Cast-in-place concrete hollow core slab

A hollow slab, cast-in-place concrete technology, applied in the direction of floor slabs, building components, buildings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

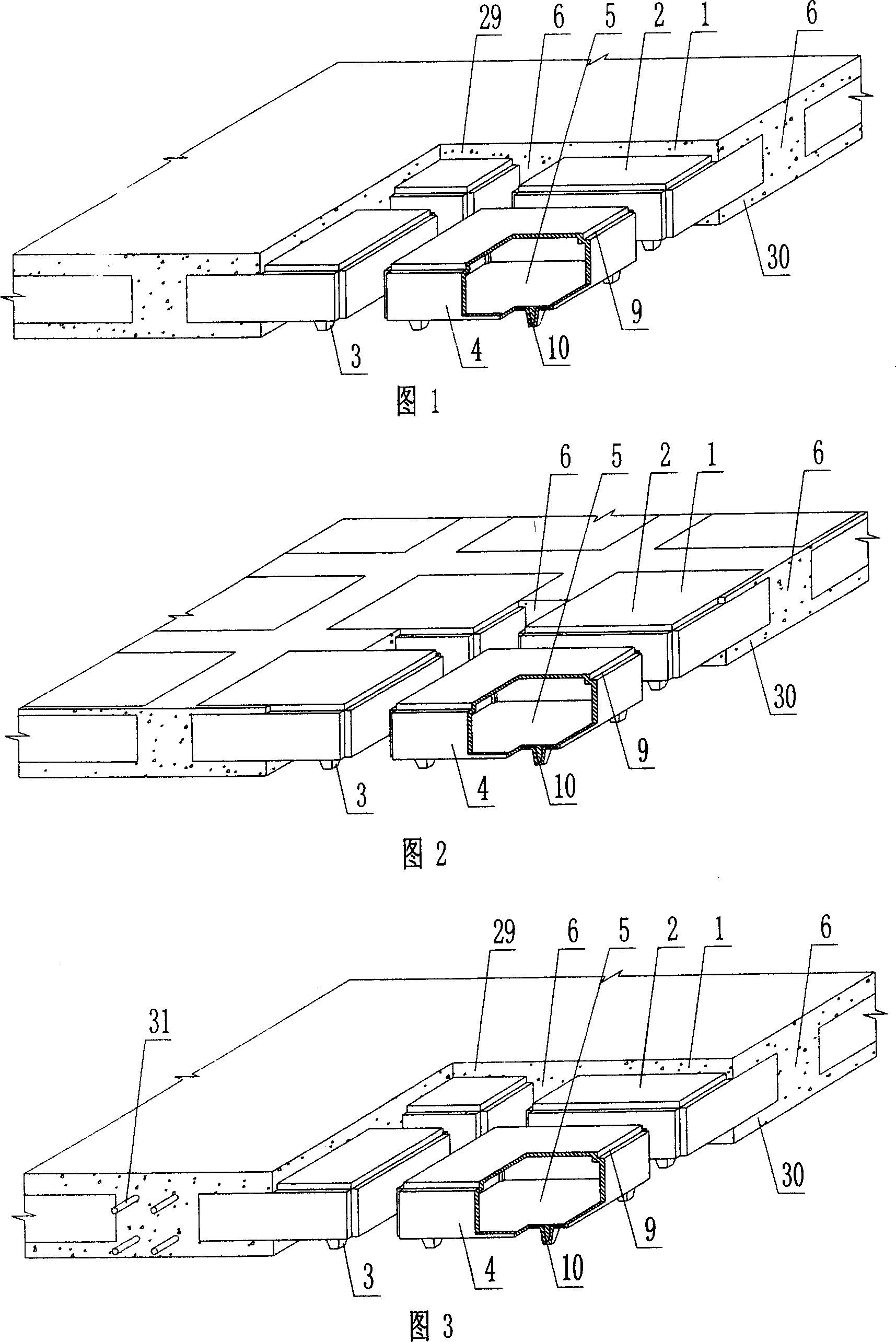

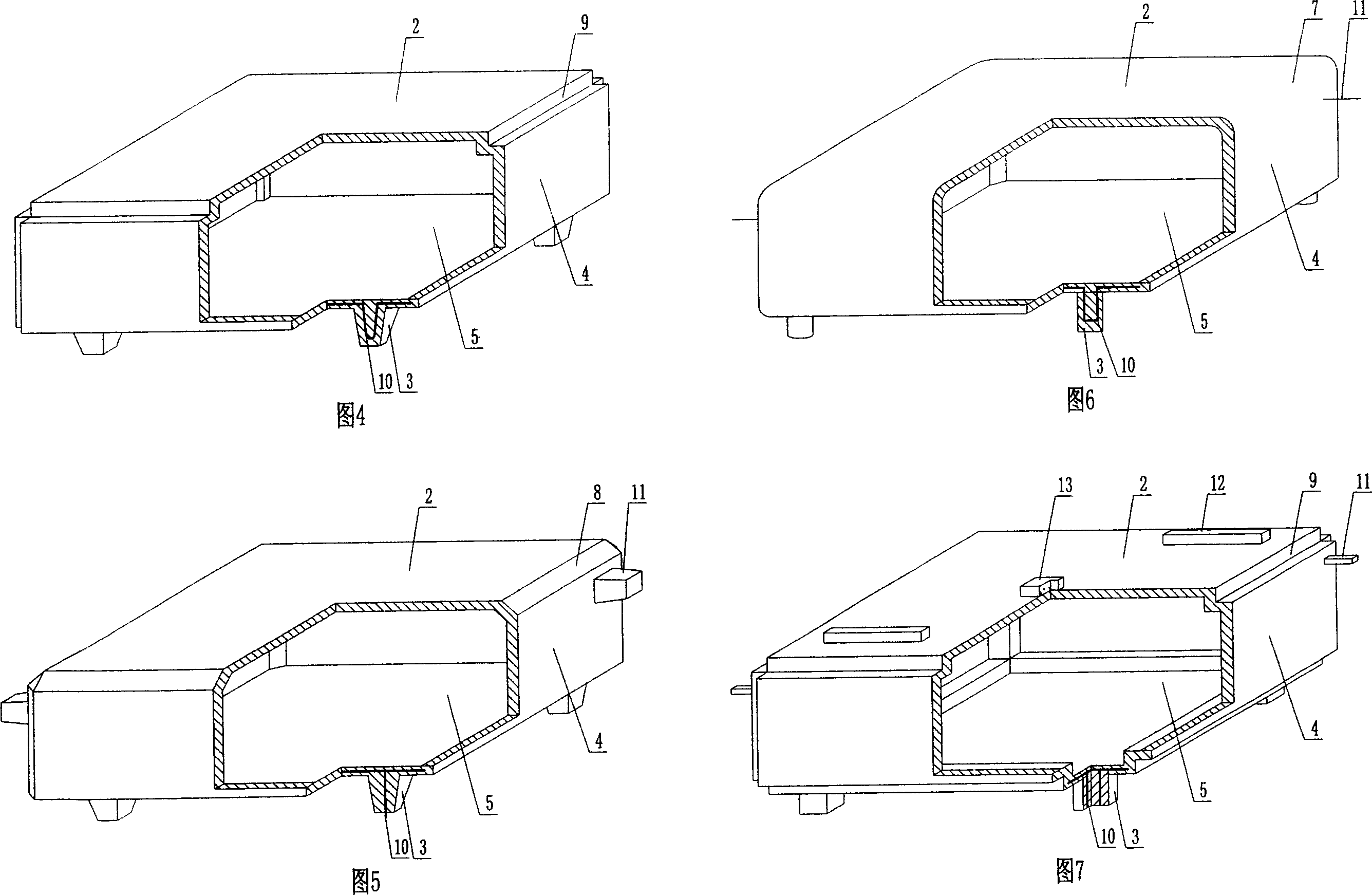

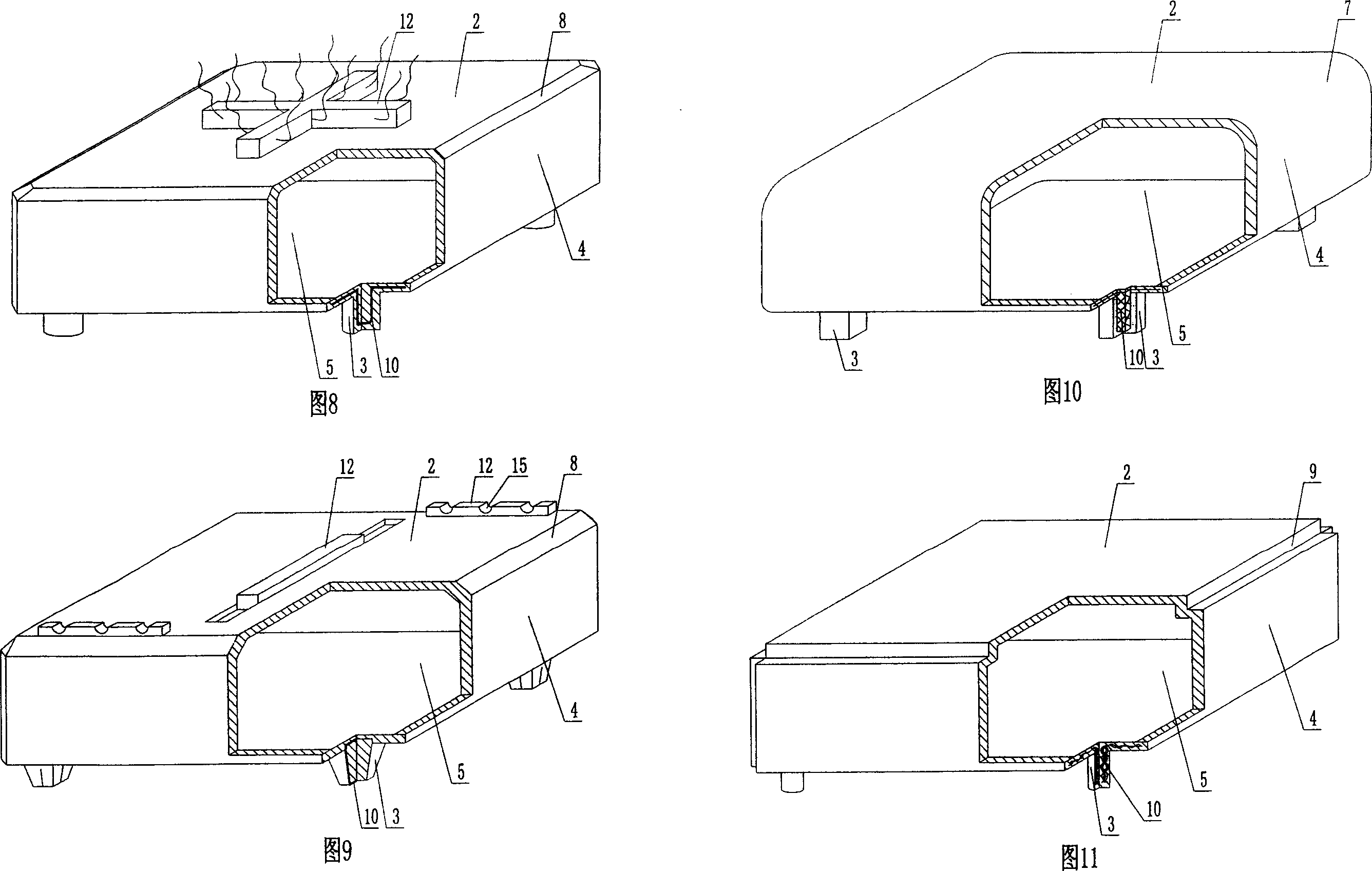

[0074] Below in conjunction with accompanying drawing and embodiment the present invention will be further described

[0075] As shown in the accompanying drawings, the present invention includes a reinforced concrete 1 and a hollow carcass 2, the hollow carcass 2 is wrapped in the reinforced concrete 1, the bottom outer wall 4 of the hollow carcass 2 is provided with a support foot 3, and the outer wall 4 is enclosed to form A hollow carcass 2 with a cavity 5, and the cast-in-place reinforced concrete ribs 6 formed by the reinforced concrete 1 between the hollow carcass 2 are characterized in that the intersecting corners of at least two adjacent surfaces of the hollow carcass 2 It is at least one of the arc corner 7, the chamfer 8 or the inner corner 9, and the anti-collision tie rib 10 is arranged in the support foot 3, and is anchored in the support foot 3 and the outer wall 4 at the same time. In each attached drawing, 1 is reinforced concrete, 2 is hollow carcass, 3 is s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap