Partial load enabled falling film evaporator and method for operating a partial load

A technology of falling film evaporator and steam, which is applied in the direction of chemical instruments and methods, separation methods, vertical tube evaporators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

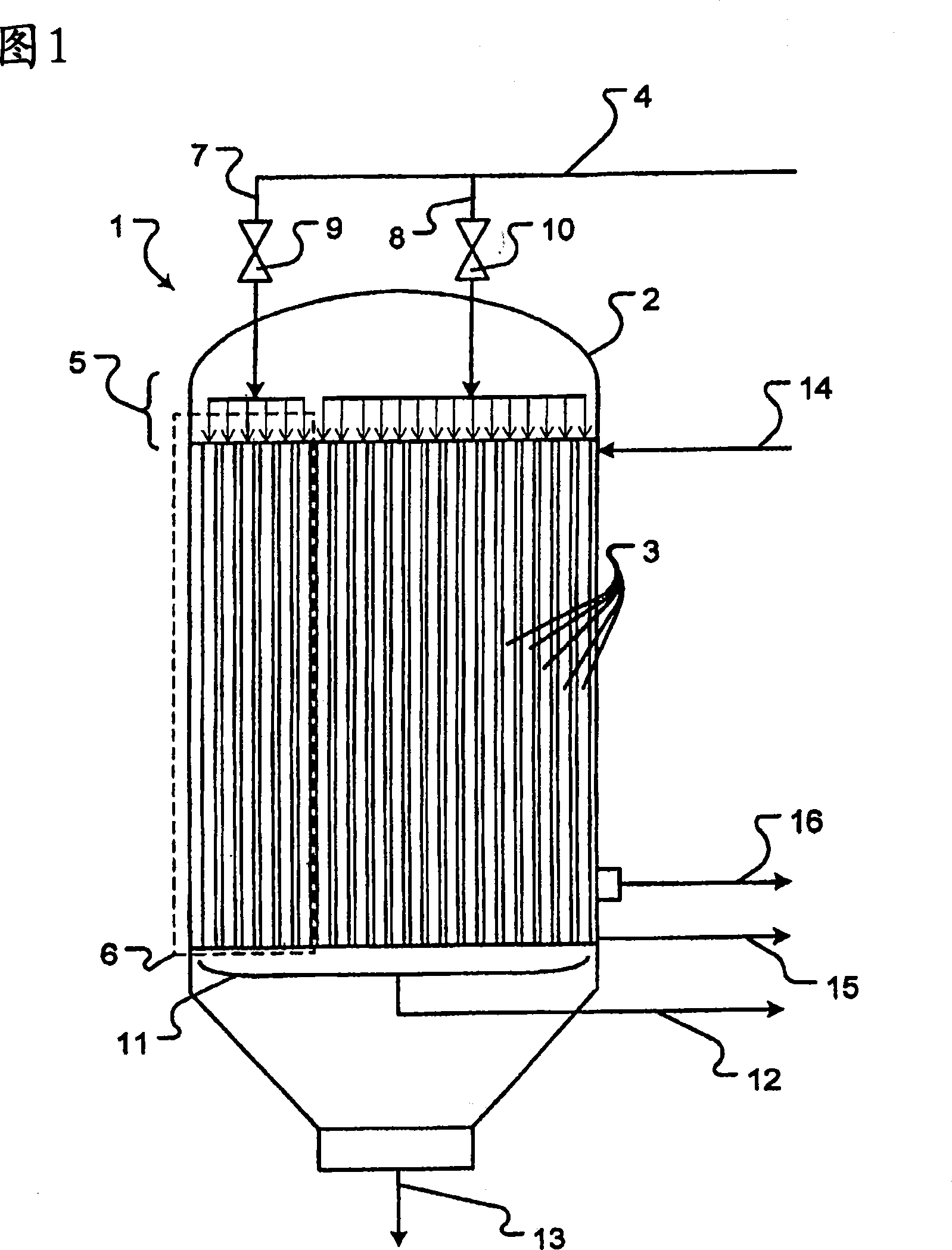

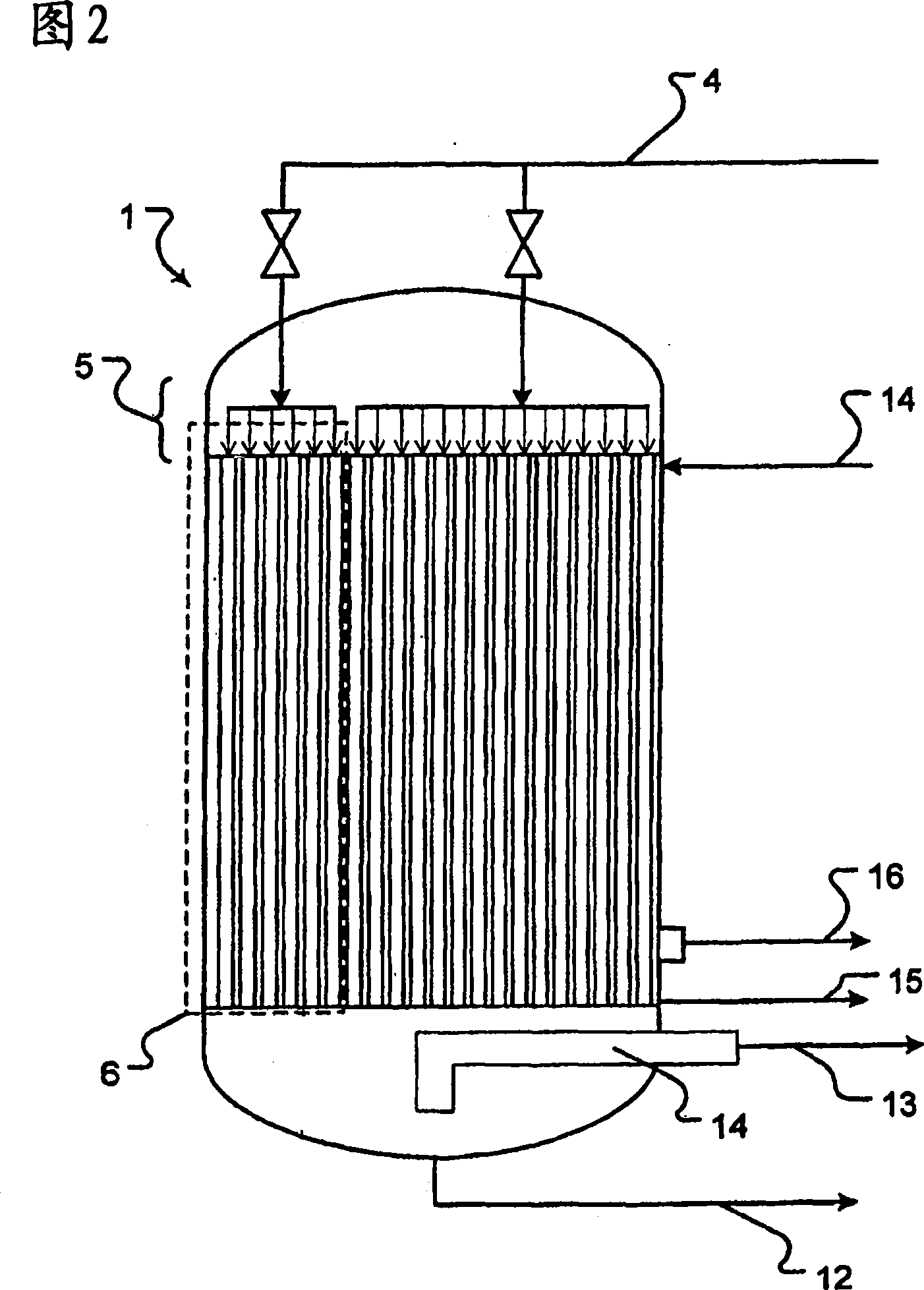

[0035] FIG. 1 shows a falling-film evaporator 1 with a surrounding casing 2 and a plurality of tubes 3 which are fastened at both ends in tube bases which are not shown in detail. The liquid in the feed line 3 is fed via the line 4 to the upper distribution device 5 and distributed via it to the two pipe sections, the smaller pipe section 6 being indicated by the dashed box. Line 4 is divided into two lines 7 and 8 according to the number of sections of distribution device 5 , wherein a valve 9 or 10 is provided in each of lines 7 and 8 so that the sections of distribution device 5 can be separated hydrodynamically from one another.

[0036] A collecting device 11 is arranged below the tube 3 , which receives the residual liquid from the tube 3 and leads it out of the falling film evaporator 1 through a line 12 . The vapors and gases flowing through the tubes 3 or formed there are discharged from the falling-film evaporator 1 via a line 13 .

[0037] The gas-vapor mixture is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com