Bulletproof safety tyre

A safety tire and carcass technology, applied in special tires, tire parts, with independent inflatable pads, etc., can solve the problem that the self-sealing layer cannot meet the safety requirements, and it is difficult to ensure that the vehicle can quickly and safely leave the scene of the accident and other problems, to achieve the effect of stable and effective ballistic resistance, good bulletproof safety performance, and excellent product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

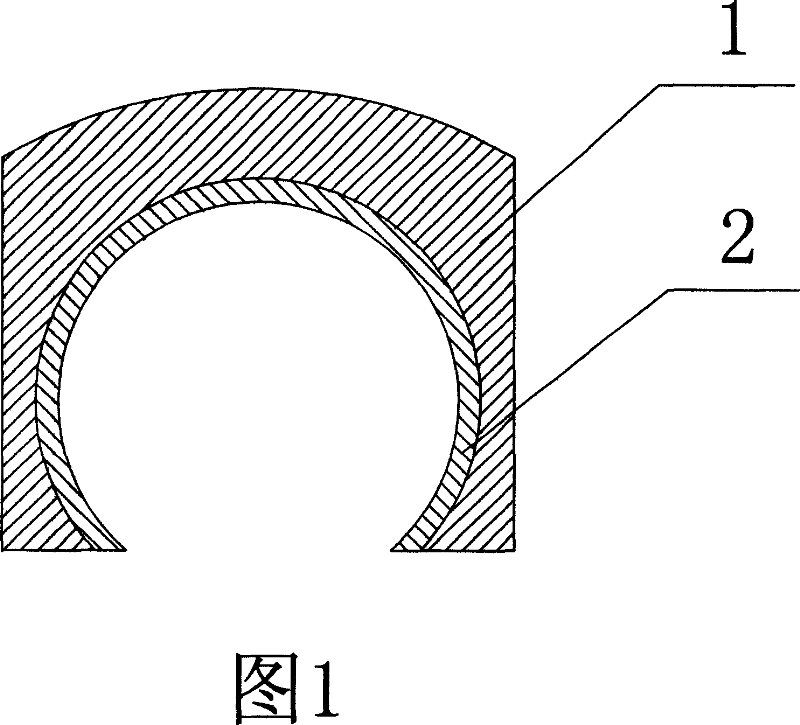

[0020] Referring to FIG. 1 , a bulletproof safety tire includes a carcass 1 and a self-sealing layer material 2 bonded to the inner lining of the carcass 1 . The preparation of bulletproof safety tire comprises (1) preparation of self-sealing layer material and (2) preparation of bulletproof safety tire:

[0021] (1) Using 100Kg of low-viscosity bromobutyl rubber and 10Kg of hydroxy-terminated nitrile liquid rubber as the main rubber, adding 10Kg of polyurethane adhesive as a reinforcing agent, and kneading at 70-80°C to obtain a self-sealing layer material.

[0022] (2) Clean and treat the inner cavity of the tire (including the crown and sidewall), and then fill the inner cavity with a self-sealing layer. The thickness of the coating is controlled at 4mm, and the coating is formed at 30-50°C.

Embodiment 2

[0024] Referring to FIG. 1 , a bulletproof safety tire includes a carcass 1 and a self-sealing layer material 2 bonded to the inner lining of the carcass 1 . The preparation of bulletproof safety tire comprises (1) preparation of self-sealing layer material and (2) preparation of bulletproof safety tire:

[0025] (1) Using 100Kg of low-viscosity bromobutyl rubber and 15Kg of hydroxy-terminated nitrile liquid rubber as the main body of rubber, adding 50Kg of polyurethane adhesive as a reinforcing agent, and kneading at 70-80°C to obtain a self-sealing layer material.

[0026] (2) Clean and treat the inner cavity of the tire (including the tire crown and sidewall), and then fill the inner cavity with a coating. The thickness of the coating is controlled at 5mm, and the coating is formed at 50-70°C.

Embodiment 3

[0028] Referring to FIG. 1 , a bulletproof safety tire includes a carcass 1 and a self-sealing layer material 2 bonded to the inner lining of the carcass 1 . The preparation of bulletproof safety tire comprises (1) preparation of self-sealing layer material and (2) preparation of bulletproof safety tire:

[0029] (1) Using 100Kg of low-viscosity bromobutyl rubber and 5Kg of hydroxy-terminated styrene-butadiene liquid rubber as the rubber body, adding 5Kg of polyurethane adhesive as a reinforcing agent, and kneading at 80-120°C to obtain a self-sealing layer material.

[0030] (2) Clean and treat the inner cavity of the tire (including the tire crown and sidewall), and then fill the inner cavity with a coating. The thickness of the coating is controlled at 3mm, and the coating is formed at 50-70°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com