Ball-and-socket joint

A ball joint, spherical technology, applied in the direction of connection, pivot connection, shaft and bearing, etc., can solve problems such as loosening and failure, and achieve the effect of preventing torsion, improving torsion prevention, and stabilizing and preventing torsion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

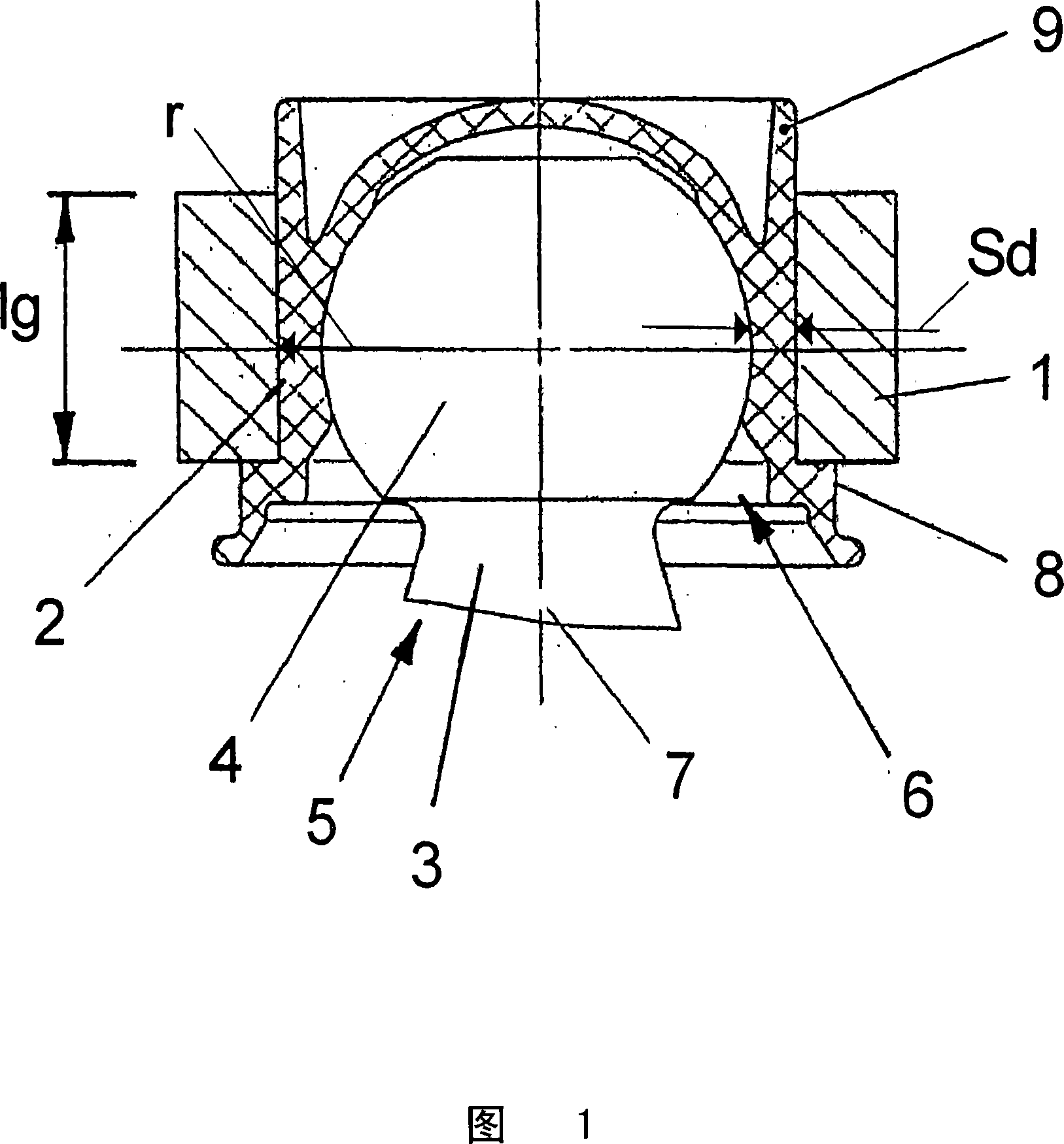

[0035] According to FIG. 1 , a bearing shell 2 is inserted in an annular housing 1 , in which a ball pin 5 with a journal 3 and a joint ball 4 is slidably mounted. In this case, the ball pin 5 protrudes from the ball joint through an opening 6 provided in the bearing shell 2 and can be rotated about the longitudinal center axis 7 of the ball joint and pivoted transversely to this longitudinal center axis in the joint ball 4 Click to turn around. In the region of the opening 6 , the bearing shell 2 bears against the end face of the housing 1 via the outer shoulder 8 , whereas at the end of the bearing shell 2 facing away from the outer shoulder 8 the annular flange 9 extends from the housing 1 . Highlighted.

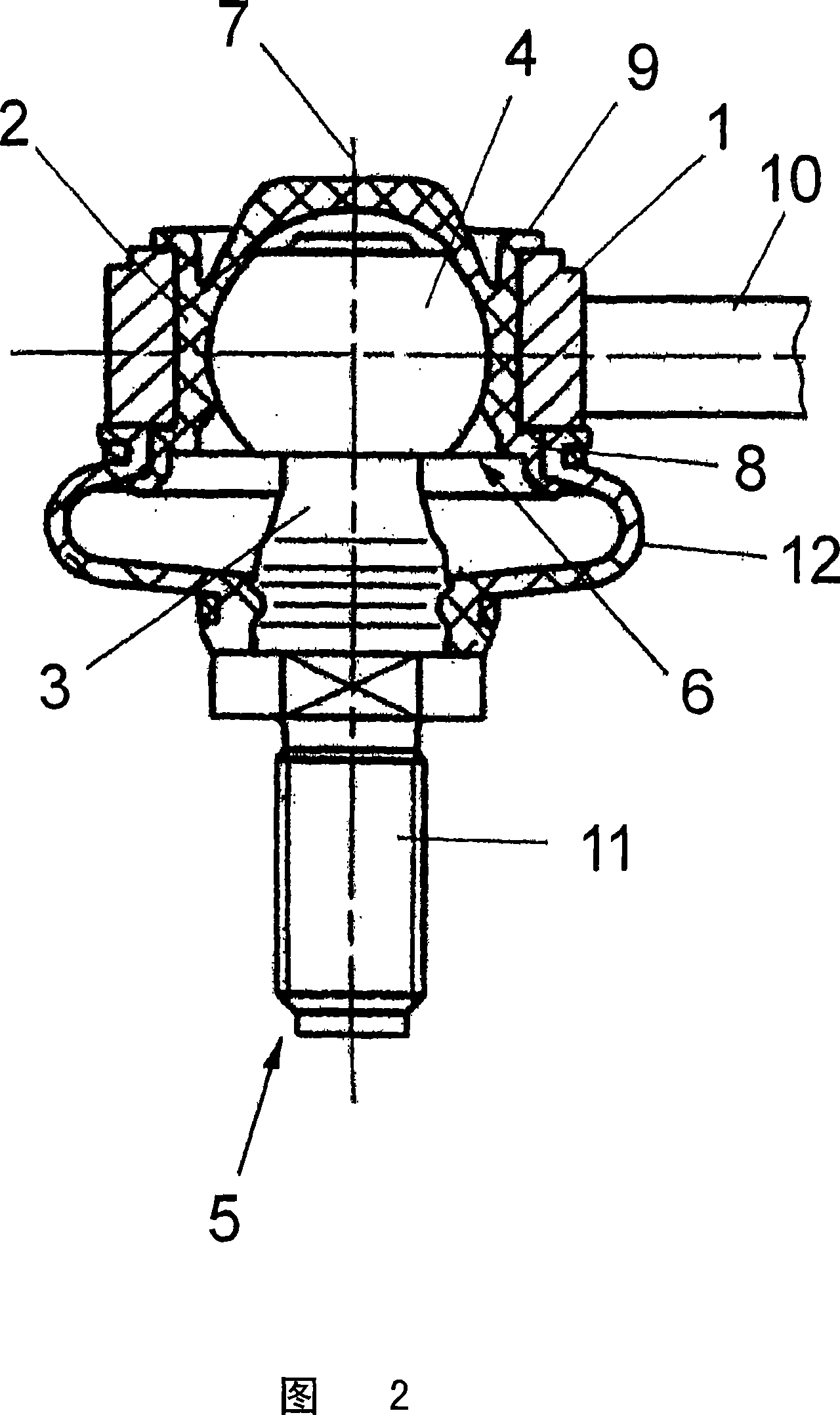

[0036] It can be seen from FIG. 2 that in order to secure the bearing shell 2 axially in the housing 1 , the annular collar 9 is turned radially outward by material deformation, wherein the turning is preferably effected using an ultrasonic deformation method. The ball ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com