Technology for machining contrate tooth profile

A technology of end face tooth shape and processing technology, which is applied to components with teeth, metal processing equipment, gear teeth, etc., can solve the problems of low efficiency, low surface roughness, poor tooth shape accuracy, etc., and achieve high efficiency and parameter accuracy. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

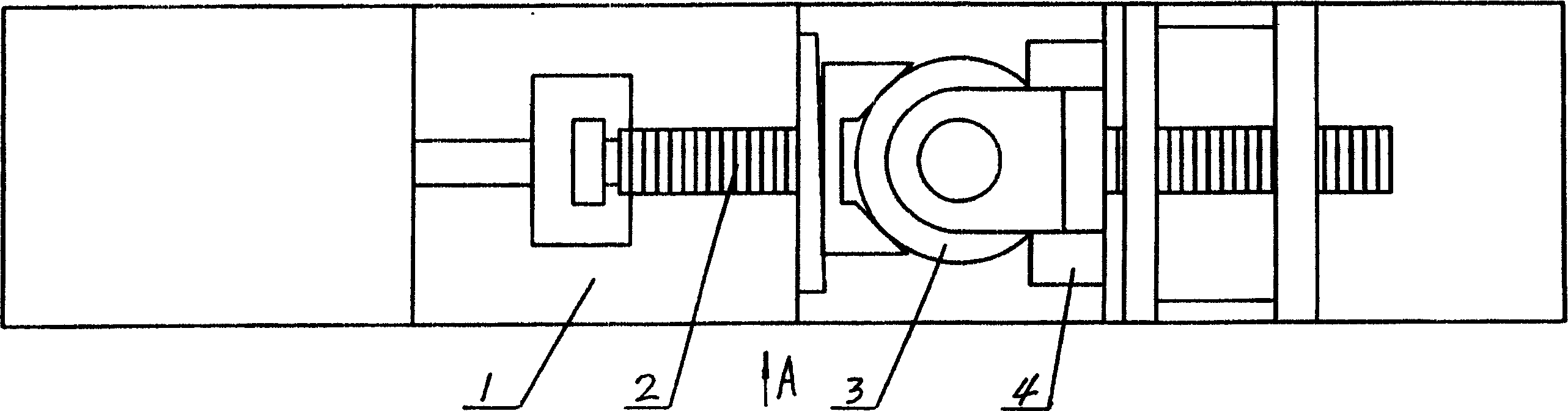

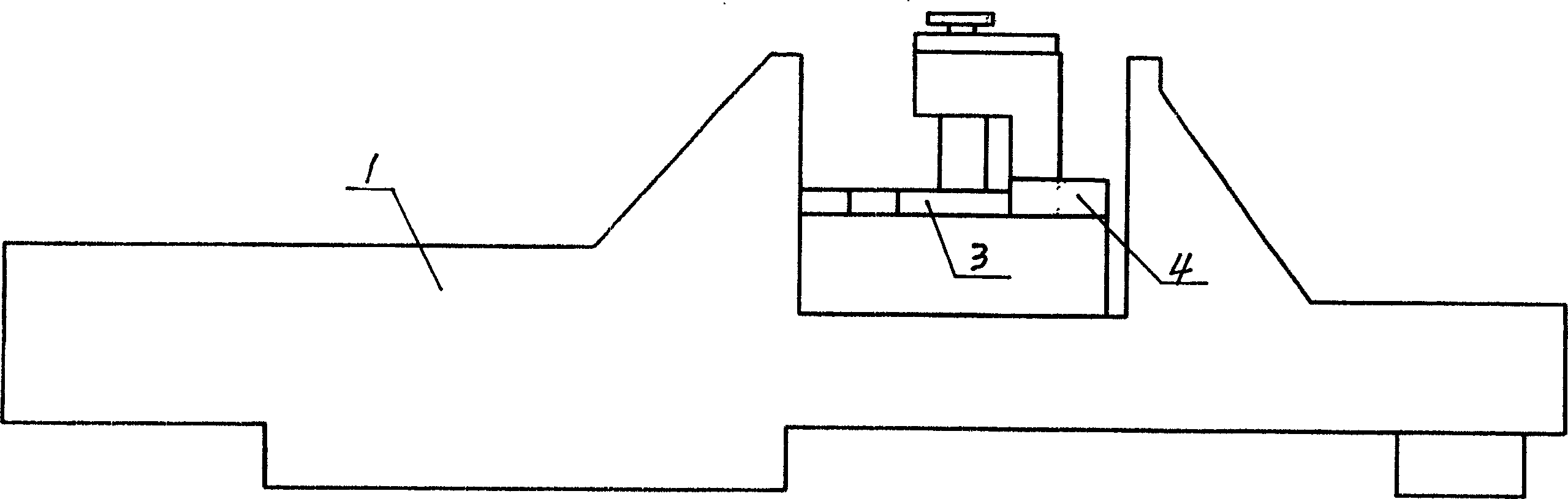

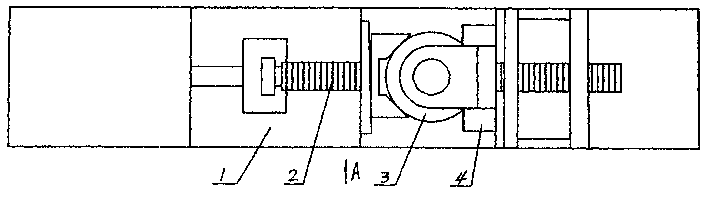

[0013] Accompanying drawing has provided the structural representation of the present invention. If two rectangular concave teeth that are X-shaped are processed on the end face of a workpiece 3, according to the process method of the present invention, a L6120 broaching machine 1 is reformed, and a set of design and manufacture has the ability to position and guide the broach, and to make the broach The fixture 4 with clamping device for dual positioning of the workpiece is fixed on the broaching machine 1, and a set of single-side cutting rectangular broach 2 is designed and manufactured. Fix the jig 4 on the broaching machine 1, the broach 2 is installed in the clamp body of the jig 4, and its head is installed on the chuck of the broaching machine 1. When working, retract the guide neck part of the broach 2 to the position of the workpiece 3, the edge of the broach 2 faces upwards, and the cut part of the workpiece 3 faces downwards, after positioning and clamping the work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com