Retarder

A gear reducer, gear technology, applied in the direction of gear transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of poor accuracy, difficult to achieve high reduction ratio, etc., to achieve low cost, high reduction ratio. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

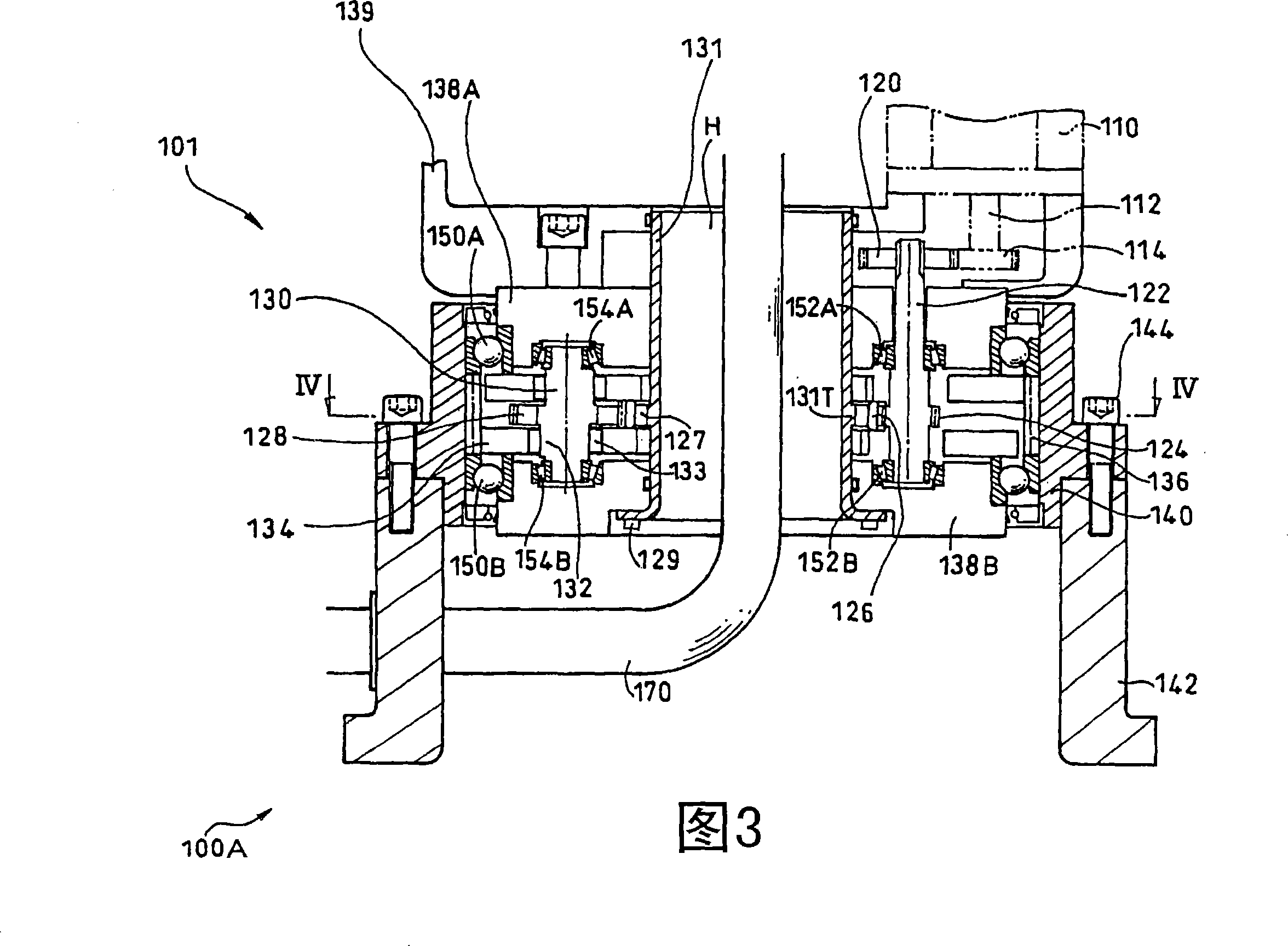

[0024] Hereinafter, an example of embodiment of the present invention will be described in detail using the drawings.

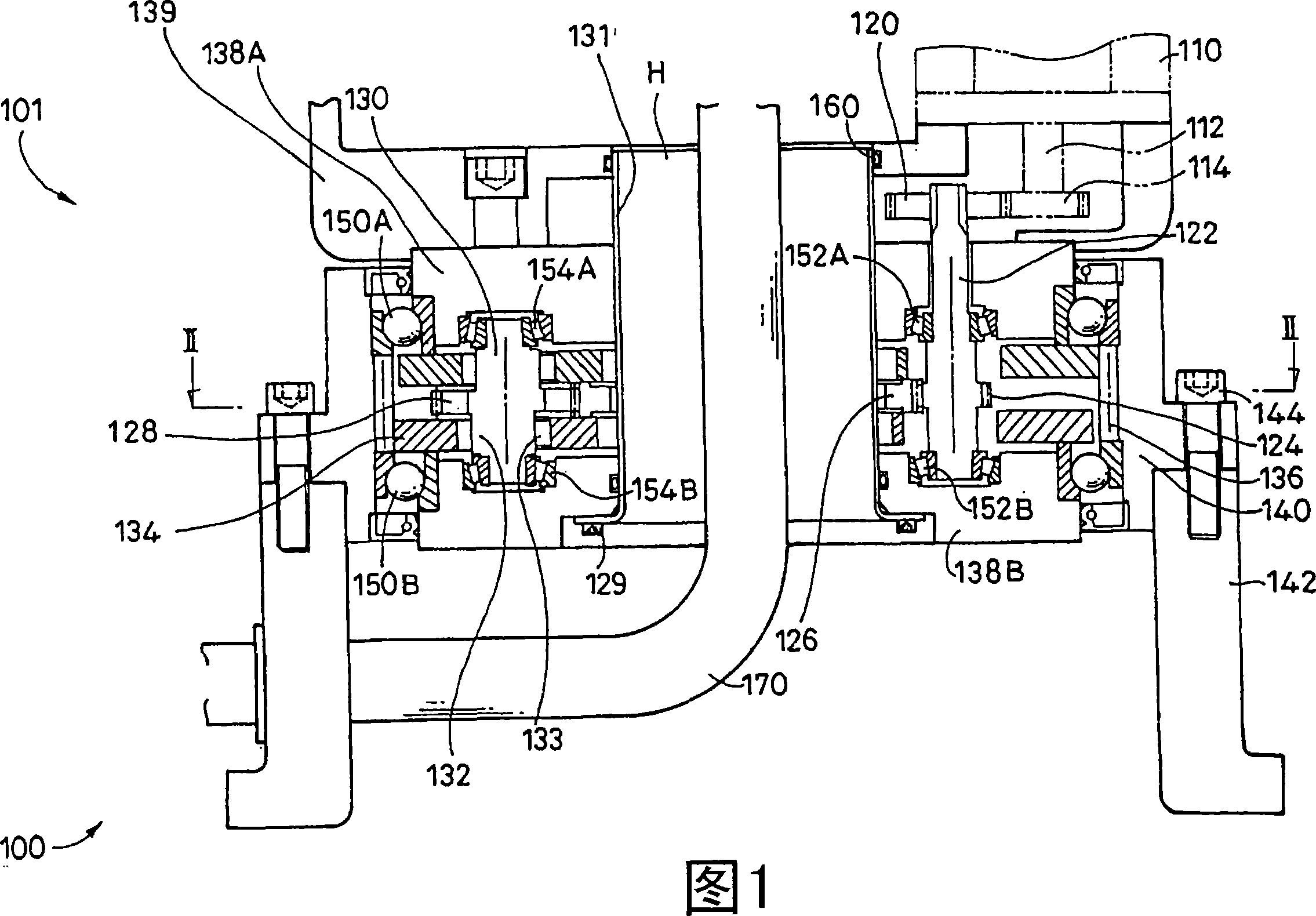

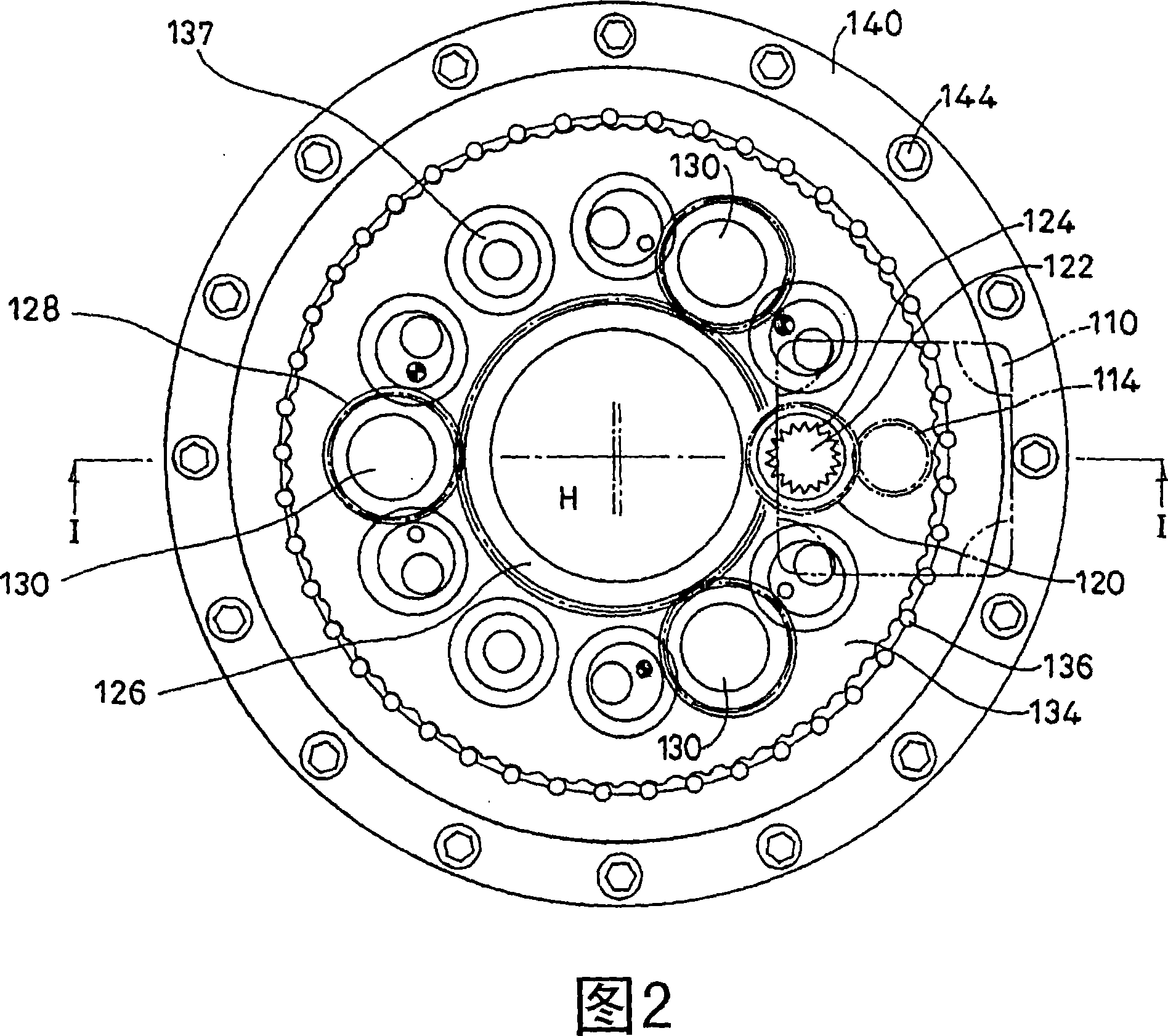

[0025] FIG. 1 is a side sectional view showing a gear motor 100 according to an embodiment of the present invention, and FIG. 2 is a sectional view taken along arrow II-II in FIG. 1 .

[0026] The gear motor 100 is composed of a motor 110 as a power source and an inscribed swing engagement type planetary gear reducer 101 . The gear motor 100 is a so-called "vertical" gear motor 100 in which its axial direction is the up-down direction. The motor 110 is provided on the upper surface side of a housing 140 for accommodating the speed reduction mechanism, and a base 142 is connected to the lower surface side of the housing 140 by screws 144 . In addition, a hollow portion H is provided in the center portion in the radial direction of the gear motor 100 , and the cable 170 or the like can be passed through the hollow portion H for use.

[0027] The air portion H...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap