Electronic clutch type driver for electronic lock

A driving device and clutch-type technology, applied in the field of locks, can solve the problems of loss of flexibility, short service life, pulling of inner and outer clutch sleeves, etc., and achieve the effects of fast opening speed, long service life and high torque bearing force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

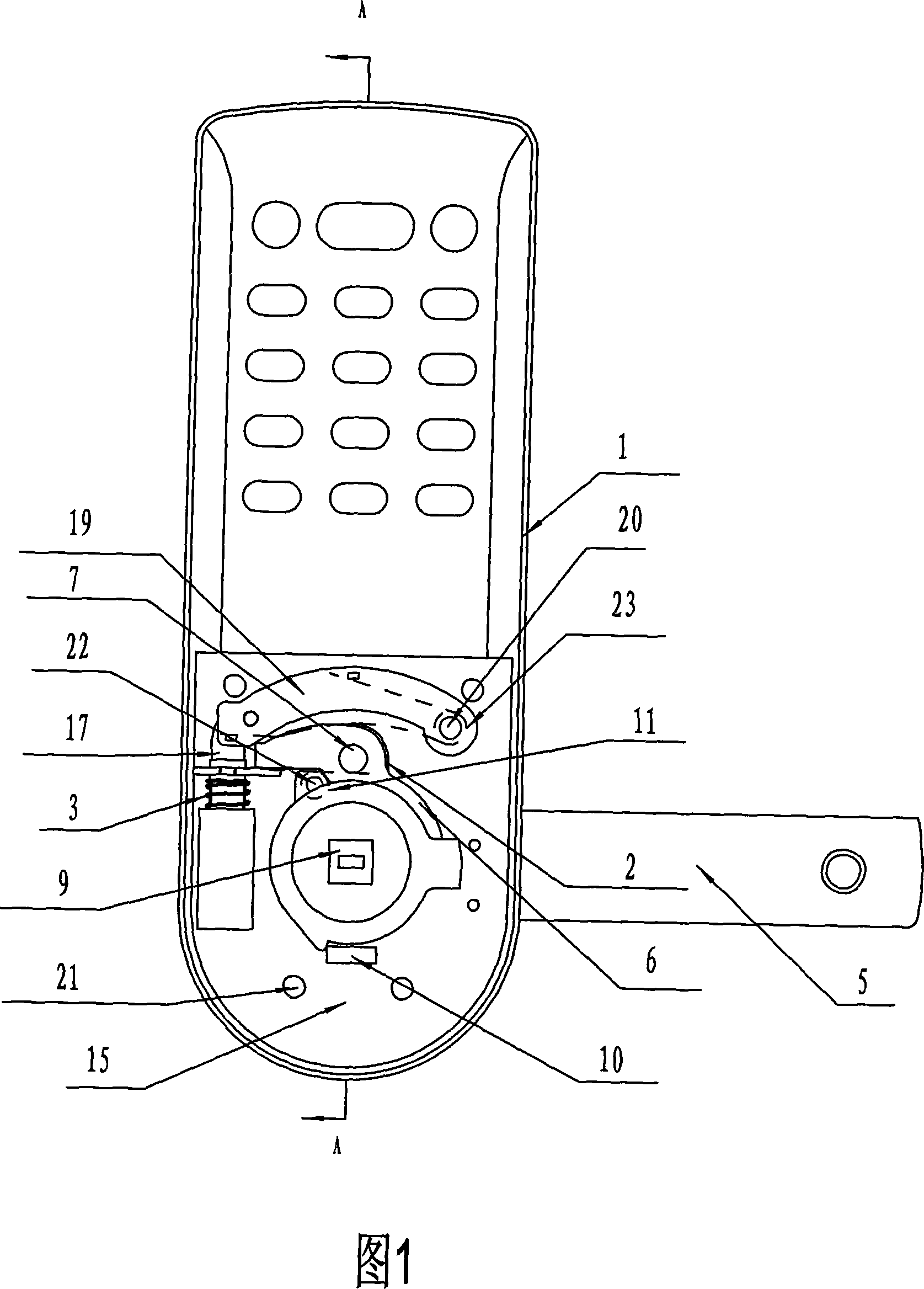

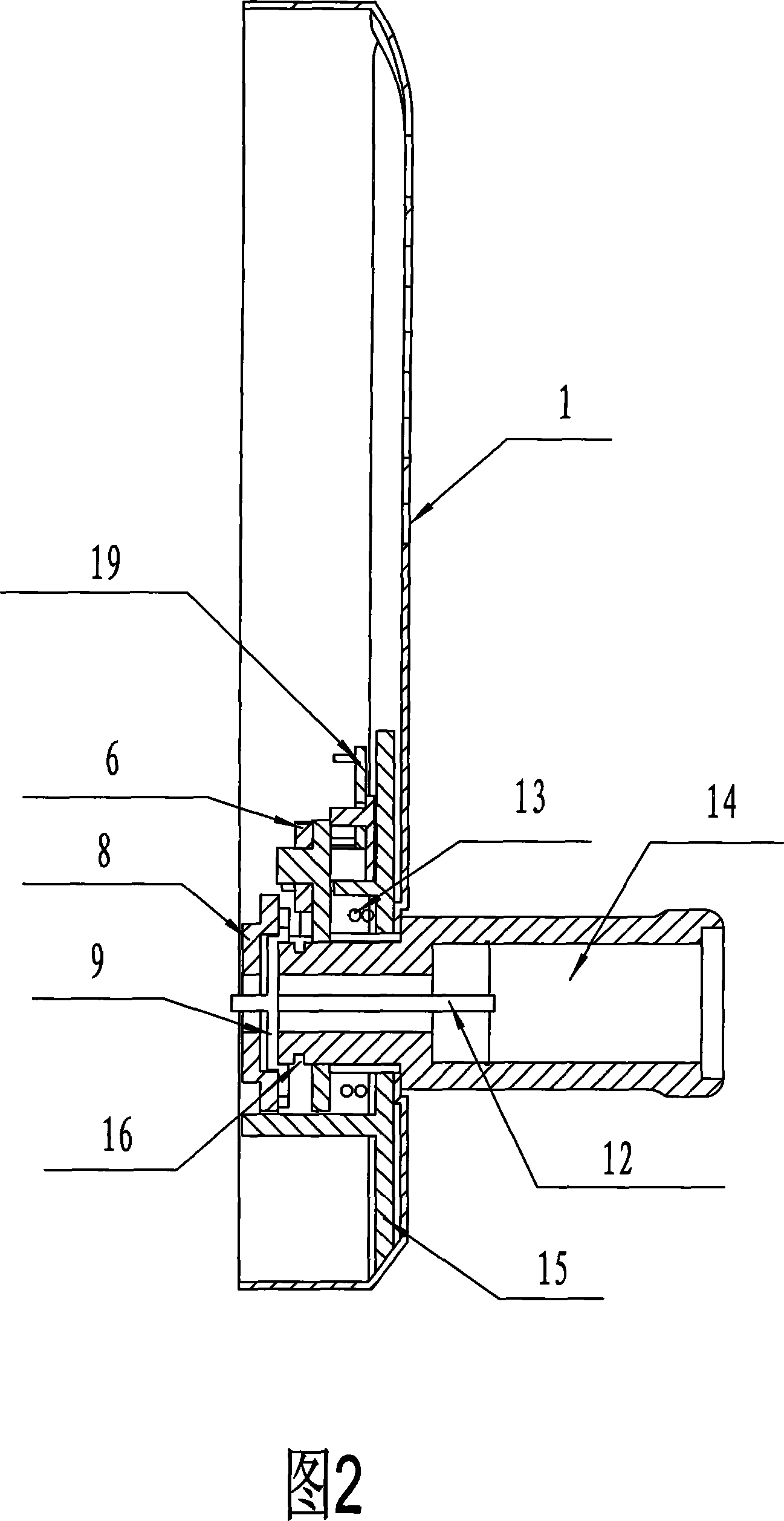

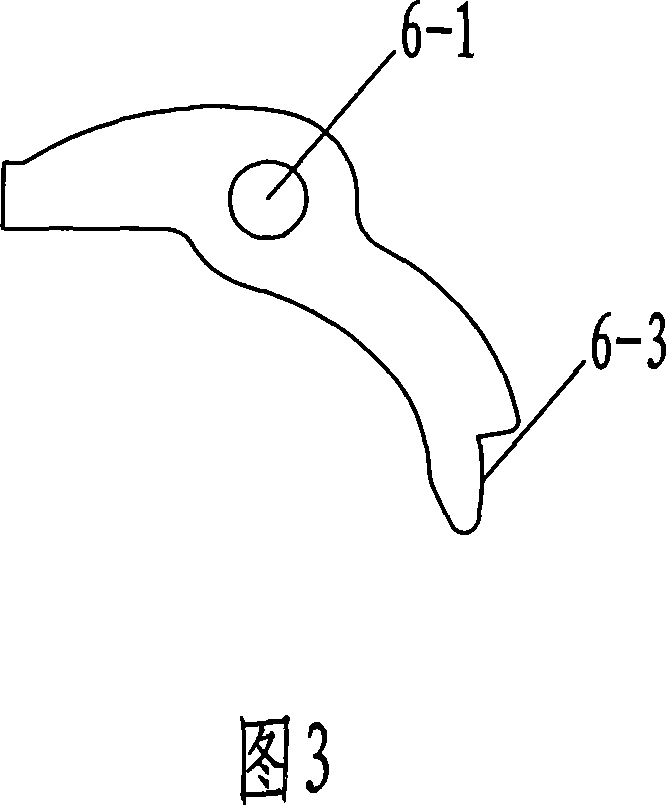

[0038] Embodiment 1: This electronic lock electronic clutch driving device mainly includes an outer panel 1 and a handle 5 , the outer panel 1 is provided with a fixing screw hole 21 , and the outer panel 1 is fixedly connected with a liner 15 . The 5 shafts of the handle are fixedly connected with a handle spline buckle 2, the handle spline buckle 2 is provided with a square bar spline keyboard 8, and the handle spline buckle 2 is connected with a clutch buckle 6 through a clutch pin shaft pin 7, and the clutch buckle One end of 6 is provided with clutch buckle card groove 6-3, is provided with square rod hole 8-1, flower keyboard card groove 8-2 and flower keyboard folding edge 8-3 on the square bar flower keyboard 8, wherein flower keyboard card groove 8 -2 cooperates with the positioning block 10 on the lining plate 15, and the flower keyboard flange 8-3 is clutched with the clutch buckle slot 6-3; the output shaft of the electromagnet 4 is provided with a connecting piece ...

Embodiment 2

[0045] Embodiment 2: The difference from Embodiment 1 is that there is no lock core structure, only an electromagnet structure. This structure is relatively simple. The lock core part is removed from the drawing of Embodiment 1. This electronic lock electronic clutch driving device mainly includes an outer panel 1 and a handle 5. The handle 5 is fixedly connected with a handle spline buckle 2. The key buckle 2 is connected with the clutch buckle 6 through the clutch buckle pivot pin 7, one end of the clutch buckle 6 is provided with the clutch buckle card slot 6-3, and the square stick flower keyboard 8 is provided with the square stick hole 8-1, the flower keyboard card Groove 8-2 and keypad flap 8-3, wherein keypad card slot 8-2 cooperates with positioning block 10 on the outer panel, keypad flap 8-3 and clutch buckle slot 6-3 are clutch type Cooperate; the output shaft of the electromagnet 4 is provided with a connecting piece 17 and an electromagnet spring 3, the connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com