A reverberatory furnace for sacrificial anode production

A technology of sacrificial anodes and reverberatory furnaces, applied in furnaces, crucible furnaces, furnace types, etc., can solve the problems of increasing the production cost of sacrificial anodes, increasing metal oxidation loss, and reducing economic benefits, so as to reduce the probability of being oxidized and suppress smoke Gas generation, the effect of improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

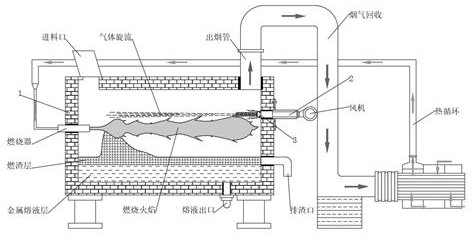

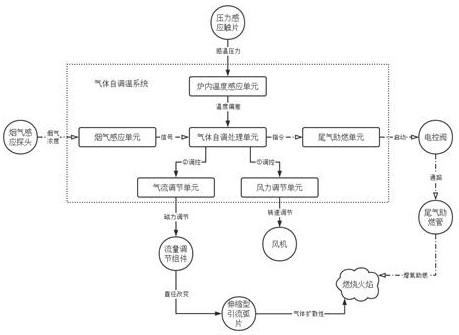

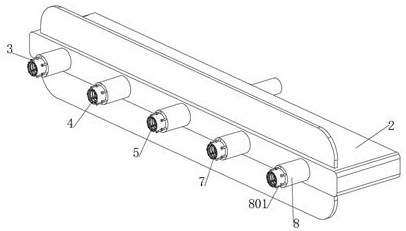

[0044] see Figure 1-10 , a reverberatory furnace for sacrificial anode production, including a protected reverberatory furnace 1, the left end of the protected reverberatory furnace 1 is fixed with a diversion control gas plate 2 through expansion bolts, and the left end of the diversion control gas plate 2 is connected to the fan through a transfer pipe The right end of the diversion control gas plate 2 is fixedly connected with a plurality of airflow restriction pipes 3 connected thereto, the left side of the inner wall of the airflow restriction pipe 3 is fixedly connected with an adjustment limit ring 402, and the right end of the adjustment limit ring 402 is fixedly connected with a plurality of telescopic type drainage arc 4, the right end of telescopic drainage arc 4 is fixedly connected with an adjustment induction coil 403, and the adjustment induction coil 403 is slidingly connected with the airflow restriction tube 3, and the side of the telescopic drainage arc shee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com