Technique and equipment for mixing ore pulp in production of alumina

A kind of mixing equipment, alumina technology, applied in the direction of alumina/aluminum hydroxide, alkali metal aluminate/alumina/aluminum hydroxide preparation, mixer with rotating stirring device, etc., can solve the problem of damaging the operating environment, diluting Problems such as trough leaking, lack of steam and material, etc., to achieve the effect of protecting the operating environment, preventing slurry leakage, and ensuring airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited by the embodiments.

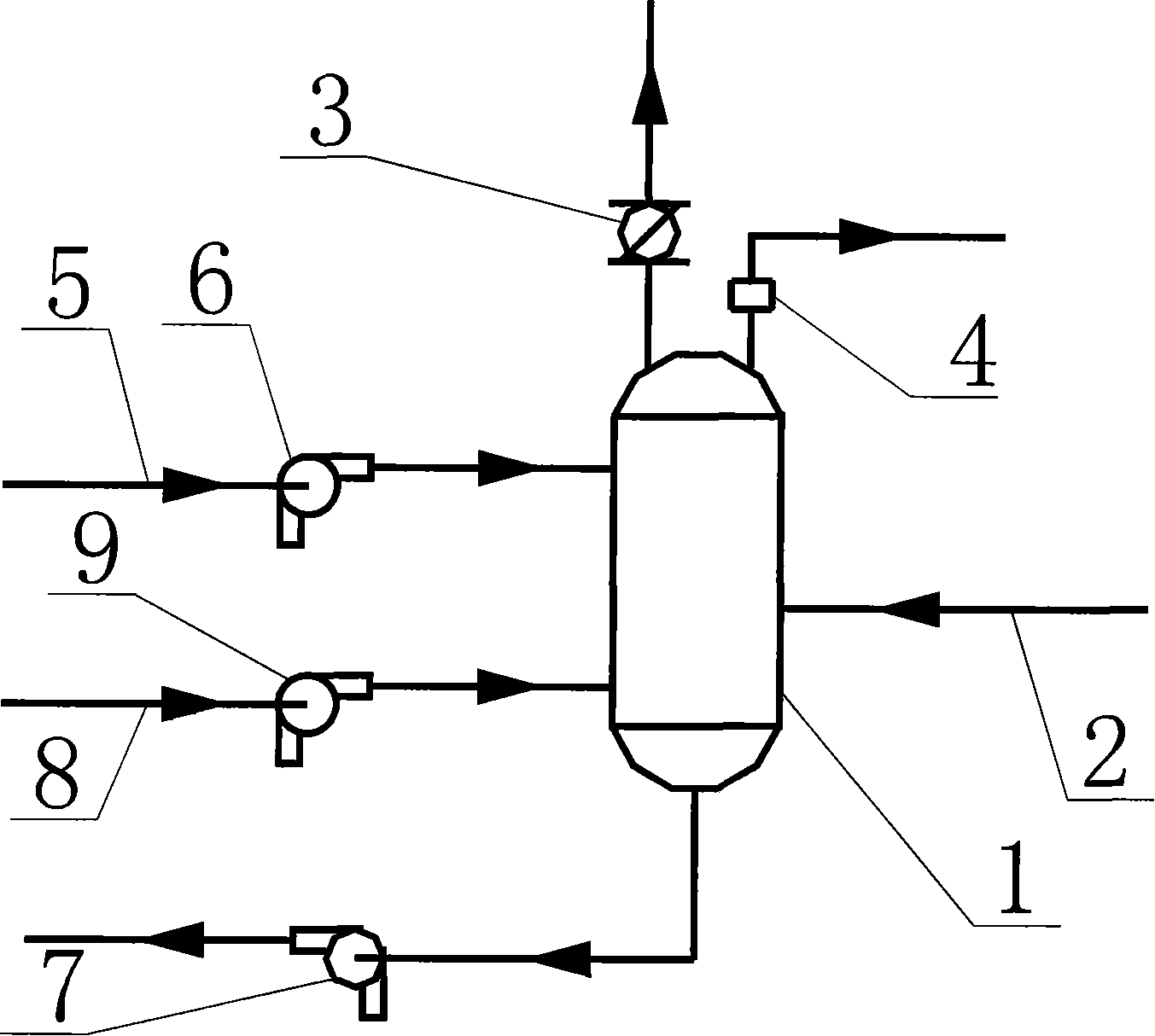

[0025] In the pulp mixing process in alumina production, the stripping pulp 2 is self-pressurized into the dilution tank 1, and the red mud washing liquid 5 sent by the delivery pump 6 and the aluminum hydroxide washing solution 8 sent by the delivery pump 9 are in the dilution tank 1. Effective mixing is carried out inside, and the mixed and diluted diluted slurry is transported to the red mud separation and washing process through the delivery pump 7.

[0026] Such as figure 1 Shown, the slurry mixing equipment in alumina production of the present invention, structure is as follows:

[0027] Replace the dilution tank with a dilution tank. A spiral ascending plate is installed in the dilution tank to slow down the flow rate of the secondary steam and effectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com