Film for pressure roller

A pressure roller, film technology, applied in thin material processing, electric recording process applying charge pattern, equipment for applying electric recording process of charge pattern, etc. Weak strength and other problems, to achieve the effect of excellent release, reduce the number of production steps, and improve the sliding properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

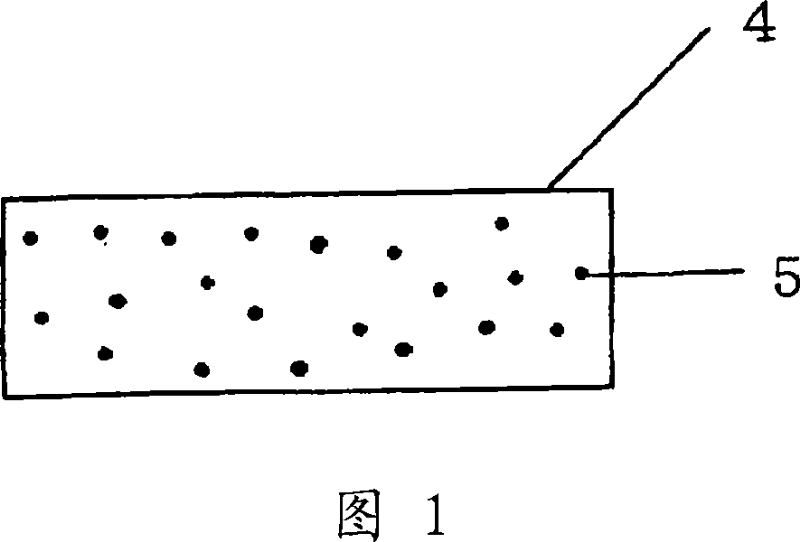

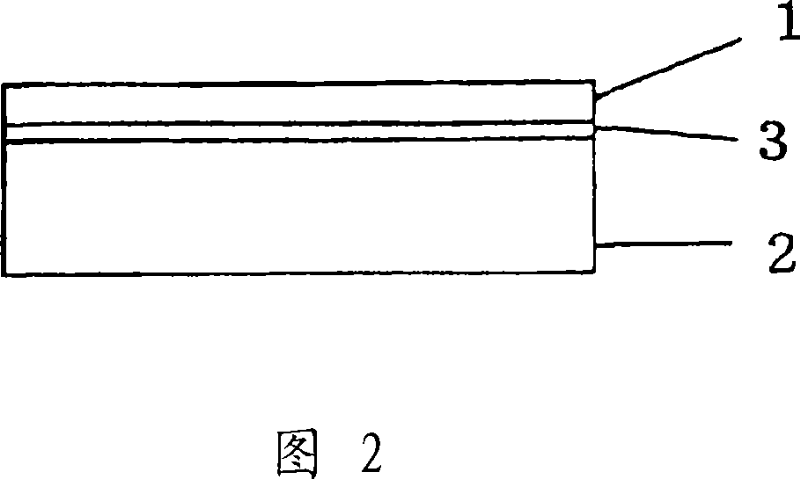

Image

Examples

Embodiment 1

[0039] Use product model MP-311 tetrafluoroethylene perfluoroalkoxyethylene copolymer (PFA, average particle diameter about 10 μm) manufactured by Mitsui Dupont Fluoro Chemical Co., Ltd., and add products manufactured by Ube Industries, Ltd. Model is the polyimide paint of U-ワニニス S301, and make it be the ratio shown in table 1 relative to both total amounts.

[0040] The resulting mixture was kneaded, shaped into a cylindrical shape, and dried.

[0041] Then, it baked in the gas atmosphere of 400 degreeC for 2 hours, and obtained the film for pressure rollers.

[0042] Next, with respect to the obtained film for a pressure roll, the tensile strength in the axial direction and the circumferential direction of the pressure roll was measured using an AGS-500D tensile and compression testing machine manufactured by Shimadzu Corporation. The results are shown in Table 1.

[0043] Table 1

[0044] Sample No

[0045] Next, with respect to the film for the pressure roll,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap