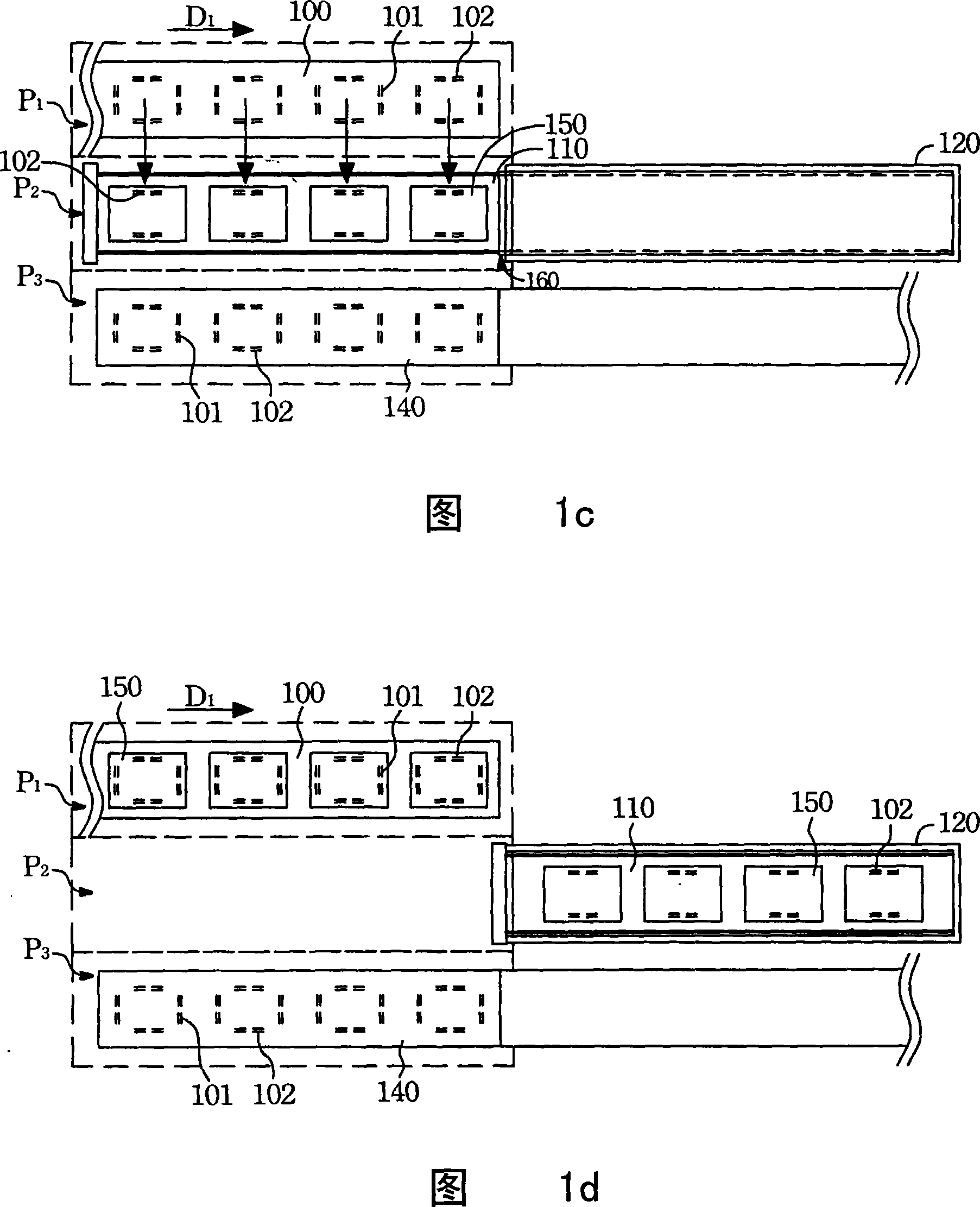

[0029] Please refer to FIG. 2 , which is an appearance view of the degassing device of the present invention. The degassing device of the present invention includes a degassing reaction furnace 220 , a loading platform 200 and an unloading platform 240 . The defoaming reaction furnace 220 has a furnace mouth, a slide table 210 is arranged inside the furnace mouth, and a furnace door 280 is arranged outside the furnace mouth. The sliding table 210 is provided with a plurality of first direction transmission wheels 201 . The carrying platform 200 reciprocates between the first position P1 and the second position P2, and the carrying p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com