Press-slide switch

A sliding switch and button technology, applied in electrical switches, electrical components, circuits, etc., can solve problems such as increased damage or misoperation, entry of foreign objects, and clamping of foreign objects, etc., to achieve a keen sense of operation, reliable operation, and shorten the pressing stroke. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

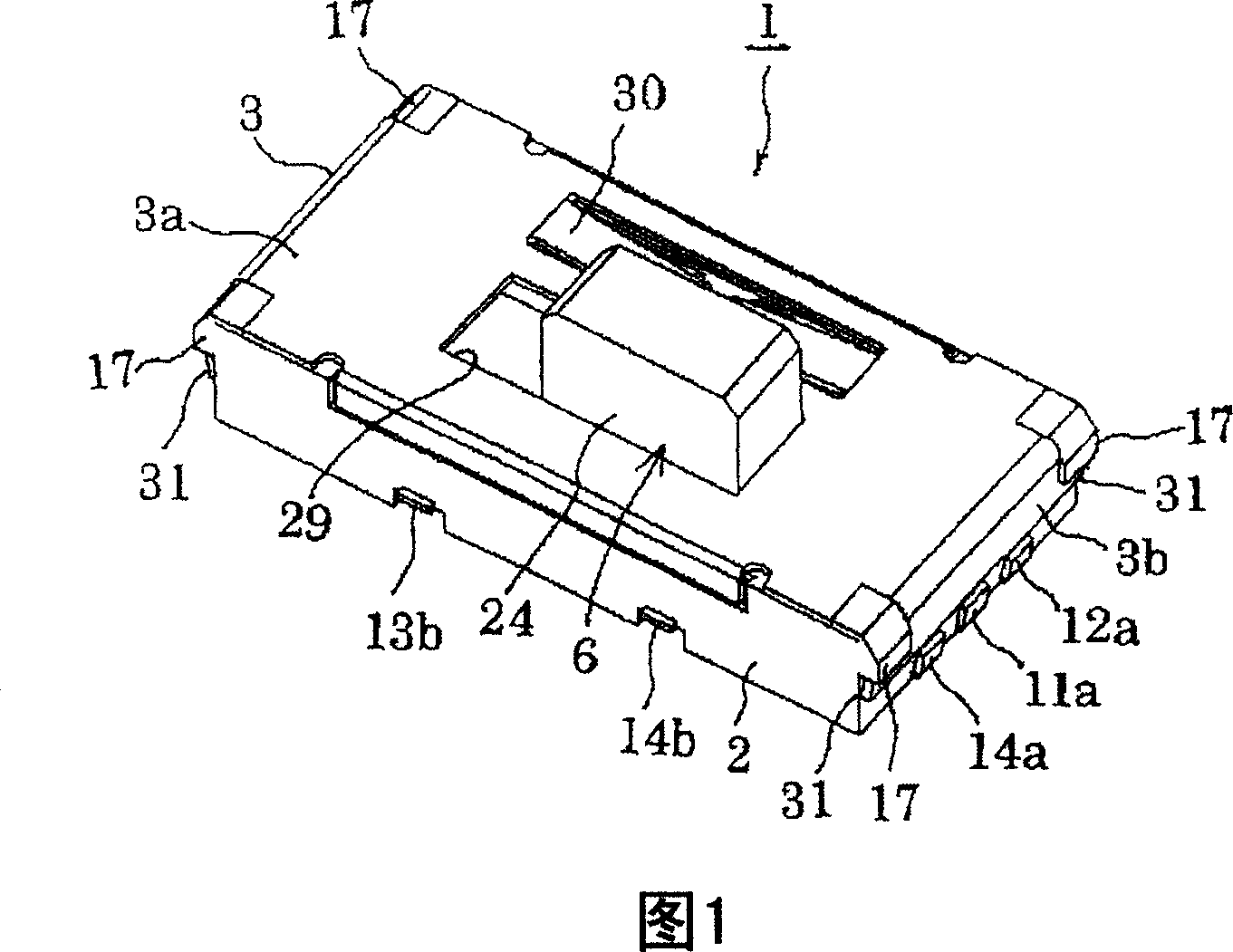

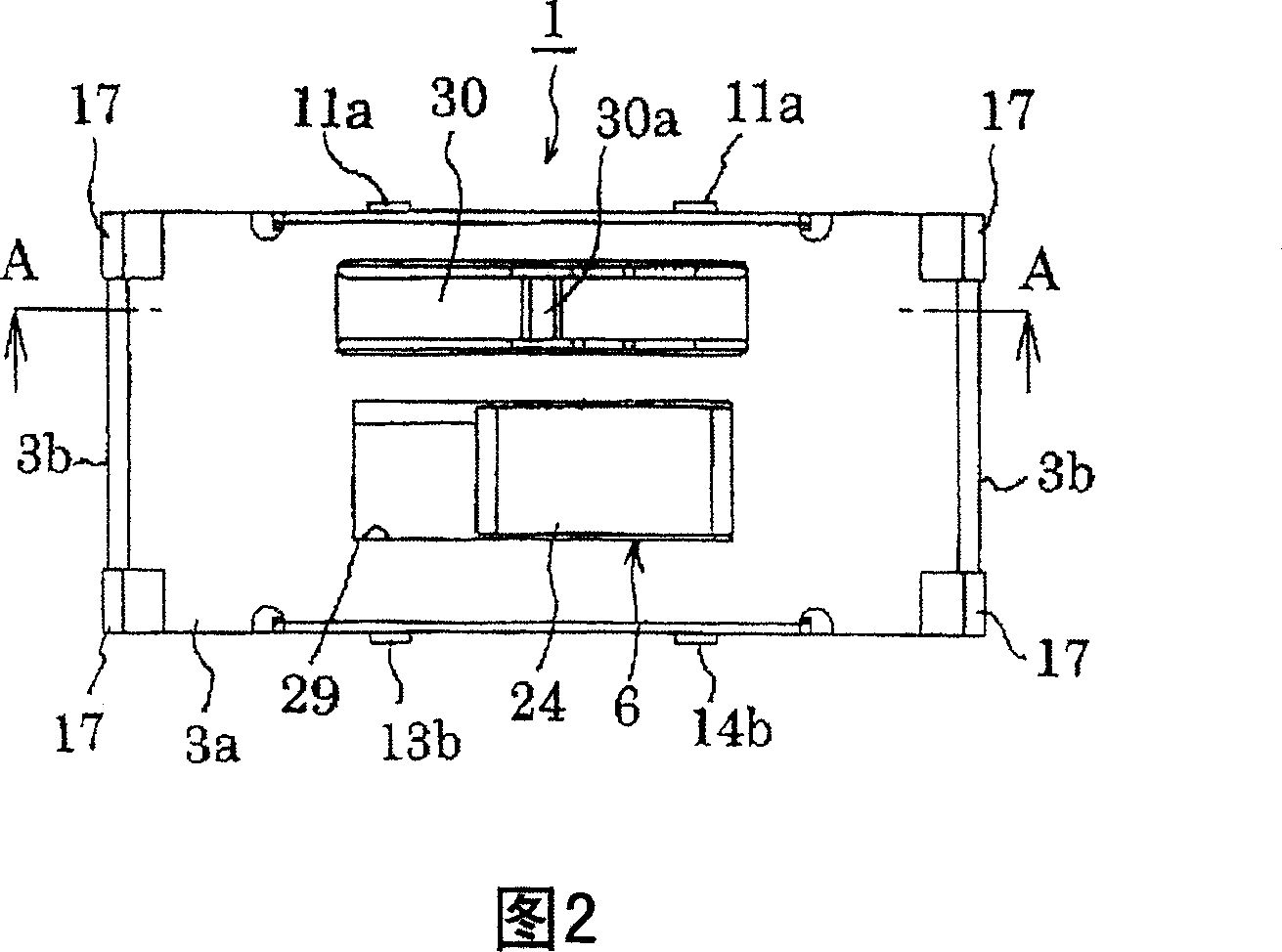

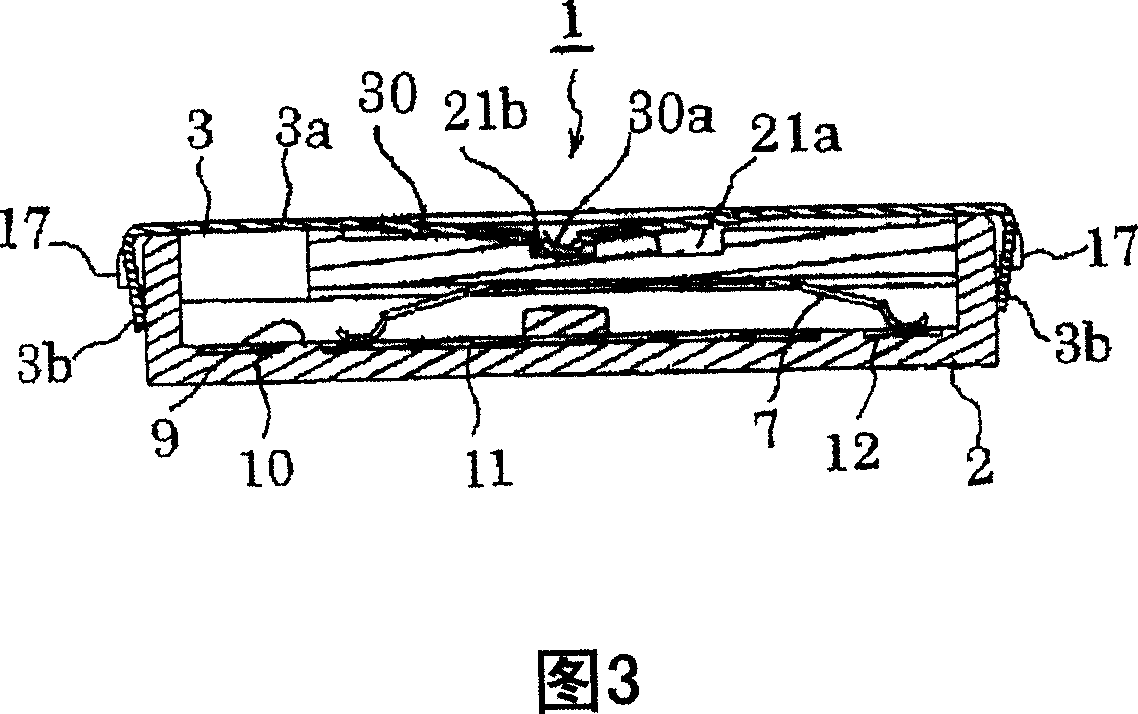

[0032] 1 to 7 show an embodiment of the present invention. As shown in FIG. 4, the push / slide switch 1 is composed of a base 2, a cover 3, an operating member 6 composed of a first operating member 4 and a second operating member 5, a sliding contact piece 7, and a disc-shaped movable contact piece 8. .

[0033] The base 2 is formed into a thin and roughly box-shaped by an insulating member such as a synthetic resin material. As shown in FIG. Arranged in a row, the fixed terminals for pressing 13 and 14 are fixed in parallel with the fixed terminals for sliding 10 to 12 by insert molding. The terminal portions 10a-12a, 11b, 11b of the sliding fixed terminals 10-12 and the terminals 13a, 14a, 13b, 14b of the pressing fixed terminals 13, 14 are drawn out of the base 2 and exposed. In addition, the fixed terminals 13 and 14 for pressing are exposed in the concave portion 15 of the inner bottom surface 9 .

[0034] 6 shows the shape and arrangement state of the sliding fixed te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com